Linear Vibrating Screen For Plastic Particles

What is Linear Vibrating Screen for Plastic Particles?

Linear Vibrating Screen For Plastic Particles utilizes linear vibration to separate plastic particles of different sizes, achieving grading. The equipment can be configured with different mesh sizes to meet production needs; for example, 10–20 mesh separates larger particles or removes impurities; 20–40 mesh is suitable for coarse and fine grading of general plastic particles; 40–80 mesh is used for fine sieving of finer particles; and meshes above 80 mesh are suitable for grading micro-particles or powder-grade plastics. Through a multi-layer screen design (typically 2–4 layers), three- or four-stage grading can be achieved to obtain large, medium, small, and powder-grade products.

Plastic Particles Linear Vibrating Screen processing capacity is typically 50-2000 kg/h, with a sieving accuracy exceeding 95%. Screen materials include 304/316L stainless steel or polyurethane. The equipment is PLC-controlled and supports multi-stage sieving and backwashing. Plastic granules are typically lightweight, prone to static electricity, and easily drift. Linear Vibrating Screen can be equipped with a bouncing ball screen cleaning device or an ultrasonic screen cleaning system to prevent screen clogging. By adjusting the excitation force of the vibrating motor, it is possible to achieve adaptive screening for different particle characteristics.

Linear Vibrating Screen for Plastic Particles Parameters

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

How does a Plastic Particles Linear Vibrating Screen work?

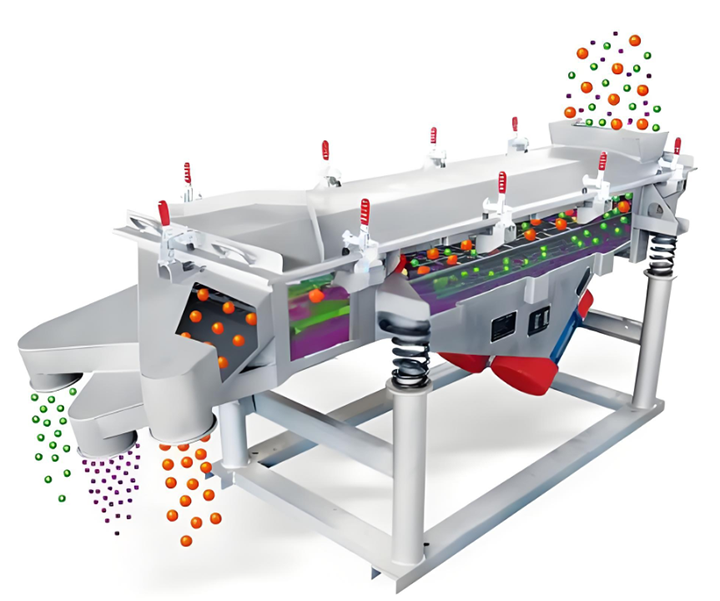

When using a Plastic Particles Linear Vibrating Screen, select the appropriate linear screen based on requirements such as screening mesh size, processing capacity, and screen material, and ensure that all components of the plastic particle linear vibrating screen are securely connected. the screen is intact and has proper tension, and the electrical wiring is not loose. Clear any debris or residual material from the surrounding area. During loading, pour the plastic particles to be screened into the feed hopper, ensuring a uniform distribution without lumps. Adjust the feed rate according to the particle size to prevent clogging of the screen. After starting the machine, connect the power cord and operate according to the instructions. Observe the stability of the vibration frequency. Control the amplitude by adjusting the angle of the eccentric block to ensure that the plastic particles are evenly dispersed and layered on the screen. Qualified particles are discharged from the lower discharge port, while impurities and substandard plastic particles are collected from the upper slag discharge port. After screening is complete, stop feeding and wait until the screen is clear of plastic particles before turning off the power cord. Clean any residual material from the screen and the interior of the machine promptly.

Linear Vibrating Screen for Plastic Particles Equipment Structure

The Plastic Particles Linear Vibrating Screen primarily consists of a screen frame, screen mesh, vibration source, and support system. Screen materials can be stainless steel, carbon steel, or polyurethane. Stainless steel or polyurethane mesh is generally recommended for plastic particles, as they are wear-resistant and non-sticky. Regarding anti-static design, plastic particles are prone to static electricity, so a grounded or anti-static vibrating screen can be used to improve safety. The vibration source can be a motor or an exciter. Choosing the right drive method can affect screening stability and energy consumption. Sealing and dust-proof design are also important. Plastic particles are light and easily dispersed, so equipment is typically equipped with a dust cover and enclosed structure to help maintain a clean workshop environment.

Application of Linear Vibrating Screen for Plastic Particles

When screening plastic particles, Plastic Particles Linear Vibrating Screen is suitable for different sizes and types of plastic particles: fine particles (0.5-2mm) such as PP, PE, and PS can be screened with stainless steel wire mesh or polyurethane mesh; medium particles (2-5mm) such as ABS, PVC, and PET are recommended to use stainless steel perforated plate or nylon mesh; hard particles (5-10mm) such as PC and PMMA can be screened with thick steel perforated plate or high-strength polyurethane mesh; large particles (over 10mm) such as engineering plastics or recycled particles should be screened with heavy-duty steel perforated mesh. Light particles should have a reduced vibration amplitude, wet or sticky particles should use anti-blocking or adjustable-angle screens, and brittle particles should be screened with flexible materials and moderate vibration to ensure product integrity.

What factors affect the processing capability of the Linear Vibrating Screen for Plastic Particles?

The capacity and efficiency of a Plastic Particles Linear Vibrating Screen in plastic particle processing depend primarily on several key parameters. First, the throughput—the number of plastic particles that can be processed daily or hourly—directly influences the screen size and number of screen layers. Generally, medium-sized plastic particles can process 2–10 tons/hour. Larger throughputs typically require wider, longer screens or multiple screen layers. Second, screening accuracy. High-precision screening is suitable for multi-layer screening to achieve particle size classification, while coarse screening can be achieved with a single or low-layer screen. Finally, the vibration frequency and amplitude are important. High-frequency, low-amplitude vibration is suitable for fine particle screening, improving separation accuracy, while low-frequency, high-amplitude vibration is suitable for coarse particles, increasing processing efficiency.

How to maintain a Plastic Particles Linear Vibrating Screen?

The following aspects should be considered when operating and maintaining a Linear Vibrating Screen for Plastic Particles: For ease of cleaning, ensure that the screen can be quickly and easily replaced to minimize production interruptions and improve efficiency. Regarding wear resistance, as long-term vibration of plastic particles can cause wear on the screen and the machine body, wear-resistant materials should be used or liners should be installed in vulnerable areas to extend service life. Regarding noise control, high-frequency vibration generates a certain amount of noise. Appropriate vibration damping devices and sound insulation measures should be designed to ensure a comfortable factory environment and compliance with safety regulations. Furthermore, routine maintenance should include regular inspections of vibration sources, fasteners, and lubrication systems to ensure stable equipment operation.

Solutions for Plastic Particles Linear Vibrating Screens

The Linear Vibrating Screen for Plastic Particles utilizes multi-layer grading and screening processes, vibration separation, uniform material distribution, dustproof sealing, anti-sticking optimization, and automatic screen cleaning to provide a solution for grading plastic granules.

The screen can employ double or triple layers of stainless steel screens. The upper screen filters large impurities and agglomerated particles, the middle screen, with a mesh size adjusted according to requirements, separates qualified particles, and the lower layer collects fine powder and debris. It is equipped with an adjustable-speed vibrating motor that adjusts the amplitude and frequency according to particle density to prevent particle accumulation. A sealed dust cover is also added to prevent dust from escaping during the screening process.

A buffer hopper and disperser are added to the feed end of the screen to ensure uniform distribution of plastic granules and improve screening efficiency. A grading collection bin is installed at the discharge port to achieve simultaneous separation and collection of qualified particles, large impurities, and fine powder. For soft plastic particles that easily stick to the screen, a Teflon coating can be sprayed onto the screen surface to reduce particle adhesion. At the same time, the screen can be cleaned regularly by an automatic screen cleaning device (such as a ball-type screen cleaner) to meet the grading and impurity removal needs in production.

As a key piece of equipment for plastic pellet processing, the Plastic Particles Linear Vibrating Screen can process lightweight, brittle, and high-moisture plastic pellets. The screen size, vibration frequency, and number of layers can be flexibly adjusted to meet diverse needs, achieving precise grading and high production output. The equipment's materials and structural design prioritize wear resistance, anti-static properties, dust resistance, and ease of operation, ensuring safe, efficient, and low-maintenance production. Through scientific configuration and optimized operation, it improves the quality of plastic pellet screening and optimizes the production environment. It is a core piece of equipment for plastic recycling and granulation, applicable throughout the entire supply chain from raw material pretreatment to finished product grading, encompassing granulation, injection molding, and modification.

-

Battery Anode Materials Vibrating Sieve

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

Vibratory Sifter Medicine Powder Sieving

Vibratory Sifter Medicine Powder Sieving is a device used in the pharmaceutical industry for fine sieving of pharmaceutical powders...

-

Standard test sieve price

Standard test sieve price usually ranges from US$20 to US$300, depending on the size, material and accuracy level...

-

Large vibrating screen equipment manufacturers

Xinxiang Dahan Machinery is a large-scale manufacturer specializing in the manufacture of vibrating screen equipment...

-

Powder Sieve Machine Price

Powder Sieve Machine Price varies depending on the specifications, and the market quotation is usually between US$500 and US$8000...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.