Liquid vibratory sifter

![[field:title/]](/uploads/260225/1-260225133T1250.jpg)

Callback

| Accuracy: | 5 microns |

| Filtration capacity: | 5 tons/hour |

| Motor power: | 0.25-3kw |

What is Liquid vibratory sifter?

Liquid vibratory sifter is a device used to separate solid particles from liquid. It uses mechanical vibration to move the solid particles in the liquid relative to the surface of the screen, thereby achieving solid-liquid separation. Filtration accuracy ranges from 0.025mm to 20mm, and the throughput depends on the material characteristics and machine model, typically ranging from 50 kg to over 5 tons per hour. The machine body is commonly made of 304/316L stainless steel or carbon steel with a corrosion-resistant lining. Corrosion protection options include PTFE lining, spraying, or rubber lining to meet the requirements of strong acid and alkali conditions.

The vibration force is adjusted via an eccentric block or electromagnetic drive, allowing independent setting of frequency and amplitude to match material flowability. It supports 24-hour continuous filtration. The screen structure can be flexibly configured as single-layer or multi-layer (commonly 1-3 layers) according to process requirements, enabling the grading, impurity removal, or solid-liquid separation of materials with multiple particle sizes in a single operation.

Video of Liquid vibratory sifter

What types of Liquid vibratory sifters are there?

Liquid vibratory sieves come in three common types: liquid filter sieves, edge-mounted rotary vibrating sieves, and high-frequency vibrating sieves. The choice between these three types depends on the specific needs of the liquid being sieved.

Liquid filter screens can filter liquids and separate solid impurities. They filter quickly, can separate solid particles of varying sizes, and are easy to clean and maintain, making them simple and user-friendly. They can be used in food processing to filter various liquids, in chemical production to remove impurities from raw materials, in pharmaceutical manufacturing to purify liquids, and in treating wastewater from production and daily life.

Side-mounted rotary vibrating screens use rotational vibration to separate materials. They separate particles of different sizes quickly, producing uniformly sized solid particles. Cleaning and routine maintenance are convenient, and operation is simple, requiring no complicated steps. This type of equipment can be used to screen various granular materials and grade them, especially in industries with precise particle size requirements.

High-frequency vibrating screens use high-frequency vibration to separate materials. They operate quickly, can handle small particles, produce clear results, operate smoothly, and have a compact size, requiring minimal space. This equipment is mainly used for screening and classifying fine particulate materials, and can separate fine materials according to specifications. It can be used in industries such as mining, metallurgy, and building materials.

How does Liquid vibratory sifter work?

During operation, the vibrator inside the liquid vibratory sifter generates high-frequency, low-amplitude vibrations. The liquid and suspended solids mixture is evenly distributed onto the screen from the inlet. Under continuous vibration, the liquid and fine particles rapidly pass through the screen openings, while larger solid particles are trapped. These trapped particles are propelled forward in a parabolic trajectory along the screen surface by the vibration, while the tilt angle of the screen assists in their transport to the outlet. Throughout the process, vibration not only promotes solid-liquid separation but also prevents screen clogging.

Advantages of Liquid vibratory sifter

The liquid vibratory sifter operates quietly, causing minimal noise impact on the surrounding environment during daily use. Its compact size makes it easy to place and move, enabling screening operations in various locations. During operation, the vibrator continuously agitates the material, ensuring it is evenly distributed and falls onto the screen, preventing accumulation. This type of sifter is suitable for processing small volumes of liquid materials with few impurities. It is simple and intuitive to operate, and its daily use and maintenance are relatively convenient.

Comparison of three types of equipment

| Equipment | Features | Scope of application |

|---|---|---|

| Liquid filter screen | Simple structure, high filtration accuracy | Liquid solid-liquid separation |

| Ring-type rotary vibrating screen | High screening efficiency, strong adaptability | Screening of powder and granular materials |

| High-frequency vibrating screen | High screening accuracy, suitable for ultrafine powder | Electronics, medicine, chemical industry and other industries |

Equipment Features Scope of application

Liquid filter screens have a simple structure, are easy to use, and can separate solid impurities from liquids with stable filtration results. Their simple construction allows for stable separation of fine particles, making them suitable for processing various liquid-solid mixtures. Ring-type rotary vibrating screens operate smoothly and screen materials thoroughly, suitable for both powdery and granular materials. High-frequency vibrating screens have a high vibration frequency and can screen very fine powders, making them ideal for processing fine materials in industries such as electronics, pharmaceuticals, and chemicals.

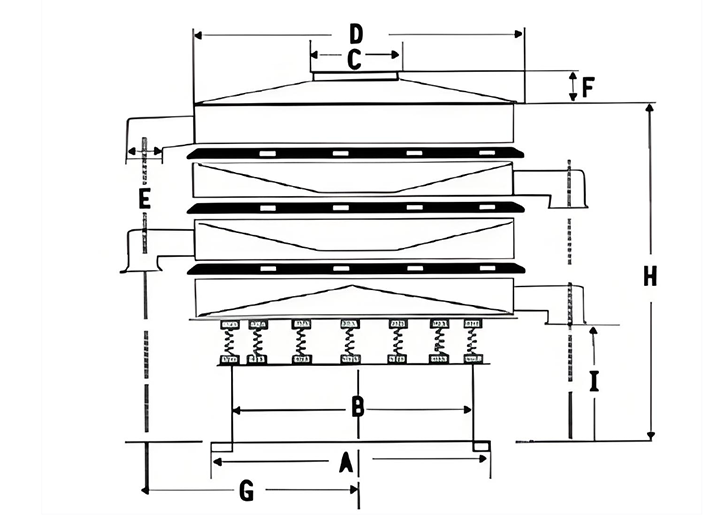

Structural composition of Liquid vibratory sifter

The liquid vibratory sifter is equipped with locking mechanisms to secure the equipment and ensure stable operation. The vibrating bucket receives and transports the liquid, and internally, it contains screens of different sizes to filter impurities from the liquid. Springs are installed around the equipment to cushion and absorb shocks, and a base and base cover support the machine body. Powered by a motor, all components work together to complete the screening process.

Technical parameters of Liquid vibratory sifter

| Model | DH-600 | DH-800 | DH-1000 | DH-1200 | DH-1500 | DH-1800 | DH-2000 |

|---|---|---|---|---|---|---|---|

| Diameter (mm) | Φ600 | Φ800 | Φ1000 | Φ1200 | Φ1500 | Φ1800 | Φ2000 |

| Screen area (m²) | 0.24 | 0.45 | 0.67 | 1.0 | 1.6 | 2.43 | 3.01 |

| Screen size (mesh) | 2-500 | 2-500 | 2-500 | 2-500 | 2-500 | 2-500 | 2-500 |

| Feed size (mm) | Φ10 | Φ15 | Φ20 | Φ30 | Φ30 | Φ30 | Φ30 |

| Vibration (rpm) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Effective screen surface diameter (mm) | Φ560 | Φ760 | Φ930 | Φ1130 | Φ1430 | Φ1760 | Φ1960 |

| Number of layers | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Power (kW) | 0.25 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 |

Application of liquid vibrating screen

Liquid vibratory sifters are commonly used in industrial production. In the food industry, they filter soy milk, refined starch, and purify liquid foods such as fruit juice, milk, and soy sauce, separating solid particles. In the pharmaceutical industry, they are used to purify traditional Chinese medicine liquids, improving their purity. In the chemical industry, they are frequently used to filter paints, resins, and other chemical liquids, separating and purifying solid particles to ensure product quality. In the ceramics industry, they are used to screen glazes, making the raw materials finer. In the mining and metallurgical industries, they are used for liquid-solid separation during ore leaching and tailings treatment, classifying mineral slurries and improving ore extraction efficiency. In paint and coating production, they remove particulate impurities, resulting in better gloss and quality in liquid products.

Liquid vibratory sifter dimensions

| Model | A | B | C | D | E | F | G | H | I |

|---|---|---|---|---|---|---|---|---|---|

| DH-1000-1S | 800 | 700 | 250 | 970 | 150 | 120 | 645 | 750 | 460 |

Price of Liquid vibratory sifter

The price of a liquid vibratory sifter typically ranges from $3,000 to $10,000. This price difference stems from the equipment's processing capacity, materials, and configuration. Small laboratory models cost approximately $2,000-$5,000, while large industrial-grade high-capacity models can exceed $9,000. If the material is corrosive or requires higher sieving precision, the use of special stainless steel or polyurethane screens and explosion-proof motors will increase costs, potentially raising the price by 30% to 50%. Furthermore, the level of automation control is also a contributing factor.

Liquid Vibratory Screening Solutions

For common water-soluble liquids, such as coolants and syrups, 304 stainless steel screens can be used, offering good strength and corrosion resistance. A standard single-layer or multi-layer vibrating screen is sufficient to meet production needs. If the liquid contains mild acids or alkalis, 316L stainless steel screens are recommended, as they offer superior corrosion resistance. Pairing them with a fully enclosed vibrating screen with enhanced sealing will prevent liquid evaporation and contamination. For high-viscosity liquids such as inks, wedge-shaped mesh or large-aperture metal mesh should be used to reduce screen clogging. High-frequency vibrating screens or ultrasonic systems can be added to improve screening efficiency.

-

Liquid solid filters can effectively filter aqueous applications as well as high viscosity materials.

-

Vibrating sieve for liquid solid separation

In production processes,Vibrating sieve for liquid solid separation are used to recover valuable materials, purify liquids, or treat waste...

-

Tumbler Screen Solid-Liquid

A sewage treatment customer needs to perform preliminary solid-liquid separation on aquaculture wastewater...

-

Liquid vibrating screen

Liquid vibrating screen is a mechanical device specially used to separate solid particles or impurities in liquids...

-

Chemical liquid vibrating screen

Chemical liquid vibrating screen is a device used for solid-liquid separation or liquid filtration, usually used in the chemical industry to screen...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.