Hemp core powder vibrating screen

![[field:title/]](/uploads/250509/6-2505091J24U92.png)

Callback

Hemp core powder vibrating screen is a device used to screen and separate fine particles such as hemp core powder. It moves the material on the screen surface by vibration to achieve the purpose of classification.

Screen specifications: 10-800 mesh

Output: 100-2000kg/h

Power: 0.25-3kw

What is hemp core powder vibrating screen?

Hemp core powder refers to the powder of the medullary part extracted from the stem of hemp plants (such as hemp, flax, etc.). The stem of hemp plants consists of the outer bast fiber and the inner core pith. Hemp core refers to this part of the soft and porous internal tissue. After extracting the bast fiber, the remaining stem part is processed (such as crushing, drying, etc.) to obtain hemp core powder.

Hemp core powder vibrating screen is an industrial equipment specially used for separating and screening hemp core powder. Its core working principle is to use the exciting force generated by the vibration motor to make the hemp core powder jump on multiple layers of sieves with different mesh sizes, so as to achieve accurate classification of powders of different particle sizes.

Common hemp core powder vibrating screens can be equipped with multiple layers of sieves. For example, a 20-mesh coarse screen is used to remove larger impurities, a 40-mesh and 80-mesh medium screen is used to separate powders of different coarseness and fineness, and a fine screen above 100 mesh is used to obtain finer hemp core powder. By selecting the appropriate number of screen layers and sieve hole size (mesh number), the hemp core powder can be efficiently separated into the required particle size range to meet the needs of different application scenarios, such as industrial raw materials, animal feed additives, etc.

Function of hemp core powder vibrating screen

Hemp core powder vibrating screen is a mechanical equipment that uses the principle of vibration to separate and screen hemp core powder. Its main function is to classify and purify hemp core powder according to particle size to meet the needs of subsequent processing or application.

① For specific materials: This vibrating screen is specially used to process the powdered material obtained after the hemp core (usually the inner medullary part of the stem of a plant such as hemp or flax) is processed.

②Use vibration: The equipment generates vibration through a vibration motor or other excitation device, so that the hemp core powder jumps and moves on the screen surface.

③Achieve separation: Screens of different specifications are set on the screen surface. By controlling the aperture size of the screen, hemp core powders of different particle sizes can be separated, impurities, coarse particles or fine powders can be removed, and products with the required particle size range can be obtained.

Types of vibrating screens suitable for hemp core powder

According to the characteristics of hemp core powder, the following types of vibrating screens are more commonly used:

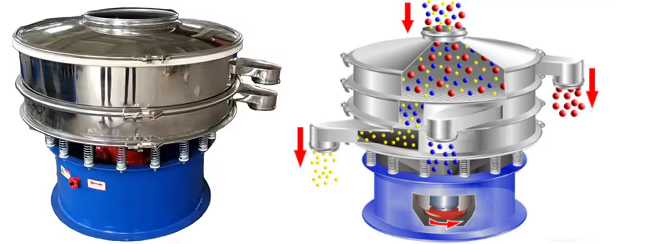

1.Rotary vibrating screen (circular vibrating screen)

Applicable situations: Used when the hemp core powder has a finer particle size and good powder fluidity

Features: Multi-layer screens can be used for multi-level classification; good sealing structure to prevent dust leakage; easy to clean and convenient to replace the net

Disadvantages: When encountering hemp core powder with strong fibrous properties, the screen may be blocked.

Processing capacity (kg/h): 100-5000

Screening mesh range: 20-500 mesh

2.Linear vibrating screen

Applicable situations: When the hemp core powder contains impurities of different particle sizes and needs to be quickly coarsely screened;

Features: Suitable for medium and coarse particle screening; large screening output; long screen surface, can achieve a large processing capacity;

Disadvantages: relatively poor sealing, dust collection device needs to be installed.

Processing capacity (kg/h): 500-20000

Screening mesh range: 10-200 mesh

3.Airflow screen

Applicable situations: fine powder screening is required, and hemp core powder is easy to fly;

Features: use negative pressure airflow + rotating blades for screening; high-efficiency fine screening, suitable for materials with particle size <200 mesh; fully sealed, excellent dustproof performance;

Disadvantages: small output, complex structure, suitable for processes with high powder precision requirements.

Processing capacity (kg/h): 50-1000

Screening mesh range: 100-800 mesh

4.Vibrating filter screen (bottom discharge type)

Applicable situations: Hemp core powder is used as impurity removal in liquid additives or slurry filtration;

Features: used for liquid-solid separation; fine screen, high filtration accuracy; suitable for screening of viscous liquid and powder mixture.

Processing capacity (kg/h): 200-5000

Screening mesh range: 20-400 mesh

Video of hemp core powder vibrating screen

Working principle of hemp core powder vibrating screen

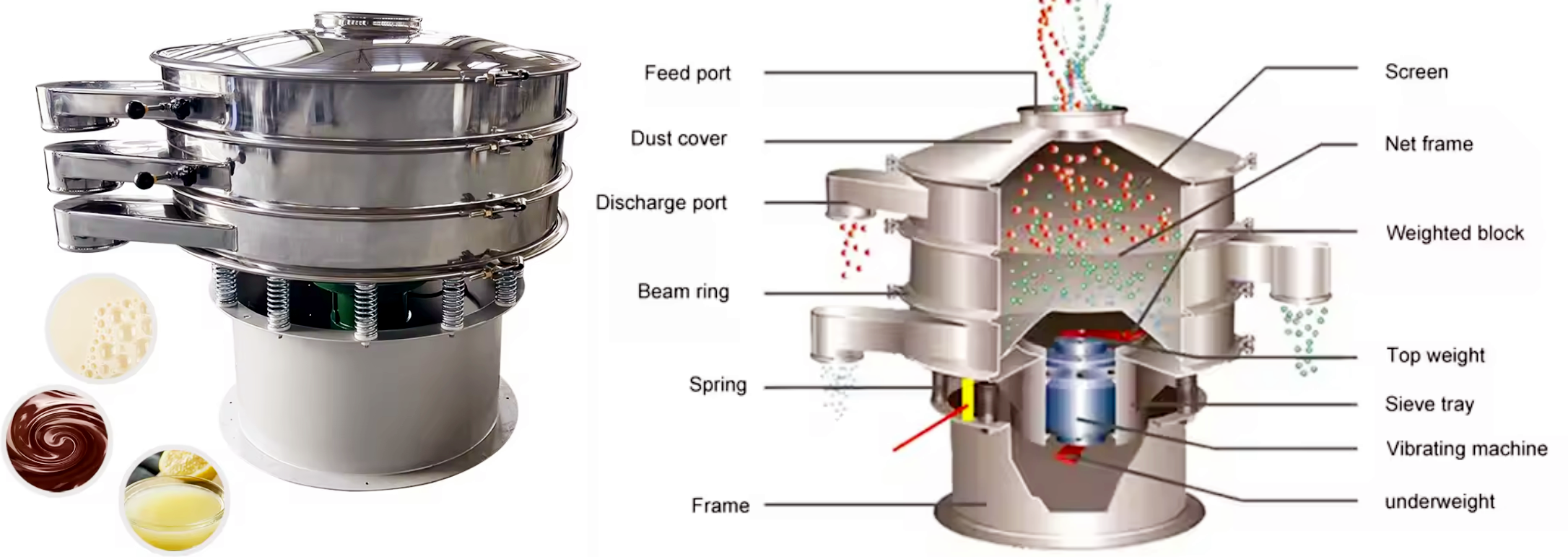

The hemp core powder vibrating screen usually adopts the working principle of the rotary vibrating screen, with a vertical vibrating motor as the excitation source. The eccentric weights at the upper and lower ends of the motor convert the rotational motion into horizontal, vertical, and inclined three-dimensional motion, and transmit it to the screen surface.

The hemp core powder enters the equipment through the feed port and moves up, down, left and right on the screen surface. According to different screening requirements, the material passes through 1-5 layers of screening layers with screens of different mesh sizes. The screen cleaning device under each layer of the screen continuously hits the screen, so that the material can be screened smoothly. The materials of different mesh sizes pass through the screens of the corresponding mesh sizes of each layer or are discharged through the discharge ports set at each layer, finally achieving the purpose of screening or filtering.

Structure of hemp core powder vibrating screen

Hemp core powder vibrating screen mostly adopts circular or linear vibrating screen. The structure may be slightly different according to different process requirements, but the basic structure usually includes the following parts:

Screen box: It is composed of upper cover, middle cylinder and lower bottom. Multiple layers of screen (1~3 layers) are set inside the screen box to achieve coarse and fine classification

Screen system: It adopts fine mesh stainless steel woven mesh (such as 60~200 mesh), which is suitable for the particle size range of hemp core powder

Vibration motor: It provides exciting force to make the screen body produce three-dimensional or linear vibration, thereby affecting the movement trajectory of the material

Base and shock absorption system: The whole machine is connected to the base through rubber springs or spiral springs, which plays a supporting and shock absorbing role

Discharge port and receiving device: It is usually equipped with multiple discharge ports for discharging coarse powder and fine powder after grading and screening

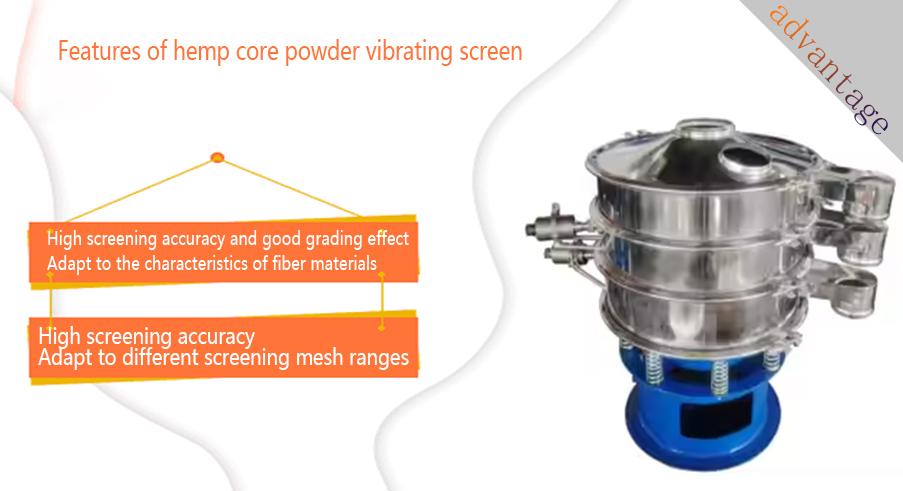

Features of hemp core powder vibrating screen

High screening accuracy and good grading effect: It can be configured with multiple layers of screens to achieve synchronous grading of 2~4 materials of different particle sizes. The screening particle size can be controlled within the range of 80~200 mesh, which is suitable for most fiber powder applications.

Adapt to the characteristics of fiber materials: In view of the characteristics of hemp core powder that it is light, easy to entangle and easy to fly, it is often equipped with an ultrasonic vibration device to solve the problem of fine powder sticking to the net and blocking the net, and improve the screening efficiency.

High screening accuracy: Through reasonable structural design and parameter adjustment, it can achieve accurate classification of hemp core powder and reduce the mixing of coarse particles in fine powder or fine powder in coarse particles.

Adapt to different screening mesh ranges: You can choose a combination of screens with different meshes according to specific application requirements, such as a combination from coarse screens (such as 20 meshes) to fine screens (such as 100 meshes or more).

Specifications of hemp core powder vibrating screen

|

Type No. |

DH-600 |

DH-800 |

DH-1000 |

DH-1200 |

DH-1500 |

DH-1800 |

DH-2000 |

|

Diameter mm |

Φ600 |

Φ800 |

Φ1000 |

Φ1200 |

Φ1500 |

Φ1800 |

Φ2000 |

|

Screen area m |

0.24 |

0.45 |

0.67 |

1.0 |

1.6 |

2.43 |

3.01 |

|

Screen specification (mesh) |

2-500 |

||||||

|

Feed particle size mm |

<Φ10 |

<Φ15 |

<Φ20 |

<Φ30 |

<Φ30 |

<Φ30 |

<Φ30 |

|

Vibration times rpm |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Effective screen surface diameter mm |

Φ560 |

Φ760 |

Φ930 |

Φ1130 |

Φ1430 |

Φ1760 |

Φ1960 |

|

1-5 |

|||||||

|

Power Kw |

0.25 |

0.55 |

0.75 |

1.1 |

1.5 |

2.2 |

3 |

Application of hemp core powder vibrating screen

Papermaking industry: Hemp core powder is one of the important raw materials for papermaking. Vibrating screen can be used to screen hemp core powder, remove impurities and unqualified particles, and improve the quality and performance of paper.

Textile industry: In the processing of hemp fiber, hemp core powder vibrating screen can be used to grade and screen hemp core powder, providing raw materials that meet the requirements for subsequent textile processes.

Chemical industry: Hemp core powder can be used as an additive or raw material for certain chemical products. Vibrating screen can accurately screen it to ensure the quality and stability of chemical products.

Other fields: It can also be applied to the pharmaceutical, food, building materials and other industries to screen and grade similar powdered materials.

Hemp core powder vibrating screen manufacturer

Dahan Machinery is a well-known manufacturer of vibration screening equipment and has a certain reputation in China. They produce various types of vibrating screens, including circular vibrating screens, linear vibrating screens, rotary vibrating screens, etc. These equipment are widely used in chemical, food, pharmaceutical, mining and other industries. If you are interested in Dahan Machinery's hemp core powder vibrating screen, I suggest you contact them directly to get more detailed and accurate information, such as:

What is the purpose of the hemp core powder you need to screen? (For example: industrial use, edible, etc.)

What particle size range of hemp core powder do you want to screen out?

What are your requirements for the output of the vibrating screen?

Do you have special requirements for the material, number of layers, etc. of the vibrating screen?

Do you want to know the type of equipment, manufacturer information, price or other aspects?

With more specific information, we can better provide you with relevant knowledge and suggestions.

-

Millet vibrating sieve is widely used in millet processing industry, including millet processing plants, rice flour plants, rice......

-

Vibro Sifterfor Powdered Sugar

Powdered sugar vibro sifter is a device for screening sugar powder. It uses vibration to divide sugar

-

Powder Coating Ultrasonic Sieving Machine

The screening accuracy can be increased by 1-70%, and the output can be increased......

-

Screening machine is a mechanical equipment that uses physical separation technology to classify, remove impurities or accurately sort granular, powdery or block materials.

-

Tea sieving machine is a kind of equipment specially used for grading, removing impurities and sieving tea leaves, which is commonly used in tea processing, packaging and other links. The equipment can separate tea leaves of different specifications through multiple layers of screens......

-

How to Apply Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine is a fine powder sieving machine with relatively perfect te ...

-

Sunflower seeds screening machine

Sunflower seed screening machine, also known as sunflower seed vibrating screen or separator, is a special equipment ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration ...

-

Sweet potato powder screening machine

The Sweet potato powder screening machine effectively screens, filters and removes sweet potato starch to ensure the quality ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.