Vibro Sifter Baking Soda

What is Vibro Sifter Baking Soda?

Vibro Sifter Baking Soda uses efficient vibration to separate fine particles from coarse ones and break up clumps, thereby improving the quality of baking soda in baking, food processing, and industrial applications. This equipment accurately separates wet and dry materials, offering low noise and high efficiency. Available in a variety of models, from industrial-grade powder sifters with a throughput of up to 50 kg/h to compact household models, it meets the needs of diverse applications.

Vibro Sifter Baking Soda uses a vibrating motor to drive a screen to screen, grade, and remove impurities from baking soda. The commonly used mesh size range is 20 to 200 mesh, with an hourly output of 500-5,000 kg. The raw materials are dried, crushed, and evenly fed into the screen. Linear, rotary, or ultrasonic vibrations are used to effectively remove lumps and impurities, control particle distribution, and ensure product uniformity for baking and chemical applications. Common baking soda screening equipment includes linear vibrating screens, circular vibrating screens, and ultrasonic vibrating screens.

How a vibro sifter works with baking soda

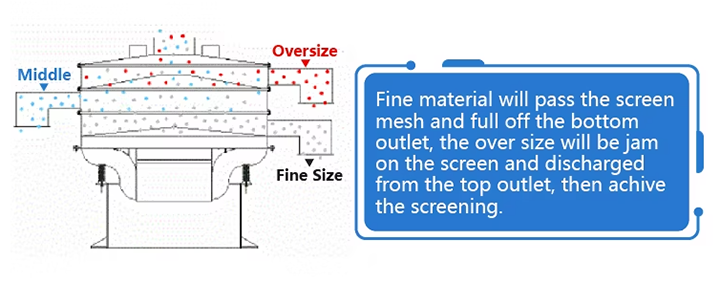

Vibrating screens are used in baking soda processing to screen, remove impurities, and grade the baking soda material through the high-frequency vibrations generated by a vibrating motor, combined with the grading function of the screen mesh.

Material Feed: Baking soda containing lumps or impurities enters the vibrating screen frame through the feed inlet and is initially distributed on the top screen surface.

Vibratory Screening: The vibrating motor drives the screen frame to vibrate at high frequencies in a specific pattern, causing the baking soda particles to bounce and disperse on the screen mesh. Fine baking soda particles that fit within the mesh apertures pass through the mesh and enter the collection area below. Agglomerated, large impurities, or undispersed material remain on the mesh surface and are ultimately discharged through the slag outlet at the end of the mesh.

Grading and Collection: To grade baking soda into different particle sizes, a multi-layered screen structure can be used. Screens of varying apertures separate the baking soda into multiple particle size grades. The material from each layer enters its corresponding collection hopper, resulting in a high-purity, uniformly sized finished baking soda product.

What are the common types of equipment used for Vibro Sifter Baking Soda?

Common equipment Vibro Sifter Baking Soda includes linear vibrating screens for primary screening; circular vibrating screens for fine grading; and ultrasonic vibrating screens designed for ultrafine screening.

Linear vibrating screens are commonly used for baking soda screening. They consist primarily of a screen box, dual vibrating motors, shock-absorbing springs, and 304/316 stainless steel screens. They utilize linear reciprocating motion for screening. This equipment is suitable for primary screening and impurity removal of baking soda with mesh sizes of 20-200, with a throughput of 0.5-5 tons/hour. It offers stable operation and high throughput, but is prone to screen clogging when screening fine powders above 300 mesh, requiring an anti-clogging device. The screens are available in single or multi-layer designs, allowing for flexible adjustment of mesh size according to baking soda particle size.

Vibro Sifter Baking Soda Another commonly used equipment is a circular vibrating screen, which is used for screening fine baking soda.. Driven by a vertical vibrating motor, they feature multi-layer nylon or stainless steel screens, a sealing cover, and a bouncing ball screen cleaning device. This equipment can process baking soda with mesh sizes of 30-400, with a capacity of 0.1-3 tons/hour. It is particularly suitable for the fine grading of food-grade baking soda, featuring high screening accuracy and excellent dust resistance. It utilizes a 2-5-layer screen design, with the upper layer removing impurities and the lower layer performing fine screening. An ultrasonic screen cleaning system can be added to prevent clogging, but auxiliary cleaning is still required when processing ultrafine powders above 400 mesh.

The ultrasonic vibrating screen is specifically designed for ultrafine screening of baking soda. It incorporates an ultrasonic generator and transducer in addition to the rotary vibrating screen. It can efficiently process pharmaceutical-grade and nano-grade baking soda with mesh sizes of 100-600, with a capacity of 0.05-1 ton/hour. Its high-frequency ultrasonic vibration effectively prevents agglomeration and screen clogging of ultrafine powders. The equipment utilizes a specially designed high-mesh stainless steel dense mesh or microporous screen plate, and the continuous ultrasonic vibration significantly reduces manual cleaning.

Vibro Sifter Baking Soda Technical Specifications

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Mesh Size Range for Mesh Size Range for Vibro Sifter Baking Soda

Baking soda can be sieved with the Vibro Sifter Baking Soda to obtain a variety of sizes ranging from 10 to 500 mesh. Each mesh size range corresponds to a different particle size and application, and is widely used in the livestock, food, pharmaceutical, cosmetic, and chemical industries.

Coarse baking soda (10-40 mesh) is commonly used as a livestock feed additive, chemical raw material, and swimming pool conditioner. Medium baking soda (40-100 mesh) is suitable for use in leavening agents, laundry detergents, and detergents. Fine baking soda (100-200 mesh) is primarily used in pharmaceutical formulations, fine chemicals, and as a foaming agent in certain foods and beverages. Ultrafine baking soda (200-300 mesh) can be used as a tobacco additive, laboratory reagent, and toothpaste abrasive. Micronized baking soda (300-500 mesh) is suitable for use in high-end food seasonings and cosmetics, such as facial masks and scrubs. Ultrafine baking soda (500 mesh and above) is a micronized product used in pharmaceutical coatings, ultrafine polishing, and as a catalyst carrier for specialty chemicals.

The main properties of baking soda

Given baking soda's hygroscopic, slightly abrasive, and weakly alkaline properties, the equipment utilizes 304/316 stainless steel screens. These screens are resistant to mild alkaline corrosion from baking soda and offer a smooth surface, reducing powder adsorption and clumping. Plain-weave square-hole screens are also suitable for use, as they offer a sturdy structure and high screening accuracy, making them the preferred choice for handling baking soda powder. Food-grade silicone bouncing balls or ultrasonic screen cleaning systems installed beneath the screens can address the possibility of clogging caused by even mild moisture. The feed and discharge ports should be designed with flanges or quick-release clamps for easy connection to pipes and hoses, ensuring sealed conveying throughout the entire production line.

Vibro Sifter Baking Soda Applications

The Vibro Sifter Baking Soda's primary functions in baking soda processing are to remove impurities, control particle size, improve mixing uniformity, and ensure consistent product quality.

Food Industry: Baking soda is widely used in baking, seasoning, and confectionery production. The Vibro Sifter Baking Soda can be used to grade and sieve the powder, effectively removing lumps and impurities and ensuring a uniform and consistent powder.

Pharmaceutical and Healthcare Products Industry: In pharmaceutical production, baking soda is often used as a neutralizing agent or buffer in tablets and effervescent tablets. Sieving with a Vibro Sifter Baking Soda ensures uniform particle size and prevents formulation instability.

Chemical Industry: In the fine chemical industry, baking soda is used in chemical reactions, cleaning agents, and desiccants. The Vibro Sifter Baking Soda is used to process baking soda powder, remove impurities, and precisely control particle size.

Environmental Protection and Other Industries: Baking soda is used in air purification and water treatment to neutralize acidic pollutants. The Vibro Sifter Baking Soda helps prepare adsorbents with uniform particle size, improving treatment efficiency.

Vibro Sifter Baking Soda Supplier

Our factory has over 15 years of manufacturing experience. Our Vibro Sifter Baking Soda is made of high-quality stainless steel. It can sieve fine powders up to 0.028mm and accurately separate impurities from baking soda. Models range from 400mm to 2000mm. Support trial runs with raw materials and provide comprehensive after-sales service. We are a trustworthy manufacturer.

The Vibro Sifter Baking Soda plays a critical role in the baking soda production process. After production, baking soda requires fine sieving through various equipment to obtain products that meet specific application and particle size requirements. The Vibro Sifter Baking Soda utilizes high-frequency vibration and a multi-layered screen design to efficiently separate baking soda particles of varying sizes, ensuring uniformity and consistent quality across each batch. This equipment can accurately screen both coarse baking soda for industrial applications and fine powder for food, medicine, and other fields. Furthermore, the screening equipment boasts a rational structure, simple operation, and easy maintenance. This not only improves production efficiency but also effectively reduces material waste, ensuring the continuity and reliability of the production process.

-

Battery Anode Materials Vibrating Sieve

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

metal powder sieving machine sends ultrasonic waves to the surface of the sieve to prevent clogging or damage of the sieve...

-

Vibratory Sifter Medicine Powder Sieving

Vibratory Sifter Medicine Powder Sieving is a device used in the pharmaceutical industry for fine sieving of pharmaceutical powders...

-

Vibro Sifter Flour

The Vibro Sifter Flour uses a motor-driven eccentric weight to generate three-dimensional vibration...

-

Silicon powder for test sieve

Silicon powder for test sieve commonly used in various industrial applications, including electronics, metallurgy....

-

Vibrating Sieve Rapeseed

Vibrating Sieve Rapeseed uses the excitation force generated by a vibrating motor to create three-dimensional vibrations on the screen...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.