Slurry Sieve

![[field:title/]](/uploads/250603/6-2506031S503623.png)

Callback

Slurry sieve is a device that uses a screen as the main separation method to filter the liquid-solid mixed slurry on the screen surface through mechanical vibration to achieve solid-liquid separation. Its core function is to intercept larger solid particles in the slurry, protect subsequent equipment (such as desanders, desilters, centrifuges) from damage, and improve the efficiency and cleanliness of slurry recovery.

Screen specifications: 600×1200mm~1000×2000mm

Screen mesh number: 40~325 mesh

Vibration frequency: 25~50 Hz

Processing capacity: 20~150 m³/h

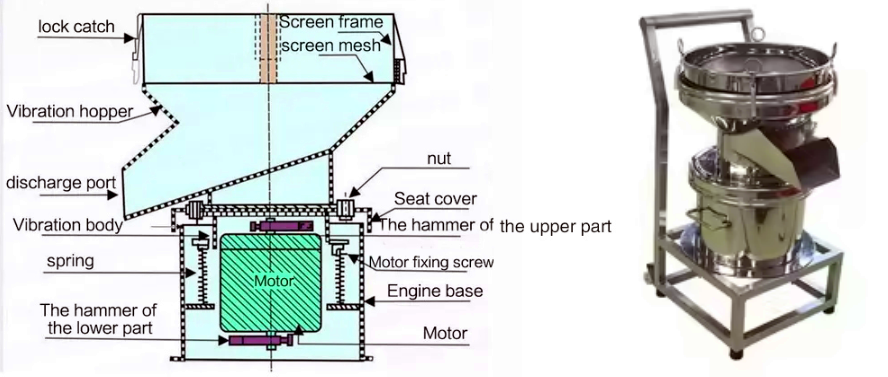

What is a slurry sieve?

Slurry has the characteristics of high concentration, high viscosity, and uneven solid-liquid mixing. The solid particles in it are of different sizes and properties. The slurry sieve uses the exciting force generated by the vibration motor to make the screen surface vibrate at high frequency, effectively overcoming the agglomeration force and surface tension between particles in the slurry. The screen is made of stainless steel, polyurethane and other materials. Different mesh sizes can be selected according to needs to accurately separate solid particles of different particle sizes.

The ideal slurry sieve should have efficient filtering capabilities, and can achieve rapid and thorough solid phase removal when processing high-viscosity and high-solid content slurry, reduce the load of subsequent processing equipment, and recover reusable slurry. The quality of the filtration effect directly affects the performance maintenance of the slurry, the operating efficiency of the equipment and the final processing cost.

What are the main functions of the slurry sieve?

The slurry sieve is a high-efficiency filtration equipment designed for processing viscous slurries. Its core is to use a screen with a specific aperture to force liquid slurry through the screen hole through mechanical vibration and other methods, while retaining solid particles larger than the size of the screen hole (such as rock cuttings, sand particles, etc.) on the screen, thereby achieving the purpose of solid-liquid separation. Its core functions include:

Solid-liquid separation: remove solid impurities (such as drill cuttings, sand and gravel) in the slurry and recover liquid (such as drilling fluid, slurry).

Particle size classification: grade and screen solid particles according to the screen aperture.

Recycling: In industrial production (such as ceramics, food, and chemicals), the purified liquid can be reused to reduce costs.

The difference between a slurry sieve and an ordinary vibrating slurry sieve

A slurry sieve usually refers to a simple screening device that mainly relies on gravity or vibration to separate solid particles in the slurry through a screen, and is suitable for processing large flows of slurry. Mud screens usually combine a variety of separation technologies, such as vibration and centrifugation, and have higher separation efficiency and processing capacity, and may include multiple screens and separation units.

|

Comparison project |

Slurry sieve |

Ordinary vibration slurry sieve |

|

Image |

|

|

|

Core function |

Mainly used for fine filtering of solid impurities in slurry |

Mainly used for primary screening of large particles in slurry |

|

Filtering accuracy |

Can reach 500 mesh (25μm) or even higher |

40-200 mesh (74μm and above) |

|

Applicable slurry type |

Mud with high viscosity and more fine impurities |

Mud with high solid content but larger particle size |

|

Vibration form |

Mostly high-frequency vibration or elliptical motion, which is convenient for fine particle separation |

Mostly linear vibration |

|

Equipment structure |

Usually multi-layer screen with fine particle separation or pressure compensation structure |

Generally single-layer screen with compact structure |

|

Filtering accuracy |

High, can filter fine solids, micro-sand, etc. |

Low, mainly for larger solid particles |

|

Solid moisture content |

extremely low (15%-25%, close to the "slurry cake" state) |

higher (30%-50%) |

|

Treatment purpose |

improve the quality of slurry circulation, protect subsequent precision equipment |

preliminary removal of large particles such as drill cuttings, sand and gravel |

What is the working principle of the slurry sieve

The slurry is transported to the feed port of the filter screen through the slurry pump. Under the action of the screen surface:

The liquid part (finer particles and water) passes through the screen, enters the lower collection tank, and re-enters the circulation system;

Solid particles (drill cuttings, sand and gravel, cementing materials, etc.) are trapped on the surface of the screen and automatically discharged through the screen surface inclination and vibration. The vibration is generated by an eccentric motor or exciter, usually horizontal or elliptical trajectory movement to enhance the screening efficiency.

What are the advantages of slurry filter sieves?

Finer filtration effect: Mud screens usually use filter media with smaller pores and higher precision (such as finer wire mesh, filter cloth and other multi-layer composite structures), which can remove smaller solid particles that are difficult to separate with ordinary vibrating screens.

Improve the efficiency and life of downstream equipment: By removing more fine solid particles, slurry filter screens can reduce the processing load of subsequent solid control equipment, improve their processing efficiency, and reduce the wear caused by fine abrasive solids, thereby extending the service life of the equipment.

Higher slurry recovery rate: Some sophisticated slurry filter screen designs, such as using more optimized fluid dynamic structures or more effective filter cake stripping mechanisms, may be able to achieve fine filtration while reducing the amount of liquid carried away with waste residues, thereby improving the recovery rate of slurry and reducing slurry consumption.

Adapt to more special application scenarios: For some specific applications with extremely high requirements for slurry cleanliness, such as some special drilling processes or slurry treatment in non-petroleum industries, slurry filter screens can provide higher quality solid-liquid separation.

Recommended mesh size of slurry sieve

|

Application scenario |

Recommended mesh size range |

Description |

|

Primary screening for oil drilling |

60~120 mesh |

Mainly removes large particles such as drill cuttings and gravel |

|

Non-excavation/jacking slurry and water separation |

80~200 mesh |

Generally requires medium precision, intercepts clay particles and cementing debris |

|

Environmental sludge filtration |

120~200 mesh |

Remove organic impurities and fine suspended matter |

|

Shield slurry recovery |

150~250 mesh |

Need to filter fine powder and micro sand to maintain slurry cleanliness |

|

Tailing slurry treatment |

100~200 mesh |

Separate metal tailings or other slag fine particles |

Technical parameters of slurry sieve

|

Model |

screen diameter (mm) |

screen layer number |

vibration frequency (r/min) |

power (kw) |

output (l/h) |

|

DHG-600 |

560 |

1 layer |

3000 |

0.4 |

800 |

|

DHG-800 |

760 |

0.25 |

500 |

||

|

DHG-1000 |

950 |

0.4 |

800 |

||

|

DHG-1200 |

1150 |

0.4 |

1200 |

What is the purpose of slurry sieve?

Slurry screen is an important equipment widely used in many industries. It is mainly used to separate solid particles in slurry to improve the purity and fluidity of the liquid. In the oil drilling industry, slurry sieve is used to treat drilling fluid, remove solid matter generated during drilling, and ensure the effective circulation of drilling fluid and the normal operation of equipment. In addition, in the mining field, slurry sieves are used to separate slurry from ore, helping to improve the extraction rate and purity of ore, reduce waste generation, and optimize resource utilization. In addition to oil and mining, slurry sieves also play an important role in the construction industry. In the production process of concrete and mortar, slurry sieves can effectively remove impurities and ensure the quality of building materials.

-

Millet vibrating sieve is widely used in millet processing industry, including millet processing plants, rice flour plants, rice......

-

Vibro Sifterfor Powdered Sugar

Powdered sugar vibro sifter is a device for screening sugar powder. It uses vibration to divide sugar

-

Powder Coating Ultrasonic Sieving Machine

The screening accuracy can be increased by 1-70%, and the output can be increased......

-

Screening machine is a mechanical equipment that uses physical separation technology to classify, remove impurities or accurately sort granular, powdery or block materials.

-

Tea sieving machine is a kind of equipment specially used for grading, removing impurities and sieving tea leaves, which is commonly used in tea processing, packaging and other links. The equipment can separate tea leaves of different specifications through multiple layers of screens......

-

How to Apply Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine is a fine powder sieving machine with relatively perfect te ...

-

Sunflower seeds screening machine

Sunflower seed screening machine, also known as sunflower seed vibrating screen or separator, is a special equipment ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration ...

-

Sweet potato powder screening machine

The Sweet potato powder screening machine effectively screens, filters and removes sweet potato starch to ensure the quality ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.