Slag powder Vibrating Screen

Slag powder Vibrating Screens are screening devices used for slag powder. They address the characteristics of fine particles, high flowability, easy agglomeration, and high dust content, completing screening and grading in continuous operation. The processing capacity of slag powder is generally between 1 and 20 tons per hour, and can be configured according to the production line scale. Screen mesh sizes are mostly in the range of 80 to 200 mesh, achieving a balance between throughput and screening quality. The equipment typically has 1 to 5 grading layers, capable of separating materials into 2 to 6 particle size grades in one pass, reducing intermediate steps and making the process smoother. The entire machine and parts in contact with the material are mostly made of carbon steel or 304 stainless steel, possessing wear and corrosion resistance, and are less prone to impurities, making them suitable for long-term continuous production.

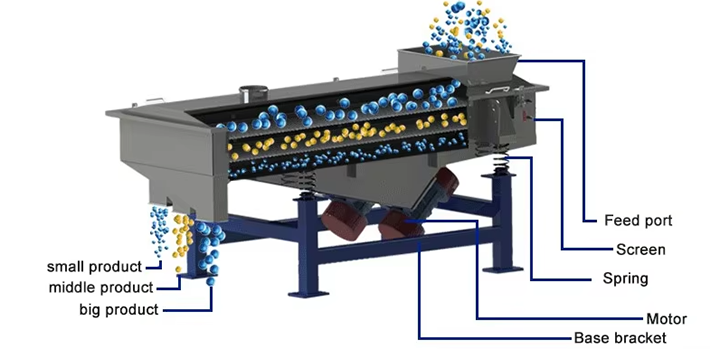

Slag Powder Vibrating Screen Components

The slag powder vibrating screen consists of a screen box, vibrating motor, screen mesh, vibration damping device, frame, and inlet/outlet ports. The equipment typically ranges in length from 2 to 4 meters and in width from 0.5 to 1.5 meters, adjustable according to site space and production requirements. The overall height is generally 1 to 1.8 meters, facilitating installation, maintenance, and routine cleaning. Its weight ranges from approximately 500 to 2000 kilograms; larger models have greater processing capacity but also heavier weights. The power unit uses a vibrating motor with power ranging from 0.75 to 3 kilowatts, providing stable vibration amplitude and continuous power for slag powder screening. The screen mesh is typically made of wear-resistant stainless steel woven mesh or polyurethane material, with uniform openings to prevent clogging and reduce slag powder smudging and leakage.

Advantages of the Slag Powder Vibrating Screen

The Slag Powder Vibrating Screen operates as a linear vibrating screen. Two motors rotate in opposite directions to create continuous vibration, causing the slag powder to bounce linearly back and forth on the screen surface. After grinding, slag powder has a high fineness and fluctuating moisture content, making it prone to agglomeration. Upon entering the screen, it is continuously broken up by the throwing and vibration forces, gradually forming clear stratification. Fine powder passes smoothly through the screen holes, while coarser particles are discharged along the front of the screen. This motion type offers fast screening speed and is suitable for continuous operation conditions such as steel plant slag systems and vertical mill slag powder production lines. Compared to rotary vibrating structures, the screen holes are less prone to clogging, maintaining stable operation even over long periods, and significantly reducing the frequency of shutdowns for cleaning. The overall structure is compact, with low operating noise. The enclosed screen box design reduces slag powder spillage, resulting in a cleaner workshop environment and reduced material loss.

Slag Powder Vibrating Screen Parameter Table

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Slag Powder Vibrating Screen Applications

Slag powder vibrating screens are commonly used in slag powder processing and reuse. In building material production lines, slag, after drying and vertical mill grinding, enters a vibrating screen. The screening process separates unground particles and impurities, ensuring consistent particle size in the finished product. This results in more uniform mixing performance when used in cement or concrete. When used for brick making or road base construction, the equipment outputs slag powder according to different particle sizes, improving gradation and preventing loosening after molding, leading to a more solid roadbed structure. In steel plant solid waste treatment, vibrating screens can separate metal fragments from slag for easier recycling. For wet slag with high moisture content, dewatering vibrating screens reduce moisture, facilitating transportation and storage.

Slag powder vibrating screens play a crucial role in slag powder processing. Their design takes into account the material's tendency to agglomerate, high fine powder content, and poor flowability. The vibration mode and screen aperture configuration cause the slag powder to bounce and stratify on the screen surface, reducing clogging and resulting in uniform particle size. In steel plant vertical mill and slag powder production lines, slag powder, after grinding, enters the vibrating screen; fine powder passes smoothly through the screen, while coarser particles are discharged. This results in more uniform mixing of slag powder when added to cement or concrete, leading to more stable strength and impermeability. The equipment operates smoothly with good noise and dust control, making operation and maintenance easier and allowing the production line to run for extended periods without frequent shutdowns for adjustments.

-

Double deck with incline vibrating screen

Double deck with incline vibrating screen adopts high-quality wear-resistant screen mesh and high-strength steel structure.

-

Liquid vibratory sifter is a device used to separate solid particles from liquid.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Raw sesame is often mixed with soil, sand, metal chips, glass fragments, etc. These impurities not only affect the taste.

-

Gypsum powder Vibrating Screen

The function of a Gypsum powder Vibrating Screen is to remove impurities, classify, and control the particle size of gypsum powder...

-

Feldspar powder Vibrating Screen

Feldspar powder vibrating screen continuously agitates and shakes the feldspar powder on the screen, breaking up clumps and...

-

Phosphate rock powder Vibrating Screen

Phosphate rock powder Vibrating Screens are screening devices designed to utilize the characteristics of phosphate rock powder...

-

Cement clinker Vibrating Screen

The Cement clinker vibrating screen is used in the screening of cement clinker, offering a wide range of processing capacities...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.