Gypsum powder Vibrating Screen

The function of a Gypsum powder Vibrating Screen is to remove impurities, classify, and control the particle size of gypsum powder, ensuring consistent product quality. Gypsum powder is a white, fine powder that is lightweight, prone to static electricity, and easily clumps, with poor flowability. However, it is safe and non-toxic during normal use and sieving. Its low hardness and abrasiveness result in minimal wear on the screen and equipment. This equipment can process approximately 0.2 to 5 tons of gypsum powder per hour, with the capacity adjustable depending on the machine size. The sieving particle size range is between 80 and 600 mesh, meeting the particle size requirements of various applications. The screen typically has 1 to 3 layers, simultaneously performing coarse separation, fine separation, and impurity removal. The parts in contact with the material are made of 304 stainless steel, which is rust-resistant, prevents powder leakage, and is easy to clean, meeting the hygiene and durability requirements of gypsum powder production.

The Sieving Process of Gypsum Powder Vibrating Screen

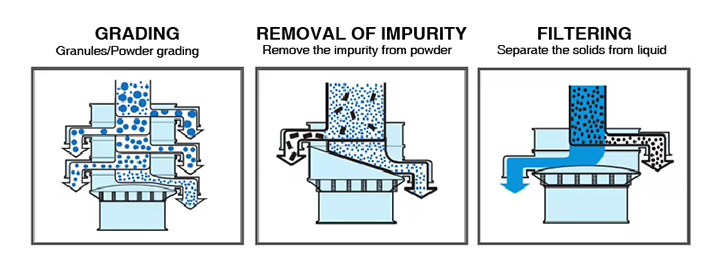

The sieving process of the Gypsum powder vibrating screen combines mechanical vibration and ultrasonic technology to quickly separate gypsum powder. After the equipment starts, the vibrating motor drives the screen surface to perform three-dimensional movements—horizontal, vertical, and inclined—allowing the gypsum powder to jump and diffuse on it, easily passing through the screen openings. However, because fine gypsum powder easily sticks to the screen or causes blockage, the equipment adds ultrasonic transducers to the screen. High-frequency, low-amplitude ultrasonic waves keep the powder particles suspended on the screen surface, reducing friction and breaking the static electricity and tension on the powder surface, allowing the powder to pass through the screen more smoothly. During the sieving process, large particles or impurities slide along the screen surface to the discharge port, while fine powder falls quickly with the help of ultrasonic vibration, completing the classification.

What are the functions of the Gypsum powder vibrating screen?

The function of the Gypsum powder vibrating screen can be said to be to make the powder more uniform and easier to use when processing gypsum powder. Gypsum powder is loose and lightweight, making it easy to flow when piled up, but prone to clumping when damp, and sometimes even sticking together due to static electricity. A vibrating screen separates these clumps of powder through vibration, allowing each particle to fall freely and contact the screen. The equipment can use different mesh sizes for multi-stage grading. For example, a 40-80 mesh screen is used in the coarse sieving stage to filter out large impurities, fibrous clumps, or uncrushed gypsum particles; the fine sieving stage uses 100, 200, or even 325 mesh or larger screens to separate the powder into different particle size grades. This allows for the use of very fine gypsum powder in the production of high-end ceramic molds, while coarser powder can be used for building plastering. Through this layered sieving, the originally loose and irregularly shaped gypsum powder is organized into a uniform particle size that meets the requirements for use, making subsequent processing easier.

Gypsum Powder Vibrating Screen Particle Size Chart

| Mesh (Mesh) | Particle Size Range (µm) | Applications |

| 80 mesh | 180–212 | Coarse powder, for hardness adjustment and construction |

| 100 mesh | 150–180 | Coarse powder, for engineering with low requirements |

| 200 mesh | 74–90 | Gypsum powder for construction, plastering, gypsum board |

| 250 mesh | 60–74 | Fine powder for construction, to improve flatness |

| 325 mesh | 45–60 | High-quality architectural gypsum powder, smooth and fine |

| 400 mesh | 37–45 | Industrial or rapid-setting applications |

| 500 mesh | 25–30 | Ultra-fine powder, for fine filling or chemical industry |

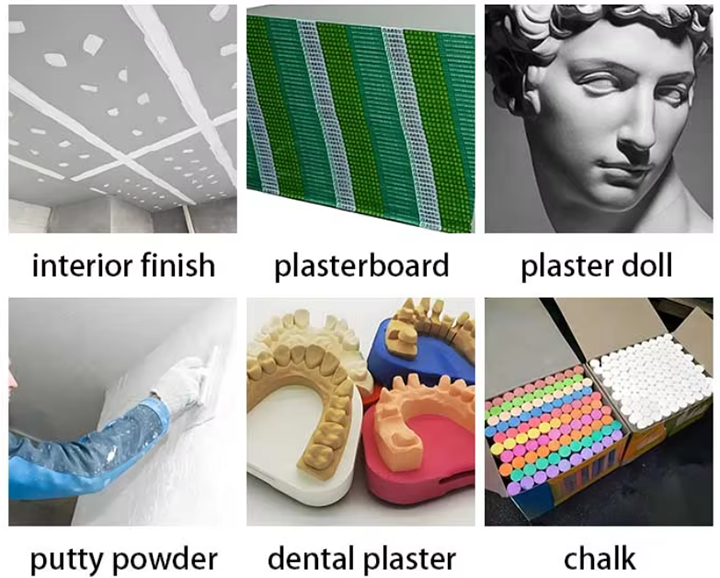

Gypsum Powder Vibrating Screen Applications

Gypsum powder vibrating screens cover many applications of gypsum powder. In the construction industry, gypsum powder is used to make gypsum board, gypsum blocks, joint compound, and adhesive plaster. The vibrating screen can sift the powder into a fine and uniform consistency, making construction easier and ensuring stable strength after solidification. In ceramics and arts and crafts, gypsum powder is used to make grouting molds. The finer and more uniform the powder, the better the water absorption and surface smoothness of the mold. The vibrating screen can effectively manage the powder. In pharmaceuticals and food, gypsum powder is used in traditional Chinese medicine formulas or calcium supplements. High requirements are placed on equipment hygiene and materials. The all-stainless steel structure and easy-to-clean design of the vibrating screen are well-suited for handling this high-purity powder.

Gypsum Powder Vibrating Screen Application Cases

Gypsum powder vibrating screens have numerous applications in actual production. At a building materials factory, when using ordinary vibrating screens to sieve gypsum powder, the screens frequently clogged due to the moisture content of the raw material and the requirement to sieve to a fineness of 150 mesh or higher. This necessitated shutdowns for cleaning every two hours, impacting production efficiency. After switching to an ultrasonic vibrating screen equipped with a 37kHz ultrasonic transducer and a three-layer stainless steel screen (upper layer for impurity removal, middle layer for grading, and bottom layer for finished product), the problem was resolved. On-site, gypsum powder that previously easily stuck to the screen now passed smoothly under ultrasonic vibration. The equipment can operate continuously for 24 hours, increasing output by approximately 40%, while the finished powder fineness compliance rate remains stable at around 99%. The entire production process is more stable, and powder handling is smoother.

The Gypsum powder vibrating screen utilizes ultrasonic technology to solve the clogging and screen sticking problems commonly encountered by traditional sieving equipment when handling fine, sticky, and statically charged gypsum powder, allowing the powder to pass through the screen smoothly. Based on an understanding of the safety and physical properties of gypsum powder, the equipment can maintain a high hourly processing capacity while performing various processes, from coarse sieving to fine grading. In the construction, ceramics, or pharmaceutical industries, as long as the mesh size and number of layers of the sieve are selected correctly, the gypsum powder can proceed to the next stage of production in a suitable state. In practical applications, such as in large building materials plants, it has been shown that continuous operation of the equipment significantly increases output, and the fineness of the finished powder remains stable.

-

Double deck with incline vibrating screen

Double deck with incline vibrating screen adopts high-quality wear-resistant screen mesh and high-strength steel structure.

-

Liquid vibratory sifter is a device used to separate solid particles from liquid.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Raw sesame is often mixed with soil, sand, metal chips, glass fragments, etc. These impurities not only affect the taste.

-

Feldspar powder Vibrating Screen

Feldspar powder vibrating screen continuously agitates and shakes the feldspar powder on the screen, breaking up clumps and...

-

Phosphate rock powder Vibrating Screen

Phosphate rock powder Vibrating Screens are screening devices designed to utilize the characteristics of phosphate rock powder...

-

Cement clinker Vibrating Screen

The Cement clinker vibrating screen is used in the screening of cement clinker, offering a wide range of processing capacities...

-

Wood Chip Vibrating Screen

Wood Chip Vibrating Screen separates wood chips of different sizes while removing impurities such as stones, twigs, and fragments...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.