Vibro Sifter Flour

Vibro Sifter Flour not only precisely separates flour and bran by particle size, but also safely removes contaminants and lumps, effectively breaking up clumps and ensuring a more uniform and fluffy product. Constructed of stainless steel, this machine offers exceptional performance, with an hourly throughput of 50-1000 kg. It is also suitable for separating a variety of powders, granules, and liquid slurries, making it a versatile screening solution.

The Vibro Sifter Flour uses a motor-driven eccentric weight to generate three-dimensional vibrations to grade flour and remove impurities. It is typically used to sieve dry, free-flowing powders such as wheat flour, corn flour, and starch, typically with a moisture content of 14% or less. The mesh size typically ranges from 20 to 200, and the mesh can be changed to produce different particle sizes. Commonly used vibrating flour sifters include ultrasonic vibrating screens, inline screens, and silo vibrating screens.

How Vibro Sifter Flour Works

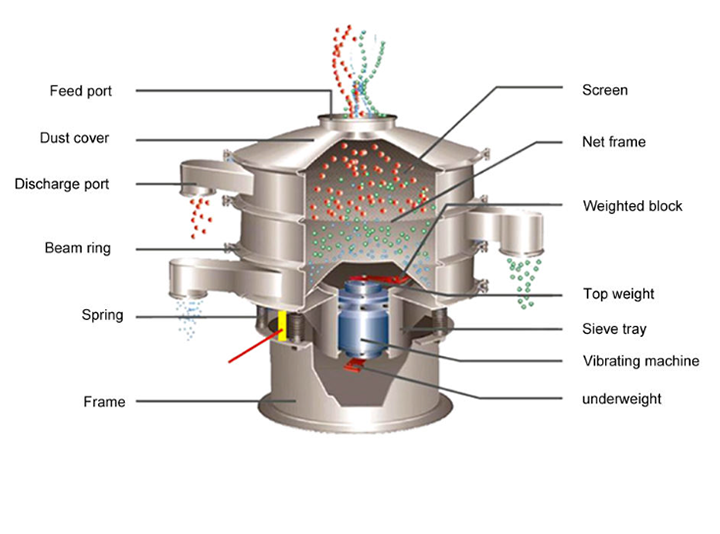

The Vibro Sifter Flour uses a vibrating motor mounted on its base or top to generate multi-dimensional vibrations, driving the flour through a unique spiral motion on the sieve. This motion not only effectively breaks up flour clumps and separates them into layers (fine particles sink to the sieve, while coarse particles float to the surface), but also continuously propels the material from the central inlet to the surrounding outlets. During this process, one or more built-in sieves of varying apertures precisely separate the flour, achieving separation of different particle sizes.

What are the benefits of the Vibro Sifter Flour?

Vibro Sifter Flour can achieve the goal of sieving coarse or fine flour by replacing 1-5 layers of screen mesh, and the vibration frequency can be changed to improve the quality of flour. The specific advantages are as follows:

High sieving efficiency: The Vibro Sifter Flour uses a vibrating motor to generate high-frequency vibrations, allowing flour to pass through the sieve quickly. Its sieving efficiency is 5–10 times higher than that of traditional manual sifters, making it ideal for large-scale processing. For example, a medium-sized vibrating screen can process 500-1000 kg of flour per hour, while manual sifting can only process a few dozen kg.

Multi-stage screening capability: The Vibro Sifter Flour can be configured with two to five layers of screens with varying mesh sizes, enabling multi-stage screening, such as separating coarse, fine, and ultrafine flours. This design improves screening accuracy and meets diverse particle size and fineness requirements.

High flour purity: The Vibro Sifter Flour's powerful vibrations break up lumps in the flour, while the screen effectively traps impurities such as bran, insect eggs, and foreign matter, ensuring a purer flour. Furthermore, by adjusting the screen mesh size (typically 80-200 mesh), the system can meet the fineness requirements of different flour types (low-gluten, medium-gluten, and high-gluten).

Versatile: The Vibro Sifter Flour can adjust its vibration frequency and amplitude based on the moisture content and viscosity of the flour, making it suitable for difficult-to-sift materials such as whole wheat flour. The screen is easily replaceable, adapting to the needs of flour sieving of varying particle sizes.

Improving Flour Quality: The Vibro Sifter Flour produces flour with a uniform and fine particle size, improving flour processing performance and the final product's taste. It also enhances flour fluidity and reduces clumping, facilitating subsequent packaging and transport.

Vibro Sifter Flour Technical Parameters

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Vibro Sifter Flour Types

Common types of Vibro Sifter Flour include ultrasonic vibrating screens, linear screens, and silo vibrating screens. Ultrasonic vibrating screens have high flour screening accuracy, linear screens have high output, and silo vibrating screens can fix the equipment, making the equipment more efficient in flour screening. The functions of these three devices in the flour screening process are as follows:

Ultrasonic vibrating screens: Utilize ultrasonic vibration technology to increase the screen's vibration frequency and screening efficiency. They effectively prevent flour particles from clogging the screen, ensuring continuous and efficient screening. They are suitable for fine-grained screening of fine powders, improving flour purity and uniformity.

Inline screens: Utilize linear vibration to evenly distribute flour across the screen, quickly separating particles. They are suitable for sieving flours of varying coarse and fine grains. They offer fast screening speeds and high throughput, making them ideal for primary screening of large batches of flour. They help remove larger impurities and lumps, ensuring flour quality.

Silo-type vibrating screen: Equipped with a silo design, it enables continuous, automatic feeding and screening of flour. The vibrating screen mesh works in conjunction with the silo to reduce flour dust and improve material flowability. It is suitable for multi-stage screening processes, capable of grading flours of varying particle sizes. It improves screening stability and automation, reducing manual intervention.

What equipment can I use with the Vibro Sifter Flour?

The Vibro Sifter combined with an airflow screen effectively improves flour screening efficiency and accuracy. The vibrating screen quickly separates large impurities, while the airflow screen is used to finely screen ultrafine powder and light impurities after the Vibro Sifter, reducing dust and improving the working environment. Furthermore, this combined screening process protects flour quality, minimizes mechanical damage, and adapts to various flour processing needs.

The Vibro Sifter Flour combined with a screw conveyor achieves integrated flour screening and conveying, improving production efficiency. The vibrating screen efficiently screens impurities, while the screw conveyor stably transports material, reducing dust contamination and material loss. The two work together to save labor and space, reduce energy consumption and maintenance costs, ensure flour quality, adapt to the needs of continuous automated production, and improve overall processing efficiency and production safety.

Vibro Sifter Flour and bucket elevators are commonly used in flour production lines. Bucket elevators lift flour or raw materials vertically to a certain height and convey them to the inlet of a vibrating screen. The vibrating screen removes impurities and particles from the flour through vibration, achieving screening and purification. The combination of the two improves production efficiency and product quality, ensuring pure and fine flour suitable for subsequent processing.

Vibro Sifter Flour Common Applications

The Ultimate Purification of Flour Production

After flour is ground by the mill, the Vibro Sifter Flour is responsible for purification and fine screening. It effectively separates trace bran fibers that may remain after grinding, flour clumps caused by moisture or static electricity, and extremely fine process impurities. Equipped with fine 80- to 120-mesh screens, this equipment ensures the fineness and purity of flour before it leaves the factory, producing a uniform, fine-grained, and ready-to-package finished flour.

Pretreatment of Flour Before the Production Line

In factories manufacturing foods like bread, biscuits, and noodles, vibrating screens are critical pretreatment equipment for flour before it enters the production line. They break up clumps formed during storage and transportation, remove fine foreign matter such as paper scraps and plastic shreds, and, through vibration, thoroughly mix the flour with air, achieving a "aeration and oxygenation" effect. This process provides standardized, stable, and impurity-free raw materials for subsequent production.

Sieving and Homogenizing Additives

When adding trace additives such as vitamins, improvers, or enzymes to flour, a vibrating screen performs both sieving and mixing. It first finely sieves these easily agglomerated additives to ensure their dispersion, then evenly distributes them into the flowing flour during the sieving process. This process ensures efficient pre-mixing, fundamentally avoiding the problem of uneven distribution of additives leading to excessive or ineffective local ingredients in food.

Precise Grading and Compounding of Specialty Flours

To meet specific food requirements, the Vibro Sifter Flour can precisely grade flour using sieves of varying mesh sizes. For example, flour for soft and fluffy cakes requires a high-mesh sieve of 140 or higher to remove coarse particles; while dumpling flour requires grading to balance gluten content and texture. When producing mixed grain flours, it also ensures a more even and fluffy blend of various powders while simultaneously removing common impurities, resulting in a specialized product with defined particle size and texture.

Universal Processing of Starch and Various Grain Flours

Vibrating screens also extend to the processing of starches (such as corn and tapioca starch) and other grain flours (such as rice flour and glutinous rice flour). These materials are highly susceptible to moisture absorption and agglomeration, making vibrating screens essential for processing before packaging or use. They effectively break up lumps, remove impurities, and restore the powder's fluidity and fineness, which are crucial for the starch's effectiveness in functional applications such as thickening.

The Vibro Sifter Flour plays an irreplaceable and important role in the flour processing process. It not only removes impurities from flour, ensuring its purity and quality, but also improves its fineness and uniformity through scientific screening and grading, thereby meeting the diverse needs of different customers and markets. Furthermore, the vibrating screen is easy to operate and maintain, energy-saving and environmentally friendly, and significantly improves production efficiency and product stability. When choosing a Vibro Sifter Flour machine, you can select it based on the mesh size requirements, output and equipment functions. At the same time, choosing equipment that can be used in combination can further improve efficiency.

-

Standard test sieve is a screening tool used for particle size analysis of materials.

-

Graphite Powder Sieving Machine

Graphite powder sieving machine is specially developed to solve the problem of graphite powder sieving...

-

Powder sieving machine is designed for high volume sieving of powders to remove oversized contaminants ...

-

metal powder sieving machine sends ultrasonic waves to the surface of the sieve to prevent clogging or damage of the sieve...

-

Vibro Sifter Baking Soda

Vibro Sifter Baking Soda is a process or equipment that uses a vibrating screen to sieve, grade, or filter baking soda...

-

Vibro Sifter Magnesium Oxide

Vibro Sifter Magnesium Oxide refers to the process of using a vibro sifter to grade and screen magnesium oxide powder...

-

Standard test sieve price

Standard test sieve price usually ranges from US$20 to US$300, depending on the size, material and accuracy level...

-

How much is an abrasive automatic sieving machine?

Abrasive automatic sieving machine is a commonly used industrial powder sieving equipment, widely used in metallurgy...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.