Swing Vibrating Screen Screening Petroleum Coke Powder

The Swing Vibrating Screen Screening Petroleum Coke Powder is designed to process fine, dusty, and potentially statically and sticky materials like petroleum coke powder. The screening particle size range for petroleum coke powder screening typically ranges from 150μm to 4.75mm. This allows for both fine classification of fine powders, such as micronized petroleum coke used in anode materials, and separation of medium and coarse particles.

Screening capacity varies significantly depending on factors such as equipment model, screen surface area, material moisture content, and particle size requirements. Small equipment can achieve an hourly output of 1-5 tons, suitable for small- to medium-scale production, while large, industrial-grade equipment can achieve high-throughput screening of 10-30 tons per hour. Screening accuracy exceeds 95%, ensuring the high quality and consistency of the petroleum coke product.

What is the screening process of Swing Vibrating Screen Screening Petroleum Coke Powder?

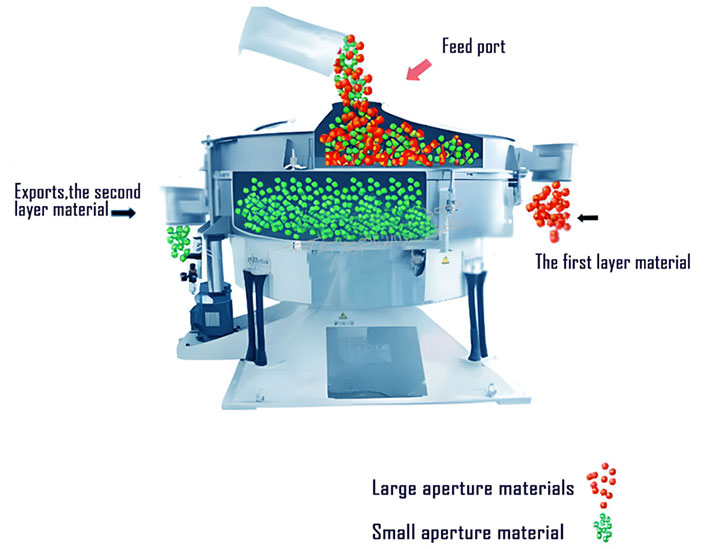

The working process of Swing Vibrating Screen Screening Petroleum Coke Powder is as follows: Petroleum coke powder is evenly fed into the inlet of the swing screen by a feeder. A motor drives the material on the screen surface, causing it to swing in a manner similar to a human hand. Fine powder quickly passes through the screen and falls into the lower hopper, becoming qualified products. Unscreened coarse powder continues to move forward along the screen surface and is discharged and collected from the discharge port. The entire process is fully enclosed, separating and preventing dust from escaping.

Swing Vibrating Screen Equipment Types for Swing Vibrating Screen Screening Petroleum Coke Powder

Swing Vibrating Screen Screening Petroleum Coke Powder Commonly used types: linear vibrating screens are suitable for screening medium- and fine-particle petroleum coke powder; circular vibrating screens are suitable for screening or impurity removal with slightly lower precision requirements; high-frequency vibrating screens are suitable for fine screening of high-moisture or ultrafine petroleum coke powder; and swing screens are suitable for medium- and fine-particle petroleum coke powder that is fragile, has high added value, or requires efficient classification. The following are screen options for swing vibrating screens for petroleum coke powder screening.

There is also a square swing vibrating screen. The structural design of this equipment makes the screen surface utilization rate more than 30% higher than that of a circular screen. A single device has a larger processing capacity and can match the production capacity requirements of large-scale production of petroleum coke powder. The gentle movement can effectively break up slight clumps and significantly reduce the impact and wear of the material on the screen. It is particularly suitable for processing fine powder materials such as petroleum coke powder that are both abrasive and easy to generate dust.

Select the number of screen layers and mesh size based on the coke fines particle size:

Coarse fines (>1mm): Choose a single-layer screen with a mesh size of 1.2-2mm to efficiently separate coarse particles from impurities;

Medium fines (0.15-1mm): Choose a 1-2-layer screen, with an upper mesh size of 1.2mm to remove coarse impurities and a lower mesh size of 0.15mm to retain medium fines;

Fine fines (<0.15mm): Choose a 2-3-layer screen, with an upper mesh size of 0.2mm to remove impurities, a middle mesh size of 0.15mm to remove fines, and a lower mesh size of 0.075mm to finely refine. The mesh size accuracy must match the target particle size.

Select Swing Vibrating Screen Screening Petroleum Coke Powder based on coke fines moisture content:

Low moisture content (<3%): Basic oscillating screen for general screening;

Medium moisture content (3%-5%): Sealed dustproof screen with bouncing ball screen cleaning to prevent clogging and control dust;

High moisture content (>5%): Ultrasonic oscillating screen, with high-frequency vibration to disperse lumps and prevent clogging.

Screen Material Selection:

Low-sulfur coke fines: Choose carbon steel woven mesh for low cost;

High-sulfur coke fines/fines: Choose 304 stainless steel mesh for corrosion resistance and anti-adhesion;

High-moisture coke fines: Choose polyurethane mesh for wear resistance and anti-adhesion, extending service life.

Swing Vibrating Screen Screening Petroleum Coke Powder Equipment Display

What are the advantages of the Swing Vibrating Screen Screening Petroleum Coke Powder?

The Swing Vibrating Screen Screening Petroleum Coke Powder can separate coke fines of varying particle sizes with stable operation and minimal material damage, making it ideal for petroleum coke fines processing.

High Screening Efficiency: Using a combined swing and vibration motion, the petroleum coke fines are evenly dispersed and quickly separated on the screen surface, reducing the problem of powder accumulation and screen clogging. The screening efficiency for fine powders in the 200-800 mesh range can reach over 95%.

Precise Grading: It can be equipped with multiple layers of screens of varying mesh sizes, separating 2-5 particle size grades simultaneously. Stable screen tension controls the particle size deviation of the finished petroleum coke powder, ensuring it meets the particle size requirements of subsequent processing (such as graphite electrode production).

Stable Operation and Low Loss: The Swing Vibrating Screen Screening Petroleum Coke Powder utilizes a sealed design to prevent dust pollution from petroleum coke powder and reduce wear on internal components. The vibrating motor power is optimally matched, resulting in an operating noise level below 85 decibels and a low failure rate.

Adaptable: The vibration frequency and swing angle can be adjusted based on the humidity and viscosity of the petroleum coke powder. Even slightly agglomerated powder can be dispersed and efficiently screened through vibration, adapting to diverse operating conditions.

Quick Facts About Petroleum Coke Powder

Petroleum coke powder is a finely powdered fuel produced by coking and grinding heavy petroleum oil. It is primarily composed of carbon, with small amounts of sulfur and ash. It features high carbon and low hydrogen content, good fluidity (particle size 200-325 mesh), easy combustion, and controlled impurities. It is used as an industrial fuel, a raw material for graphite electrodes, a reducing agent in metal smelting, and as a raw material for the production of silicon carbide and activated carbon.

The Swing Vibrating Screen Screening Petroleum Coke Powder, with its unique swing screening principle, successfully addresses numerous challenges in screening fine powders, including efficiency, accuracy, and screen clogging. From its flexible and adjustable motion parameters, diverse equipment types, to its superior anti-clogging and sealing performance, every design feature is tailored to the material properties of petroleum coke powder. It not only consistently delivers high throughput rates of several tons per hour, but also guarantees ultra-high screening accuracies exceeding 95%, directly impacting the quality and market value of the final petroleum coke product. Therefore, the Swing Vibrating Screening Petroleum Coke Powder is indispensable in petroleum coke processing, carbon manufacturing, and related industries.

-

Battery Anode Materials Vibrating Sieve

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

Remove small stones, sand or clay particles, leaves, dust and other ...

-

Standard test sieve is a screening tool used for particle size analysis of materials.

-

Standard test sieve price

Standard test sieve price usually ranges from US$20 to US$300, depending on the size, material and accuracy level...

-

Vibro Sifter Flour

The Vibro Sifter Flour uses a motor-driven eccentric weight to generate three-dimensional vibration...

-

Vibro Sifter Baking Soda

Vibro Sifter Baking Soda is a process or equipment that uses a vibrating screen to sieve, grade, or filter baking soda...

-

Linear Vibrating Screen For Plastic Particles

Linear Vibrating Screen For Plastic Particles is used for screening and grading plastic particles...

-

High -frequency vibration sieve for latex paint filter

High -frequency vibration sieve for latex paint filter is a filtration device designed for high-viscosity liquid systems such as water-based paints ...

-

Vibro Sifter Magnesium Oxide

Vibro Sifter Magnesium Oxide refers to the process of using a vibro sifter to grade and screen magnesium oxide powder...

-

Electric Automatic Sieve Shaker Vibrating Sieve Machine

Electric Automatic Sieve Shaker Vibrating Sieve Machine are commonly used in laboratories and industrial production...

-

Tumbler Screening Machines

Tumbler Screening Machines are available in carbon steel, stainless steel, and special steel to meet...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.