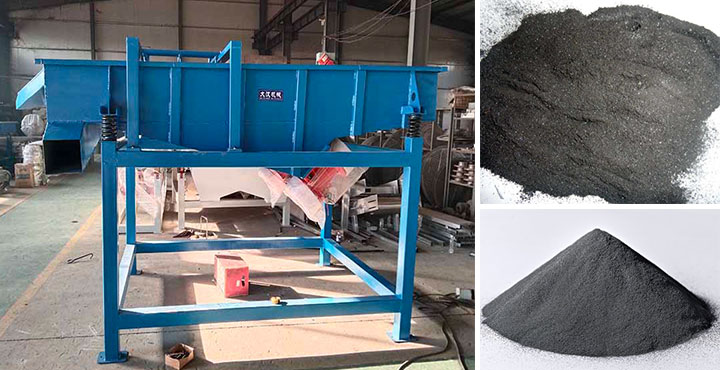

Iron ore powder Vibrating Screen

Iron ore powder Vibrating Screen uses two motors running synchronously in opposite directions to generate vibration, causing the screen surface to vibrate uniformly in a straight line. Because iron ore powder particles are fine and have a high specific gravity, they do not easily float. Qualified powder enters the screen surface and flows to the discharge port, while unqualified powder is discharged from below the screen. Common screen areas are 1.2×2.4m, 1.5×3.0m, and 2.0×4.0m; larger areas result in higher processing capacity, and can be selected according to production volumes of 5-80t/h. The screen surface inclination angle is controlled between 5° and 15° to ensure smooth powder movement. The screen aperture is determined according to the finished product particle size, commonly 0.15mm, 0.3mm, 0.6mm, and 1.2mm. Parts in contact with the material are mostly made of high manganese steel or 304/316 stainless steel, which are wear-resistant, impact-resistant, and corrosion-resistant, ensuring the equipment's service life and screening stability. Even with variations in iron powder particle size and moisture content, it can operate stably.

Iron Ore Powder Vibrating Screen Structure

An iron ore powder vibrating screen consists of a screen box, screen mesh, vibrating motor, vibration damping device, and support base. The screen box is the frame of the equipment, generally welded from steel plates, and contains a tensioning device to fix the screen mesh. The screen mesh directly contacts the iron ore powder; depending on the characteristics of the iron powder, woven or perforated mesh is commonly used, which is wear-resistant and sturdy. The vibrating motor is mounted on the side of the screen box and generates vibration force through high-speed rotation, causing the screen body to move. The vibration damping device is generally a rubber spring or composite spring, connecting the screen box and the base. It absorbs vibration, reduces impact on the ground, and lowers noise during machine operation. The base is used to fix the entire equipment, ensuring level stability during installation and smooth operation of the vibrating screen.

What are the benefits of an iron ore powder vibrating screen?

An iron ore powder vibrating screen offers many advantages when processing iron ore powder. Because iron ore powder particles are fine and have a high specific gravity, the linear reciprocating vibration of the screen surface allows the powder to fully contact the screen mesh, separating powders of different particle sizes, resulting in uniform particle size and stable quality in the finished product. The continuous vibration design allows for uninterrupted material feeding and screening, increasing output by approximately 30% compared to traditional screening equipment, making it more suitable for industrial production. The equipment operates smoothly, with a modular design reducing potential failure points. The vibrating motor provides uniform power output, minimizing iron powder jamming or polarization on the screen surface, resulting in fewer production interruptions. Operation and maintenance are simple; screen replacement and parts inspection are straightforward, requiring only basic training for ordinary operators. The limited number of wear parts facilitates easy purchase and replacement. The sealed housing controls dust, and the vibration damping device, combined with a low-noise motor, ensures stable operation even with slightly higher iron powder moisture content or variations in particle size, keeping noise levels within a reasonable range and minimizing environmental impact.

Iron Ore Powder Vibrating Screen Parameters

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Iron Ore Powder Vibrating Screen Application Cases

Iron ore powder vibrating screens have been widely used in iron ore powder processing. For example, a steel group's iron ore processing plant previously used screening equipment with low precision and efficiency, failing to meet the particle size requirements of high-end steel products. Later, several customized linear vibrating screens were introduced, equipped with screens of different aperture sizes, achieving three-stage fine screening. This increased processing capacity to 1.5 times the original capacity and screening accuracy from 85% to 98%, ensuring stable iron powder quality. Another small-to-medium-sized ore processing plant, whose iron ore powder had high moisture content and was prone to sticking and accumulating on the screen, used a wet linear vibrating screen with a sealed box and wear-resistant stainless steel screens. This not only solved the material blockage problem but also kept dust levels within acceptable limits. The equipment experienced fewer malfunctions during operation, and routine maintenance and parts replacement were simple, resulting in improved production efficiency and economic benefits.

Iron Ore Powder Vibrating Screen Applications

Iron ore powder vibrating screens have many uses in iron ore powder processing. For example, in the initial screening stage, they can screen coarsely ground iron ore powder mined from the mine, removing large impurities and substandard coarse powder, preparing it for subsequent fine processing. In the fine grading stage, iron powder can be separated into different particle size grades according to requirements, meeting the particle size requirements of industries such as metallurgy, chemicals, and building materials. In the impurity removal stage, it can separate out impurities such as mud and stones, making the iron powder purer. In addition, it is also suitable for screening finished products after further processing, or for performing particle size re-inspection before storage. It can be used in ore dressing plants, steel mills, and metallurgical processing plants to process large quantities of iron ore powder.

The Iron Ore Powder Vibrating Screen has a simple and robust structure, exhibiting good performance in screening accuracy, speed, and stability. The equipment can adjust parameters and materials according to production needs to cope with different working conditions. It is useful in various stages of iron ore powder screening, grading, and impurity removal. Many practical production cases show that this equipment can improve the quality and yield of finished iron ore powder, while making daily maintenance easier. Through continuous technology optimization and customized design, this equipment can better meet the production needs of different factories and provide support for iron ore powder processing.

-

Double deck with incline vibrating screen

Double deck with incline vibrating screen adopts high-quality wear-resistant screen mesh and high-strength steel structure.

-

Liquid vibratory sifter is a device used to separate solid particles from liquid.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Raw sesame is often mixed with soil, sand, metal chips, glass fragments, etc. These impurities not only affect the taste.

-

Coffee bean vibrating screen

A Coffee bean vibrating screen can effectively remove impurities from coffee beans or grade them to achieve a purer particle size, facilitating subsequent grinding and brewing...

-

Cocoa Powder Vibrating Screen

The Cocoa Powder Vibrating Screen is used to remove lumps and impurities from cocoa powder, and it can also classify and sieve according to particle size...

-

Sunflower seed vibrating screen

Sunflower seed vibrating screen are used for grading, removing impurities, and improving seed quality...

-

Peanut vibrating screen

Peanut vibrating screen remove impurities such as peanut stems, grade peanut kernels, and separate shelled kernels from the hulled kernels...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.