Semsam Seed Sieve

![[field:title/]](/uploads/250731/1-250I11GI0H0.jpg)

Callback

| Mesh size: | 2-500 mesh |

| Capacity: | 100-3300kg/h |

| Number of layers: | 1-6 layers |

Made of food-grade stainless steel (such as 304 material), corrosion-resistant and rust-proof

organic impurity removal rate can reach 95%, and inorganic impurity removal rate can reach 98%

2-6 different gradings can be achieved

What is Semsam Seed Sieve

Raw sesame seeds often contain impurities such as soil, sand, metal fragments, and glass shards. These impurities not only affect the taste but may also harm human health. Semsam Seed Sieve can effectively remove these impurities, ensuring the food safety of sesame products. The product sieve mesh range is 20-400 mesh, with a production capacity of 200-500 kg/h for small-scale production, 500-1000 kg/h for medium-scale production, and 1000-3500 kg/h for large-scale production.

Sesame seed sieves are primarily categorized into circular vibrating screens, linear vibrating screens, and ultrasonic vibrating screens, each with its own unique advantages. Circular vibrating screens are suitable for fine screening and handling a variety of materials; linear vibrating screens excel at high throughput and screening accuracy, making them suitable for continuous, large-scale sesame grading; and ultrasonic vibrating screens, based on traditional vibrating screens, effectively solve the common problem of screen clogging in sesame powder screening by using ultrasonic waves, significantly improving the screening accuracy and pass rate of fine powders.

What are the types of Semsam Seed Sieve?

Sesame seed sieves are primarily used for screening and grading sesame seeds. Based on their operating principles and structural features, common types include circular vibrating screens, linear vibrating screens, and ultrasonic vibrating screens. The following describes these three types of sieves in terms of their characteristics and parameters.

When screening sesame seeds, the circular vibrating screen causes the material to move three-dimensionally on the screen surface, spreading the sesame seeds out and ensuring full contact with the screen mesh, thus separating impurities and broken particles. It can perform both dry and wet screening, making it ideal for processing sesame seeds. The ring-shaped clamp allows for quick screen replacement without interrupting work. The machine has a small footprint, making it easy to integrate into the production line. It operates stably with low noise, and daily maintenance is simple. Screens can be made with 1 to 5 layers, made of stainless steel or carbon steel, with mesh sizes ranging from 2 to 500 mesh. Power ranges from 0.75 to 4 kilowatts, and it can process 50 kilograms to 10 tons of sesame seeds per hour.

When screening sesame seeds, the linear vibrating screen causes the material to move in a straight line along the screen surface, covering a relatively long path, making it suitable for batch and continuous operations. The sesame seeds move evenly on the screen surface, separating particles of different sizes and reducing mixing. The equipment has a simple structure, is easy to maintain, and has a low probability of malfunction. The entire structure is sealed, preventing dust from easily escaping during operation. Screen widths range from 0.5 to 2 meters, lengths from 1 to 5 meters, and materials include stainless steel or high-manganese steel, with mesh sizes from 2 to 300 mesh, power from 1.5 to 11 kilowatts, and a processing capacity of 2 to 20 tons of sesame seeds per hour.

An ultrasonic vibrating screen adds an ultrasonic device to a regular vibrating screen, reducing screen clogging when sieving sesame seeds. The subtle vibrations break up clumped, clump-like sesame seeds and impurities, allowing them to pass smoothly through the screen openings. Reduced friction between the sesame seeds and the screen extends the screen's lifespan. This equipment offers screen mesh sizes between 80 and 600 mesh, reaching the micron level, making it suitable for fine material sieving. Powered by an ultrasonic power supply ranging from 50W to 1000W, it can sieve even lightweight, moisture-absorbing, clumping, and statically charged sesame seeds more thoroughly.

What are the advantages of the Semsam Seed Sieve?

The Semsam Seed Sieve removes sand, dirt, weed seeds, and bad seeds from sesame seeds, and separates sesame seeds of different sizes, resulting in cleaner and more uniform sesame seeds. Clean and uniform sesame seeds produce better-tasting and more appealing products, whether for oil extraction, paste making, or roasting; the oil is clearer, the paste is smoother, and there's less chance of some seeds burning during roasting. The sifted sesame seeds also facilitate smoother subsequent processes like washing, drying, and grinding, reducing machine clogging and ensuring more stable processing without repeated handling. This makes it suitable for small workshops or production lines.

Semsam Seed Sieve model parameters

|

Model |

Dimensions (mm) |

Power |

Number of screen layers |

Screen specifications (commonly used) |

Production capacity |

|

XZS-400 |

φ400×600 |

0.18kW |

Single/double layer |

0.5mm, 0.8mm |

100–300kg/h |

|

XZS-600 |

φ600×800 |

0.25kW |

Single/three layers |

0.4–1.2mm replaceable |

200–500kg/h |

|

XZS-800 |

φ800×950 |

0.55kW |

Multi-layer |

Multi-mesh combination |

500–800kg/h |

What is the working principle of semsam Seed Sieve?

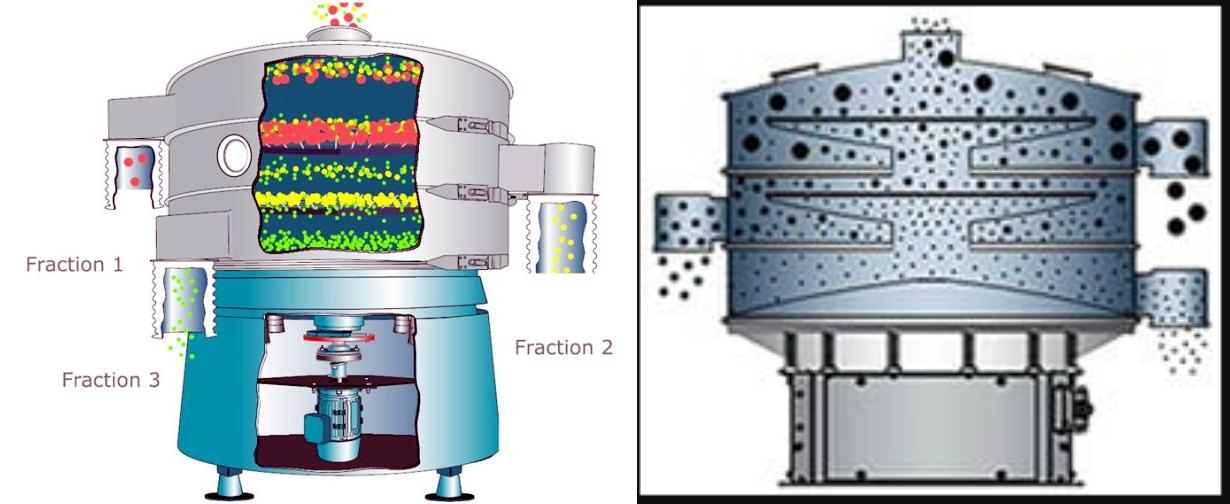

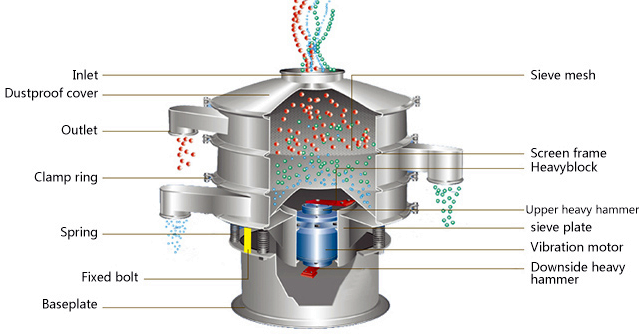

Semsam seed sieves use vibration to grade sesame seeds and remove impurities. Whether it's a round, linear, or ultrasonic vibrating sieve, the principle is similar: different vibration methods make the sesame seeds on the sieve surface move, achieving separation. The vibrating motor or exciter inside the machine generates high-frequency, low-amplitude vibrations, causing the sieve box and screen to vibrate together. The sesame seeds jump and roll continuously on the sieve surface, reducing friction between the particles and with the screen, naturally causing them to separate into layers. The screen has small holes of a fixed size, allowing small broken sesame seeds, dust, and dirt to pass through and fall down, while fuller sesame seeds, large stones, and grass seeds remain on the screen and move forward. Many sesame sieves have multiple layers of screens, each with a different aperture size. The upper layer removes large impurities, and the lower layer removes finer impurities, filtering the sesame seeds layer by layer.

What are the structural features of a semsam Seed Sieve?

The Semsam Seed Sieve consists of a sieve box, a vibrating device, and sieve mesh. The sieve box frame is welded from steel, providing stable support for the entire device. The sieve mesh is typically made of stainless steel wire mesh or perforated plate, with the mesh size customized according to the sesame seed size and actual sieving requirements. Support springs or shock absorbers are installed below the sieve frame to support the sieve body and reduce the impact of vibration on the ground. The vibrating device contains a vibrating motor and an eccentric block, generating vibration during operation that causes the sesame seeds to bounce and move on the sieve mesh, separating sesame seeds of different sizes from impurities. The equipment also features a feed inlet, a qualified sesame seed outlet, and an impurity outlet for convenient material handling.

Recommended mesh number of semsam Seed Sieve

|

Screening purpose |

Recommended sieve hole (mm) |

Corresponding mesh number (approximate) |

|

Removal of large impurities (straw, stones) |

>2.0mm |

<8 mesh |

|

Removal of small seeds, broken seeds |

1.0–1.4mm |

14–18 mesh |

|

Removal of dust, fine impurities |

<0.85mm |

>20 mesh |

|

Selected particle size classification |

1.6mm upper sieve + 1.2mm lower sieve |

12 mesh-16 mesh combination |

The role of semsam Seed Sieve in sesame screening process

During sesame processing, raw sesame seeds often contain impurities such as sand, straw, pebbles, unripe seeds, broken sesame seeds, and light sesame husks. If these impurities aren't removed before roasting or pressing, the taste and quality of the sesame oil will deteriorate, and it can also damage the machinery or clog equipment. Semsam Seed Sieve effectively separates these impurities, removing everything from large pieces of straw and soil to fine sand, barely visible colored particles, and metallic impurities. Multiple sieving processes result in cleaner, purer sesame seeds, leading to a better-tasting and safer product, and improving overall quality and appearance.

What can semsam Seed Sieve be used for?

Semsam Seed Sieve can be used in homes or small oil mills to clean and grade sesame seeds, preparing them for oil extraction. It removes impurities, resulting in cleaner sesame seeds and protecting the oil press, leading to higher quality oil. Whether pressing sesame oil or preparing to fry sesame seeds, it can be used first. The fine, even mesh allows small impurities like fine sand, straw, and seed shells to pass through with a manual or electric shake, leaving the plump sesame seeds on top. After processing, the impurity content of the sesame seeds can be reduced from 2.3% to below 0.1%, resulting in smoother oil extraction and improved taste and quality of the finished product.

Material application examples of semsam seed sieve

Before sesame oil pressing or frying, sesame seeds usually need to be sieved to remove impurities such as fine sand, straw, and seed shell fragments. As the core tool in this step, the Semsam seed sieve is equipped with a fine and uniform screen. Through manual or electric vibration, the sesame seeds are moved in layers on the screen surface, small particles or debris fall from the screen holes, and the complete sesame seeds remain on the screen surface to achieve primary screening.

Taking a family oil press as an example, 500 grams of raw sesame seeds are pre-screened with a matching stainless steel seed screen. The screening process lasts about 2-3 minutes and can remove about 2% of fine impurities and broken seeds. This step significantly reduces the residue blockage during the oil pressing process and avoids the wear of the oil pressing screw by gravel. At the same time, the surface of the sieved sesame seeds is cleaner, the frying process is more uniform, and the oil yield and oil quality are improved.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Swing Vibrating Screen is a high-precision fine-particle screening equipment, also known as a reciprocating vibrating screen.

-

Grading vibrating sieve is a mechanical device that uses the principle of vibration to screen and grade materials of different particle sizes.

-

Dry Material Silica Powder Screening Machine

The dry material silicon powder screening machine is a vibrating screen device used for efficient screening and grading of dry silicon powder...

-

Screening Equipment DH-1000-2S

Screening equipment DH-1000-2S is a circular vibrating screening equipment with a diameter of 1000mm and two discharge ports...

-

Large vibrating screen equipment manufacturers

Xinxiang Dahan Machinery is a large-scale manufacturer specializing in the manufacture of vibrating screen equipment...

-

Tumbler Screening Machines

Tumbler Screening Machines are available in carbon steel, stainless steel, and special steel to meet...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.