Tumbler Screening Machines

What are Tumbler Screening Machines?

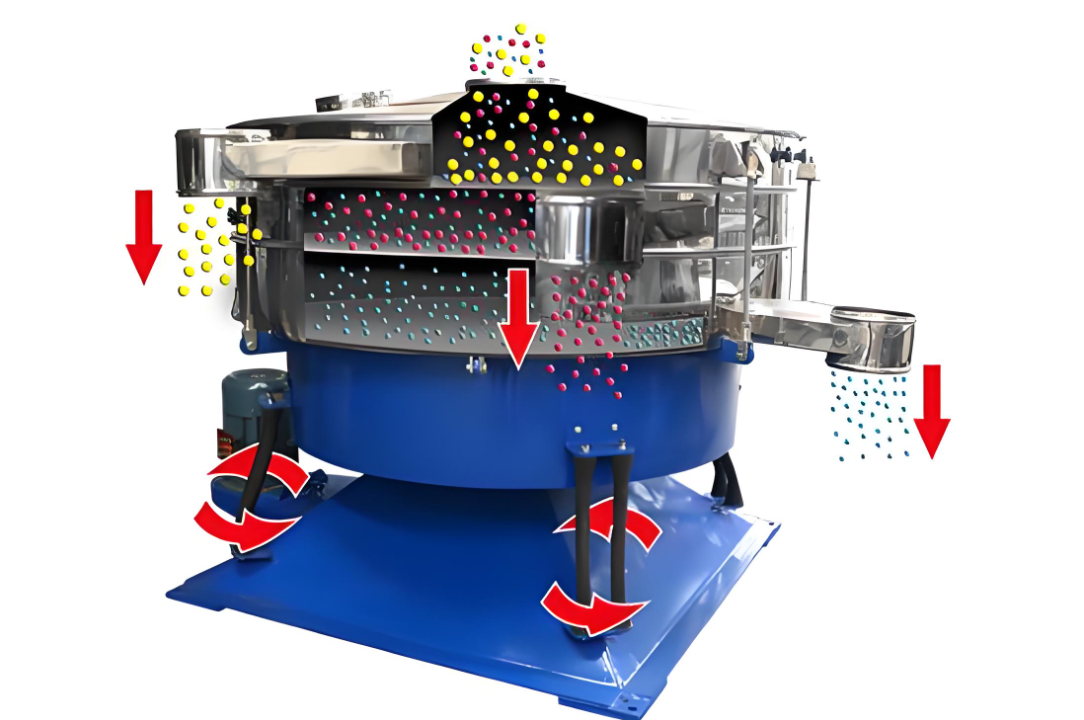

Tumbler Screening Machines are available in carbon steel, stainless steel, and special steel to meet diverse operating requirements, such as corrosion resistance, wear resistance, and anti-static properties. Using a rocking motion, these machines classify, remove impurities, separate solids and liquids, and perform particle size analysis on powders and granular materials.

Tumbler Screening Machines excel at handling fine powders and irregular particles that are prone to dusting, require high precision, high density, are prone to adhesion, and carry static electricity, without disrupting the material's shape. With a single machine throughput of 1 kg/h to 50 t/h, they can screen particle sizes ranging from 25 mm to 37 microns (400 mesh) and even finer. These machines are typically configured with one to five screen layers, allowing for simultaneous separation of two to six different product sizes.

Tumbler Screening Machines Video Showcase

Advantages of Using Tumbler Screening Machines

Tumbler Screening Machines have advantages like high screening efficiency, good separation effect for fine materials, low noise, stable operation, and adaptability to various granular, powdery or pasty materials.

High Adaptability: Suitable for screening chemicals, metal powders, food ingredients, plastic granules, and other materials, whether dry, wet, or containing oil.

Wide Particle Size Range: Capable of processing ultrafine powders (20–200 μm) to coarse particles (10–50 mm), it achieves precise grading from 2 to 6 grades using multiple screens.

High Screening Accuracy: Unique three-dimensional elliptical motion simulates manual screening, extending material residence time on the screen surface, enabling grading, impurity removal, and solid-liquid separation, achieving purities exceeding 95%.

Anti-Clog Design: Tumbler Screening Machines gentle motion reduces screen clogging for materials prone to agglomeration, static electricity, or moisture, making cleaning and maintenance easier.

Durable Material: Available in corrosion-resistant 304 or 316 stainless steel, suitable for acidic, alkaline, or special chemical environments, while also meeting food-grade, pharmaceutical-grade, and explosion-proof requirements.

High Capacity, Low Energy Consumption: High throughput, stable operation, low noise, and low energy consumption make it suitable for continuous production.

Safe and Reliable: Suitable for flammable, explosive, or volatile materials, the design complies with explosion-proof and safety regulations to ensure safe production.

Parameters of Common Tumbler Screening Machines

Tumbler Screening Machines are available in a variety of materials, including stainless steel wire mesh, mild steel wire mesh, polyester mesh, nylon mesh, and specially coated mesh. Screen diameters range widely, from 400mm to over 2000mm, and are customizable. The figure below shows the parameters of common Tumbler Screening Machine models:

| Particle feed size: | 1 micron up to 20 mm | ||||||

| Feed rates: | 1kg/h – 50 ton/h | ||||||

| Bulk densities: | 20 – 10000 grams/liter | ||||||

| Mesh openings: | 20 microns to 20 mm | ||||||

| Screens usable: | 304, 316L, or 430 stainless steels or plastic wire mesh fabric, perforated plates | ||||||

| No. of screen decks: | 1 – 6 per machine | ||||||

| Anti-blinding systems: | – Rubber balls | ||||||

| – Rotating roller brush arms | |||||||

| – Rotating air-jet nozzle arms | |||||||

| – Ultrasonic | |||||||

| – Combinations | |||||||

| Speed range: | 180-280 min-1 | ||||||

| Screen movement: | Three-dimensional, set to product | ||||||

| Amplitude: | 40-80 mm horizontally and 5-40 mm vertically | ||||||

| Acceleration: | 1,3-1,8 g | ||||||

| Model sizes/ca. Ø: | 600 | 1000 | 1200 | 1600 | 2000 | 2400 | 2600 |

| Screening surface (m²): | 0.292 | 0.785 | 1.13 | 1.83 | 2.63 | 4.52 | 5.31 |

| Motor power (kW): | 0.25 | 1.5 | 2.2 | 2.2 | 4 | 5.5 | 5.5/7.5 |

| Materials: | Carbon steel, Stainless and Special steels | ||||||

| Surfaces: | Painted, brushed or ground, mirror or electro polished, and ViwateQ options for Food and Pharmaceutical products with a surface roughness of < 0.4 microns (GMP, FDA compliant). | ||||||

Operating Principle of Tumbler Screening Machines

Tumbler Screening Machines during operation, a motor, through a specially designed transmission system, drives the screen in an elliptical oscillating motion, mimicking manual screening. The material on the screen first moves in a horizontal circular motion, gradually spreading outward. Then, a slight vertical tossing motion occurs, causing fine particles to pass quickly through the screen and coarse particles to move toward the discharge end. This motion not only loosens the material, preventing clumping and screen blockage, but also prolongs the material's residence time on the screen, improving screening accuracy and efficiency. Throughout this process, the screen remains tensioned, preventing localized wear and further enhancing screening consistency and stability.

Tumbler Screening Machines Applications

Tumbler Screening Machines, with their high precision, high mesh utilization, anti-clogging screens, and dust-proofing, are suitable for virtually all industrial applications requiring sizing, impurity removal, and filtering of dry powder or granular materials.

The food industry screens flour, powdered sugar, starch, yeast, salt, MSG, milk powder, soy milk powder, juice powder, seasonings (pepper, chili powder), tea, dehydrated vegetables, and food additives.

The pharmaceutical and cosmetics industries screen traditional Chinese medicine powders, Western medicine raw material powders, pill granules, health supplement powders, creams, facial mask powders, talc, pearl powder, rouge, eye shadow, and other cosmetic ingredients.

The chemical and plastics industries tumbler screening machines screen resins, pigments, dyes, coatings, powder coatings, PVC powder, additives, fillers, laundry detergents, pesticides, rubber granules, and plastic masterbatches.

The metallurgy and mining industries screen metal powders (iron, aluminum, copper), alloy powders, abrasives (corundum, silicon carbide), quartz sand, kaolin, mica powder, and ore particles.

The ceramics and building materials industries tumbler screening machines screen glazes, ceramic powders, glass powder, graphite powder, cement additives, refractory materials, gypsum powder, and more.

Tumbler screening machines address the pain points of traditional vibrating screens when processing specialized materials, including low efficiency, clogging, high dust generation, and substandard accuracy. Whether you're looking to improve product quality, optimize production processes, or create a cleaner and safer working environment, choosing the right vibrating screen is a worthwhile investment.

-

Battery Anode Materials Vibrating Sieve

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

Remove small stones, sand or clay particles, leaves, dust and other ...

-

Standard test sieve is a screening tool used for particle size analysis of materials.

-

Pharmaceutical powder vibrating screen

Pharmaceutical powder vibrating screen is a specialized device used for screening pharmaceutical powders...

-

Vibratory Sifter Medicine Powder Sieving

Vibratory Sifter Medicine Powder Sieving is a device used in the pharmaceutical industry for fine sieving of pharmaceutical powders...

-

Standard test sieve price

Standard test sieve price usually ranges from US$20 to US$300, depending on the size, material and accuracy level...

-

Vibro Sifter Flour

The Vibro Sifter Flour uses a motor-driven eccentric weight to generate three-dimensional vibration...

-

Vibro Sifter Baking Soda

Vibro Sifter Baking Soda is a process or equipment that uses a vibrating screen to sieve, grade, or filter baking soda...

-

Linear Vibrating Screen For Plastic Particles

Linear Vibrating Screen For Plastic Particles is used for screening and grading plastic particles...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.