Soybean Vibrating Screen

Soybean Vibrating Screens are widely used in soybean processing. They remove dust, bean stalks, and stones from soybeans and grade them by size, resulting in cleaner and easier-to-process raw materials. The equipment is driven by a vertical vibrating motor, which performs a combination of horizontal, vertical, and inclined vibrations, causing the soybeans to spread in a spiral motion on the screen surface. The screen mesh size can be selected according to particle size, suitable for soybeans of 0.5-1.5mm, with commonly used meshes of 13-35, and a mesh size error controlled within ±0.1mm. Screen sizes range from 400mm, 600mm, 800mm to 1800mm, with the basic model having a diameter of 330mm. Processing capacity is 500kg to 10t per hour, and it can operate continuously for 24 hours. One to five screen layers can be configured, but 1-3 layers are typically used to separate soybeans into several sizes at once, facilitating subsequent drying, pressing, or other processing.

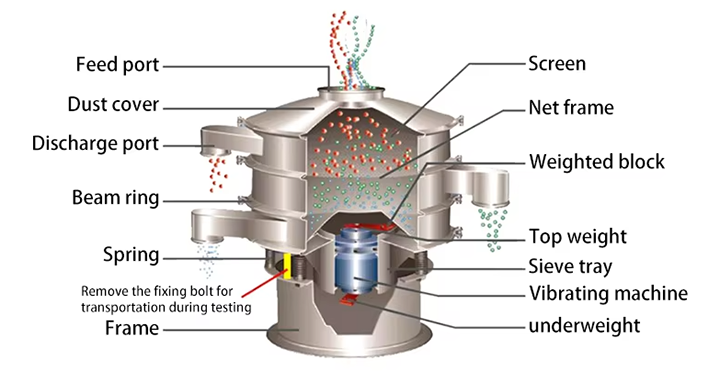

Soybean Vibrating Screen Configuration

The Soybean Vibrating Screen is configured with screening efficiency, material safety, and ease of operation in mind. The screen mesh is made of 304 stainless steel perforated plate or woven mesh, and the machine body in contact with the material is also made of 304 stainless steel, making it both wear-resistant and meeting food hygiene standards. The screen cleaning device features rubber bouncing balls that rapidly bounce and impact the screen, controlling the clogging rate to below 3%, preventing soybean fragments and skins from clogging the screen holes and ensuring smoother screening. The equipment also features a fully enclosed dust cover, with a transparent acrylic cover for easy observation of material movement within the screen, preventing dust and material spillage. The discharge port is equipped with an adjustable gate, allowing flexible control of the discharge speed and flow rate. Multiple discharge ports can be set to collect soybeans of different sizes separately, improving grading efficiency.

What are the functions of the Soybean Vibrating Screen?

The functions of the Soybean Vibrating Screen are designed around the characteristics of soybeans and processing requirements. First, it removes impurities. During harvesting, drying, or transportation, soybeans often become mixed with large impurities such as mud, stones, stems, leaves, and hemp rope, as well as small impurities such as fine sand and shriveled beans. Vibrating screens, using sieves with different mesh sizes, can remove these impurities, resulting in cleaner soybeans. Second, it grades soybeans. Before food processing or oil extraction, soybeans often need to be separated into large, medium, and small sizes. Graded soybeans are heated more evenly during crushing, pressing, or soaking, leading to smoother subsequent processing. Vibrating screens can also remove damaged and irregularly shaped beans. By adjusting the sieve holes and movement trajectory, broken, half-eaten, or insect-damaged beans are removed, ensuring that only whole soybeans remain. Additionally, in some processes, it can help dissipate heat or dry the material after sieving; vibration allows for greater air contact and faster heat exchange.

Soybean Vibrating Screen Types

Soybean vibrating screens can be categorized by material into all-stainless steel and semi-stainless steel types. The all-stainless steel model is entirely made of 304 stainless steel. The screen surface is polished, and the welded areas are ground smooth, making it rust-resistant, heat-resistant, and hygienic, suitable for food processing. However, it has higher material and processing costs, and installation requirements are more stringent. The semi-stainless steel model uses 304 stainless steel for the body and screen parts in contact with the material, while the base is made of Q235A carbon steel. Carbon steel bases have good plasticity and toughness, are easy to weld, and are less expensive than all-stainless steel, meeting the needs of ordinary screening. However, carbon steel is not corrosion-resistant and is prone to rusting in humid or dusty environments over time, and its hygienic conditions are not as good as the all-stainless steel model. The choice can be made based on the processing environment and budget.

Soybean Vibrating Screen parameters

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

|

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 | |

| DH-600 | 600 | 0.25 | 200 | ||||

| DH-800 | 800 | 0.55 | 500 | ||||

| DH-1000 | 1000 | 0.75 | 800 | ||||

| DH-1200 | 1200 | 1.1 | 1200 | ||||

| DH-1500 | 1500 | 1.5 | 1800 | ||||

| DH-1800 | 1800 | 2.2 | 2000 |

Soybean Vibrating Screen Application Scenarios

The Soybean Vibrating Screen can be used in some stages of soybean processing. In the raw material pretreatment stage, it can remove dirt, stones, and broken beans from the harvested soybeans and grade them by size, laying a foundation for subsequent processing. During the peeling and milling process, it separates broken soybean skins and kernels, resulting in purer soybean flour. In the oil extraction stage, it performs fine sieving, removing small impurities without affecting oil yield or quality. The soybean meal after oil extraction can also be sieved out with a vibrating screen to remove broken skins and dust, making it cleaner and more uniform for use as animal feed. In soybean product processing, such as tofu and soy milk production, it can grade soybeans by particle size, ensuring consistent raw material quality and more stable product texture.

As a screening device for soybean processing, the Soybean Vibrating Screen is widely used in many soybean processing plants due to its flexible configuration, excellent screening effect, and wide applicability. It employs a three-dimensional vibrating screening method, combined with adjustable screens, screen surface, and number of screen layers, to meet the screening needs of different stages of soybean processing, reducing soybean breakage and facilitating smoother screening. Available in both all-stainless steel and semi-stainless steel materials, it allows factories of different sizes and hygiene requirements to find a suitable model, balancing user experience and cost. The equipment's fully enclosed structure and easy-to-maintain design support continuous operation, helping factories reduce losses and improve production efficiency.

-

Double deck with incline vibrating screen

Double deck with incline vibrating screen adopts high-quality wear-resistant screen mesh and high-strength steel structure.

-

Liquid vibratory sifter is a device used to separate solid particles from liquid.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Raw sesame is often mixed with soil, sand, metal chips, glass fragments, etc. These impurities not only affect the taste.

-

Iron ore powder Vibrating Screen

Iron ore powder Vibrating Screen uses two motors running synchronously in opposite directions to generate vibration, causing the screen surface to vibrate uniformly in a straight line...

-

Coffee bean vibrating screen

A Coffee bean vibrating screen can effectively remove impurities from coffee beans or grade them to achieve a purer particle size, facilitating subsequent grinding and brewing...

-

Cocoa Powder Vibrating Screen

The Cocoa Powder Vibrating Screen is used to remove lumps and impurities from cocoa powder, and it can also classify and sieve according to particle size...

-

Sunflower seed vibrating screen

Sunflower seed vibrating screen are used for grading, removing impurities, and improving seed quality...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.