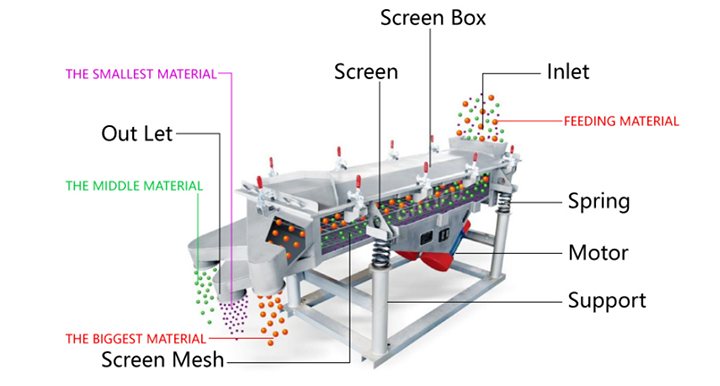

Wood Chip Vibrating Screen

Wood Chip Vibrating Screen separates wood chips of different sizes while removing impurities such as stones, twigs, and fragments. This results in a more uniform and consistent size of the raw material before it enters the next processing stage, facilitating the production of engineered wood products, biomass fuel, or wood flour. The machine boasts a robust and stable structure, with the main frame typically constructed from Q235 carbon steel or Q345B manganese steel, making it resistant to deformation during daily use.

The Wood Chip Vibrating Screen's screen box and mesh, which come into contact with the material, can be made of 304 or 316 stainless steel, offering good wear resistance. The equipment's processing capacity ranges from 0.12 tons to 20 tons per hour, adjustable to suit specific production needs. It supports 1 to 6 screening layers, capable of separating 2 to 7 different wood chip sizes at once. Mesh apertures are available from 0.5 to 20 mm, with common sizes including 500×2000mm, 1000×2000mm, and 1500×2500mm, but custom sizes are also available to suit site conditions.

Wood Chip Vibrating Screen Configuration

The Wood Chip Vibrating Screen is designed for ease of use and optimal screening performance. Common screen types include woven metal wire mesh and polyurethane mesh. Manganese steel woven wire mesh is robust and wear-resistant, suitable for screening larger wood chips and also separating impurities. Polyurethane mesh offers good elasticity, is less prone to clogging, and is better suited for wood flour or finer materials. Nylon mesh can be selected for applications with higher screening requirements. Screen sizes can be matched to the equipment model; for example, 0.5×2.5 meters for the 525 model, 1×3 meters for the 1030 model, and 1.2×4 meters for the 1240 model. The screen features a quick-release structure and a tensioning device, making adjustments and replacements very time-saving, typically completed within minutes. The equipment also includes rubber spring shock absorbers and a bouncing ball device to reduce clogging.

Features of the Wood Chip Vibrating Screen

The Wood Chip Vibrating Screen is driven by dual motors, creating linear vibration during operation. Wood chips continuously bounce forward on the screen surface, making it easier for them to pass through the screen holes and resulting in cleaner separation of fine particles. Overall power consumption is relatively controllable, yet the processing capacity of a single unit is considerable, handling a significant amount of wood chips per hour, making it suitable for continuous production lines. The equipment supports multi-layer screen combinations, with 1 to 6 layers available as needed, separating wood chips of different sizes in one pass. The screen hole size and vibration frequency can also be adjusted, eliminating the need for major structural modifications when changing raw materials. The entire machine features a closed structure, preventing dust from escaping and creating a cleaner production environment. The rubber springs act as a buffer, significantly reducing vibration and noise during operation, minimizing impact on the surrounding environment. Routine maintenance is also relatively simple. The screen frame has a quick-release structure, requiring no complicated tools for screen replacement or inspection, resulting in short downtime and making it more suitable for long-term use.

Wood Chip Vibrating Screen Application Cases

The Wood Chip Vibrating Screen has practical applications in various wood chip processing scenarios. For example, at a biomass fuel production base, the equipment is equipped with a 1.5kW vibrating motor and uses two layers of manganese steel woven screens with 10mm and 2mm mesh openings respectively. After operation, it can process approximately 15 tons of wood chips per hour. Larger wood chips are directly sent to make biomass pellets, while finer particles are used for wood flour processing, resulting in clearer raw material allocation and reduced waste. In another engineered wood processing plant, a linear vibrating screen made entirely of 304 stainless steel and equipped with three layers of polyurethane screens was selected to separate wood chips by size for use in the production of boards of different thicknesses. This solves the problem of uneven particle size in traditional manual screening, resulting in more stable material dimensions.

Applications of Wood Chip Vibrating Screens

Wood chip vibrating screens can be used in wood chip plants, wood pellet plants, paper mills, engineered wood products plants, and biomass power plants. The choice of equipment varies depending on the scale of production. Small and medium-sized processing plants typically use lightweight linear vibrating screens, which are compact, easy to adjust, and operate under low daily pressure. Large production lines, on the other hand, choose heavy-duty linear vibrating screens with more powerful vibrating motors to handle larger feed volumes. In terms of usage, if only impurities are to be removed from the wood chips, a single screen is sufficient; to separate the wood chips into three or four sizes, four or five screen boxes can be installed. The feed inlet can be directly connected to a belt conveyor or screw conveyor, and the discharge outlet can be connected to a bucket elevator or pneumatic conveying duct, making it easy to integrate into the entire production line and reducing manual operation.

Wood chip vibrating screens are commonly found on many production lines due to their stable structure and long service life. During operation, the equipment separates wood chips of different sizes, reduces dust dispersion, and results in a neater-looking finished product with fewer impurities. Whether the screening requirements are fine or the on-site conditions are complex, it can maintain a relatively stable working state and solve problems such as inconsistent sawdust size and high impurity content. By selecting the appropriate model and screen, this type of equipment can adapt to different output and screening needs, and can also be smoothly connected with upstream and downstream conveying and packaging equipment to form a continuous production process, reduce manual operation, and make the entire sawdust processing process smoother.

-

Double deck with incline vibrating screen

Double deck with incline vibrating screen adopts high-quality wear-resistant screen mesh and high-strength steel structure.

-

Liquid vibratory sifter is a device used to separate solid particles from liquid.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Raw sesame is often mixed with soil, sand, metal chips, glass fragments, etc. These impurities not only affect the taste.

-

Activated Carbon Screening Machine

Activated Carbon Screening Machine is a commonly used screening device in activated carbon production...

-

Plastic powder Screening Machine

Plastic powder Screening Machine is used in plastic processing and powder handling to classify, remove impurities...

-

Soybean Vibrating Screen

Soybean Vibrating Screens are widely used in soybean processing...

-

Iron ore powder Vibrating Screen

Iron ore powder Vibrating Screen uses two motors running synchronously in opposite directions to generate vibration, causing the screen surface to vibrate uniformly in a straight line...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.