Flour Sifter

![[field:title/]](/uploads/211112/1-211112111039493.jpg)

Callback

| Screen size: | 0-500 mesh |

| Capacity: | 100-3300kg/h |

| Number of layers: | 1-5 layers |

SUS304 material, easy to clean inside and outside

Fully enclosed structure to prevent dust from entering and flying

It can be used in single layer and multiple layers, and 2-6 different specifications can be screened at one time

What is a flour sifter?

From the point of view of the material properties of flour, flour is easier to sieving, and there is no very high requirement for the screening capacity of the vibrating sieving machine. From the perspective of the use of flour, the main purpose of flour sieving is to remove impurities and loose flour. In order to facilitate customers to understand and purchase, the vibrating screen manufacturer (Jinhe Machinery) will introduce Flour Sifter according to the general purpose and application scenarios of flour screening.

Flour Sifter material can be divided into SUS304 stainless steel, Q235A carbon steel, PP plastic anti-corrosion design and production of three materials, users can choose the material and model of the screen according to their own material characteristics and industrial requirements.

What is a flour sifter used for?

1. Large bakery, boutique pastry processing enterprise

2. Integrated processing enterprises such as dried noodles, steamed buns, steamed buns, dumplings, etc.

3. Ready-mixed powder

4. Other food processing companies

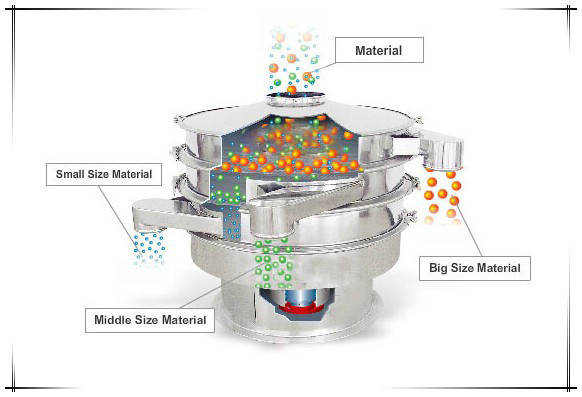

How does the flour sifter work?

The vibrating motor of the flour sifter drives the equipment to run. The flour flows through the screen of the screening equipment from the inlet. The flour smaller than the screen can pass through the screen smoothly and is discharged from the fine discharge port. The finished flour is larger than the screen. The flour of the size remains on the sieve surface and is discharged from the coarse discharge port. It is only necessary to select and replace the sieve according to the mesh number of the flour to be sieved to complete the removal and classification of the flour.

Featured videos

-

Sieving flour

-

Sieving flour (with dust-free feeding station)

What are the product screenings for Flour Sifter?

Fully automatic flour round sieve

Features: Adopting a rotating cylindrical screen, usually equipped with a motor drive, it can achieve continuous and stable screening operations.

Application scenario: Suitable for large-scale flour processing and production environments, it can significantly improve screening efficiency and output.

Output and mesh size: The output is 1-10 tons/hour, and the flour fineness can be graded (such as 40 mesh, 60 mesh, 80 mesh)

Ingredients: Flour mills, food processing enterprises, and other places that require efficient and large-scale screening

Advantages: High degree of automation, reducing the complexity and labor intensity of manual operations; High screening efficiency, able to quickly separate flour particles of different sizes; Compact structure and small footprint.

Flour test sieve

Characteristics: Flour test sieve is usually used for small-scale sample screening and detection

Application scenario: Suitable for laboratories, quality inspection departments, or small-scale flour processing environments, used for precise detection and analysis of flour composition, particle size, etc.

Yield and mesh size: The yield is 5-50kg/time, and the mesh size can be selected (40-200 mesh)

Composition: The flour screened out by the flour test mainly includes flour particles of different sizes, as well as possible impurities (such as small stones, wheat husks, insect eggs, etc.).

Advantages: High screening accuracy, suitable for precise detection and analysis of samples; It can remove impurities and improve the quality of flour.

| Equipment type | production capacity | applicable scenarios | operation mode | production capacity | mesh range |

| Fully automatic flour round screen | Large scale production | Flour mills, food processing plants | Mechanical automatic screening | High (1-20 tons/hour) | 20-300 mesh |

| Flour test sieve | small batch or experiment | R&D laboratory, small baking workshop | manual or small electric sieve | low (1-5kg/hour) | 80-300 mesh |

What are the advantages of flour sifters?

1. The sieving is fine to 500 mesh or 0.028mm, the flour has high fineness and precision, and the taste is good.

2. It is made of 304 stainless steel and polished inside and outside, which is clean and hygienic, not easy to rust, and not easy to contaminate flour.

3. Built-in special silica gel ball cleaning device for the food industry, the screen is not easy to be blocked, the powder will not stick to the screen, the screen is not easy to block, and the downtime is reduced.

4. Fully sealed structure can prevent the pollution of the environment caused by the overflow of flour.

5. 1-5 layers of screens can sort out 2-6 different grades of flour at the same time.

6. It can be operated continuously, materials can be discharged automatically in 360 degrees, and the output per hour can reach 3300kg/hour.

Technical parameters of flour sifter

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Related cases

Flour sifter equipment can be personalized or customized according to your specific needs. Whether it is small-scale household use or large-scale industrial production, we can provide efficient, accurate, and durable screening solutions. Successful case presentation

| Materials | Processing Method | Screen (mesh) |

Processing Capacity (kg/h) |

Model |

| Rice flour | Dry | 16.2 | 2000 | DH-1200-1S |

| Corn flour | Dry | 80 | 1200 | DH-2000-2S |

| Wheat flour | Wet | 200 | 3200 | DH-2000-1S |

| Flour | Dry | 24 | 1500 | DH-1000-1S |

| Case | A large flour mill | High end baking brand | Pharmaceutical intermediate factory |

| Requirement | Remove metal impurities and bran from wheat to improve flour fineness | Precision grading of flour for handmade bread to avoid clumping | Separate catalyst particles from corrosive liquids |

| Solution | Combination of stainless steel vibrating screen and magnetic separator, equipped with 120 mesh screen and dust removal system | Electric press type stainless steel screen (100 mesh) with foldable design | Full 316L stainless steel filter screen |

| Results | Impurity removal rate>99%, production efficiency increased by 40% | dough fluffiness increased by 25% customer repurchase rate increased by 30% | filtration accuracy reached 0.05mm, equipment life extended by 2 years |

Why choose us?

Mature technology: Advanced technologies such as vibrating screen, ultrasonic anti blocking, and air selection and grading are adopted to ensure screening efficiency and accuracy.

Flexible customization: The number of mesh layers, mesh size, material (304/316 stainless steel), and processing capacity can be adjusted as needed.

Successful case: We have provided screening equipment for multiple sesame oil factories and food processing enterprises, helping customers improve production efficiency and product quality.

-

Wheat flour sifter is used for sifting wheat flour to remove all kind of bugs and other unwanted part ...

-

Commercial flour sifter can remove lumps, foreign matter and contaminants in commercial flour, and is ...

-

Used in bakeries and food processing plants of all sizes to remove contaminants and lumps in flour...

-

How much is a wheat flour sifter

Flour is a food material and generally requires high sanitary conditions. Therefore, Dahan recommends ...

-

Flour Sifter Industrial for Sieving Flour

The purpose of flour sifting is mainly to remove impurities and sieve loose, so for different purposes ...

-

What are the advantages of commercial flour sifter?

Commercial flour sifter is a specially designed screening equipment for flour-based materials, which ...

-

How is the flour sifter used in the flour production process?

The processing accuracy of flour is mainly measured by the bran star content of flour. The whiter...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.