Vibrating Sieve for Powder

What is Vibrating Sieve for Powder?

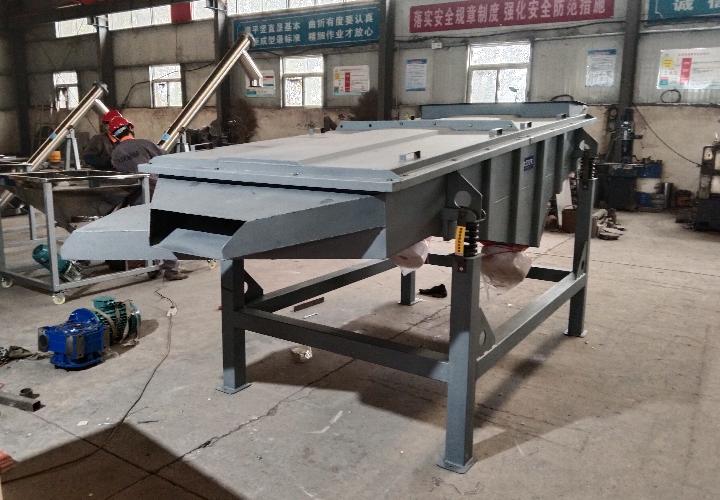

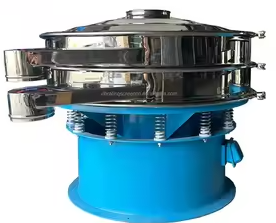

Vibrating Sieve for Powder is commonly used for powder classification and screening. It uses a vibrating motor to generate excitation force, causing powder materials to be thrown up and moved forward on the screen surface, thereby achieving separation of different particle sizes. The screening mesh size is usually 20-500 mesh, and the output is 0.1-20 tons/hour. The equipment has the characteristics of high screening accuracy, good sealing, easy cleaning, and multi-layer screening.

Vibrating sieve for powder is a special term for the screening of powder materials in various industries. In order to maintain the accuracy, the powder will be screened. For example, the powder in the pharmaceutical and food industries needs to be isolated from external pollution, and the chemical and metallurgical industries need to prevent material It can be seen that the sealing treatment of the vibrating sieve for powder equipment must be in place. How to achieve the sealing treatment?

Material and model specifications of vibrating sieve for powder:

The material is mainly divided into three types:

The part in contact with the material is made of stainless steel, and the bottom cylinder is made of carbon steel;

All stainless steel, and the bottom cylinder is also made of stainless steel;

All carbon steel, the part in contact with the material is also made of carbon steel.

For corrosive materials that cannot be satisfied by stainless steel, Jinhe has launched a plastic material vibrating sieve. Models are divided into: XZS series, S49 series, JH series, diameter 600-1800mm, 1-3 layers of multi-level screening, more space for selection.

Vibrating Sieve for Powder Classification

Vibrating screens for powder are divided into stainless steel vibrating screens and ultrasonic vibrating screens. These two types of vibrating screens are classified according to different principles, focusing on specific application areas and core advantages.

The stainless steel type, primarily manufactured from stainless steel, offers advantages in corrosion resistance and hygiene, preventing chemical reactions between powder and metal, while facilitating easy cleaning and disinfection. It is used in industries such as food and pharmaceuticals, where material hygiene requirements are stringent, such as flour screening and pharmaceutical powder grading.

The ultrasonic type integrates an ultrasonic system on top of traditional vibrating screening. Its core function is to address the problems of fine and sticky powders prone to agglomeration and screen clogging. High-frequency ultrasonic vibrations break down powder agglomerates, improving screening efficiency and accuracy. It is particularly suitable for ultrafine powder screening in the chemical and new energy sectors, such as the fine screening of lithium battery material powders and coating powders.

Advantages of Using a Vibrating Sieve for Powder

The Vibrating Sieve for Powder uses high-frequency vibration to rapidly separate powder particles, capable of separating powders of varying particle sizes. This increases throughput by 30%-50% compared to traditional screening equipment. The equipment precisely controls powder particle size, capable of separating fine powders down to 20 microns. Most equipment is constructed of stainless steel, offering a smooth, easy-to-clean surface. The simple design allows for easy assembly and disassembly, minimizing the risk of residual contamination. The vibrating motor drive system offers low energy consumption, low noise, and a low failure rate, enabling continuous operation for extended periods of time and minimizing production interruptions.

Recommended mesh size for Vibrating Sieve for Powder

When using a Vibrating Sieve for Powder, different screen sizes ranging from 10 to 400 mesh can be selected based on the particle size distribution of the material and the required screening accuracy.

Fine powder (100-400 mesh): used for screening and grading fine powder to ensure the uniformity and fineness of particles.

Medium powder (40-100 mesh): suitable for powders with medium particle size, which can effectively remove impurities and improve product quality.

Coarse powder (10-40 mesh): used for screening powders with larger particles, removing large particle impurities, and improving product uniformity and quality.

Mixed powder (different mesh sizes used in combination): For mixed powders, you can combine sieves of different mesh sizes to screen according to the specific particle size requirements to achieve the desired grading effect.

Sealing device for vibrating sieve for powder

The vibrating sieve for powder is composed of multiple parts, which can not avoid the gap between the combinations. Jinhe uses rubber or silicone rubber sealing strips for sealing treatment, and the inlet and outlet can be selected with soft The connection is to connect the cylinder to perform the connection and sealing process. There must be a dust cover for vibrating sieve for powder. In order to facilitate the observation of material sieving, please note that an observation port should be left on the dust cover at the time of purchase.

The other is the position of the spring. For example, medical vibrating sieve needs to be treated with an apron, that is, the spring is also surrounded. This can effectively prevent the internal and external dust from covering the vibration motor for a long time, which can effectively affect the service life of the motor, and the appearance will also be affected accordingly. nice.

Cleaning device for vibrating sieve for powder

The powder has different thickness and is easy to block holes. For this reason, Jinhe will install rubber or silicone bouncing balls between the mesh frame and the screen. The bouncing ball bounces and hits the screen under the effect of vibration to achieve effective net cleaning effect. . There are also some powders that have static electricity, are prone to moisture agglomeration, contain oil, and have too fine particle size. Ultrasonic vibrating sieve is recommended.

For example, powders such as sulfur powder and polyvinyl alcohol are explosive. When purchasing, you must explain to Jinhe staff. In order to avoid the danger, it is recommended to use explosion-proof vibrating sieve, which is to replace the motor of the vibrating sieve. For explosion-proof motors.

Related cases for Vibrating Sieve for Powder

|

Powder type |

recommended mesh |

range |

|

Chinese medicine powder |

80-600 mesh |

coarse powder (80-100 mesh), general powder (120-200 mesh), fine powder (300-600 mesh) |

|

Flour |

18-400 mesh |

rough impurity removal (18-20 mesh), loose sieving and block removal (24-40 mesh), fine selection (within 400 mesh) |

|

Starch |

20-400 mesh |

impurity removal (20-30 mesh), screening (50mm-400 mesh) |

|

Feed additives |

30-200 mesh |

Screening impurities (30-200 mesh), output: 300-1000kg/h |

|

Chemical powder coatings |

60-325 mesh |

Powder coating screening, select fineness according to process requirements |

|

Metal powder |

20-300 mesh and above |

Coarse screen (20-60 mesh), medium screen (80-120 mesh), fine screen (150-300 mesh and above) |

|

Alumina powder |

60-600 mesh |

Industrial grade alumina screening, single particle dispersion without agglomeration |

Precautions for using Vibrating Sieve for Powder

When choosing a Vibrating Sieve for Powder, you should pay attention to the characteristics and output of different powder materials.

Material characteristics: sticky, static or ultra-fine powders require ultrasonic vibrating screens.

Production requirements: Powder vibrating screens have a large processing capacity, while rotary vibrating screens have higher precision but smaller output.

Equipment selection: Select the model based on the powder type, fineness requirements and output.

Vibrating Sieve for Powder supplier

When selecting a powder vibrating screen supplier, you can provide the supplier with detailed specifications of the powder's characteristics, including particle size distribution, moisture content, flowability, viscosity, corrosiveness, electrostatic effects, and whether it is prone to agglomeration. Dahan Machinery manufactures equipment with options for bouncing balls or ultrasonic systems. The equipment is available in plastic, carbon steel, and stainless steel to adapt to various material properties. For special powders, explosion-proof motors are available. Customized solutions can be provided based on the specific process requirements of the materials.

For special customization, you can directly consult Dahan Machinery. The vibrating sieve sub-equipment produced by Dahan Machinery can be designed and produced to meet the needs of users, and there are many kinds of vibrating sieve sub-equipment. 14 production experience, looking forward to working with you!

-

A sesame seed sieve is a mechanical device that uses vibration and multiple layers of screens to sepa ...

-

Double deck vibrating screen price is generally between $5,000 and $20,000, and usually varies signif ...

-

Slurry sieve is a device that uses a screen as the main separation method to filter the liquid-solid ...

-

Hemp core powder vibrating screen

Hemp core powder vibrating screen is a device used to screen and separate fine particles such as hemp ...

-

Charcoal powder grading vibrating screen

Charcoal powder grading vibrating screen uses high-frequency vibration technology to screen different ...

-

Centrifugal Sifter For Our Flour

Centrifugal Sifter For Our Flour is also called cyclone sifter. It can classify the particle size of ...

-

Linear vibrating screen quartz sand

Linear vibrating screen quartz sand uses a vibrating motor as a vibration source to remove impurities ...

-

Swing Vibrating Screen Screening Petroleum Coke Powder

Swing Vibrating Screen Screening Petroleum Coke Powder has equipment types such as square swing vibra ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.