Standard test sieve

![[field:title/]](/uploads/241028/1-24102Q000541M.jpg)

Callback

| Aperture size: 0.02-2.36 mm | Material: 304 stainless steel / brass / chrome-plated |

Frame diameter: 500/400/300/200/120/80/75mm, or other sizes provided according to your requirements.

Surface type: Woven wire mesh / perforated plate / electroformed mesh

What is Standard test sieve?

Standard test sieve is a precision tool for particle size analysis and classification of granular materials, used to screen and separate materials of different particle sizes. It is mainly used in laboratories to perform standard inspections, screening, filtering, and testing on the particle size structure, liquid solid content, and impurity content of granular and powdery materials. It can automatically stop and can accurately separate 2 to 7 particle segments of granular materials at the same time.

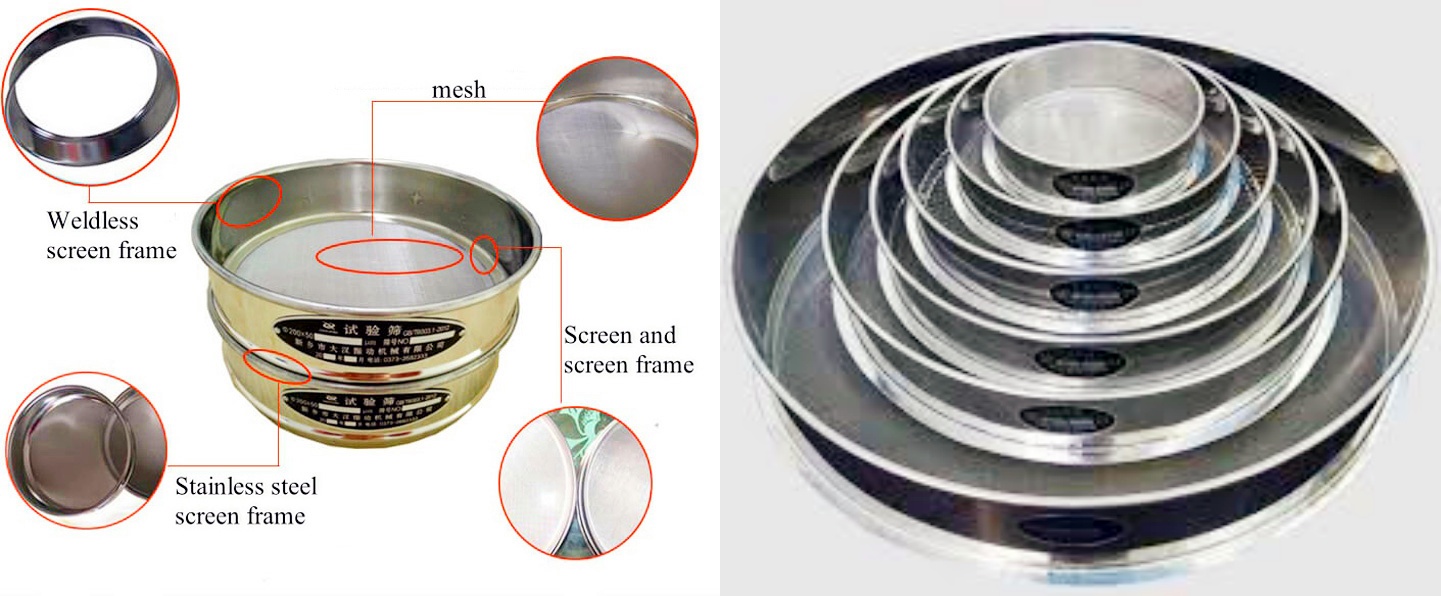

Standard test sieve frames commonly come in diameters of Φ200mm and Φ300mm, but Φ75mm and Φ450mm are also available. The height is typically 50mm or 25mm. The frames are primarily made of 304 or 316 stainless steel for corrosion resistance, though some are made of chrome-plated copper alloy for enhanced wear resistance. The mesh is mostly woven from 304 stainless steel, with brass mesh used in specific applications. High-precision screening utilizes nickel-plated sieves, while perforated metal sieves are used for coarse-grained materials.

What are the characteristics of Standard test sieve?

The Standard Test Sieve utilizes a high-precision micro-mesh sieve, capable of sieving particles from 0.025 to 3 mm with high accuracy. Lightweight and portable with a built-in handle, it's easy to move and can be quickly set up in the laboratory or on-site. Its platform design eliminates the need for fixed installation; it can be placed directly on a workbench. It also supports programmable automatic shutdown, with the timer adjustable from 1 minute to 24 hours, preventing operational errors and ensuring stable and reproducible experimental results. The entire unit is constructed of wear-resistant and high-temperature-resistant 304 stainless steel with an anti-corrosion treatment, ensuring stable operation even in humid and dusty environments.

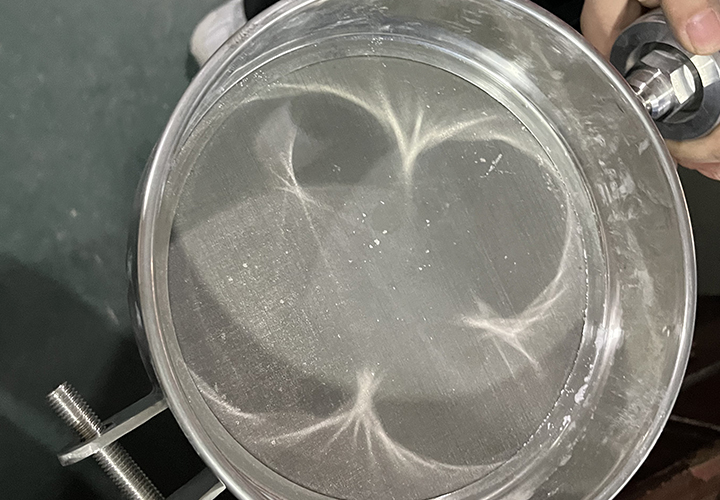

The structure of standard test sieve

Standard test sieve consists of several parts: a sieve frame, a sieve mesh, a sieve cover, a sieve bottom, and a base. The sieve frame is circular and is usually made of corrosion-resistant metals such as stainless steel or brass, making it sturdy and durable while ensuring sieving accuracy. The sieve mesh is the core component, available in two types: wire mesh and perforated plate. The aperture diameters are manufactured strictly according to standards such as ISO, GB, ASTM, and JIS, ensuring precise dimensions. The sieve cover prevents material from spilling out during sieving; the sieve bottom and base are responsible for catching the sieved material, preventing sample loss.

What types of standard test sieve are there?

Standard test sieves can be categorized by material and manufacturing process into brass sieves, nylon sieves, stainless steel sieves, perforated sieves, round-hole sieves, and woven mesh sieves. Brass sieves are inexpensive and suitable for general particle size analysis. Nylon sieves are lightweight, wear-resistant, and anti-static, and are often used for non-corrosive materials. Stainless steel sieves, mostly made of 304 or 316 stainless steel, are corrosion-resistant, high-temperature resistant, and have a long service life, making them suitable for precision grading and handling corrosive materials. Perforated sieves are made from stamped metal sheets, offering various hole shapes and high sieving accuracy, and are commonly used for sieving large particles. Round-hole sieves, mostly made of stainless steel or brass, have uniform and rounded meshes and are mainly used for particle grading and size inspection. Woven mesh sieves are made of woven metal wires, with fine mesh and good air permeability, and are commonly used for sieving powders and fine particles.

How does the standard test sieve work?

The working principle of the standard test sieve is based on the principle of vibration screening. The test sieve is usually composed of a sieve frame, a screen, a vibration mechanism and a support structure. When the test sieve is started, the vibration force generated by the vibration mechanism is transmitted to the sieve frame, causing the sieve frame and the screen to vibrate. After the particles are put into the sieve frame, they are affected by the vibration force and jump on the screen. Small particles fall into the container below through the sieve holes, while large particles remain on the surface of the screen. Through screens of different specifications, particles of different sizes can be separated and classified. Particles are separated during vibration, and the screening effect is affected by parameters such as amplitude and frequency. After screening, particle size analysis can be performed based on particle distribution to provide data support for production process optimization and product quality control.

Recommended table of standard test sieve mesh numbers

Standard test sieves allow you to select the appropriate mesh size based on the particle size of the material to be sieved. The equipment can sieve from 5 mesh to 500 mesh. A detailed mesh size table is provided below for reference.

|

Mesh number (Mesh) |

sieve hole diameter (mm) |

sieve hole diameter (μm) |

applicable fields |

|

5 |

4.000 |

4000 |

sand, ore, coarse granular materials |

|

10 |

2.000 |

2000 |

sand, chemical granules, coarse grains |

|

20 |

0.850 |

850 |

granular fertilizer, plastic granules |

|

40 |

0.425 |

425 |

cement, flour, medicinal powder coarse sieve |

|

60 |

0.250 |

250 |

fine chemical powder, Pesticide powder |

|

80 |

0.180 |

180 |

graphite powder, pigment powder |

|

100 |

0.150 |

150 |

ceramic powder, food additives |

|

120 |

0.125 |

125 |

metallurgical powder, mineral powder |

|

200 |

0.075 |

75 |

fine chemicals, pharmaceutical powder |

|

300 |

0.050 |

50 |

ultrafine powder, carbon powder |

|

400 |

0.038 |

38 |

nanomaterials, catalysts |

|

500 |

0.025 |

25 |

ultrafine chemicals, pharmaceutical powder |

Standard test sieves are manufactured to conform to ASTM E11 standards. The following details the standard particle sizes and corresponding sieve numbers.

| Standard | Altern. | Standard | Altern. | Standard | Altern. |

|---|---|---|---|---|---|

| 125.00 mm | 5.00 | 9.50 mm | 3/8 | 425 µm | No. 40 |

| 106.00 mm | 4.24 | 8.00 mm | 5/16 | 355 µm | No. 45 |

| 100.00 mm | 4 | 6.70 mm | 0.265 | 300 µm | No. 50 |

| 90.00 mm | 3 ½ | 6.30 mm | ¼ | 250 µm | No. 60 |

| 75.00 mm | 3 | 5.60 mm | No. 3 ½ | 212 µm | No. 70 |

| 63.00 mm | 2 ½ | 4.75 mm | No. 4 | 180 µm | No. 80 |

| 53.00 mm | 2.12 | 4.00 mm | No. 5 | 150 µm | No. 100 |

| 50.00 mm | 2 | 3.35 mm | No. 6 | 125 µm | No. 120 |

| 45.00 mm | 1 ¾ | 2.80 mm | No. 7 | 106 µm | No. 140 |

| 37.50 mm | 1 ½ | 2.36 mm | No. 8 | 90 µm | No. 170 |

| 31.50 mm | 1 ¼ | 2.00 mm | No. 10 | 75 µm | No. 200 |

| 26.50 mm | 1.06 | 1.70 mm | No. 12 | 63 µm | No. 230 |

| 25.00 mm | 1 | 1.40 mm | No. 14 | 53 µm | No. 270 |

| 22.40 mm | 7/8 | 1.18 mm | No. 16 | 45 µm | No. 325 |

| 19.00 mm | ¾ | 1.00 mm | No. 18 | 38 µm | No. 400 |

| 16.00 mm | 5/8 | 850 µm | No. 20 | 32 µm | No. 450 |

| 13.20 mm | 0.530 | 710 µm | No. 25 | 25 µm | No. 500 |

| 12.50 mm | ½ | 600 µm | No. 30 | 20 µm | No. 635 |

| 11.20 mm | 7/16 | 500 µm | No. 35 |

Different types of standard test sieves offer different options for sieve frame height and material, as well as varying woven mesh diameters and sieve heights. The appropriate combination should be selected based on the specific application of the material.

| Diameter | Full Height | Half Height | Extra depth | Frame Material |

|---|---|---|---|---|

| 8" | 2" | 1" | 4", 8" | Stainless Steel |

| 12" | 3" | 1" | 6" | Stainless Steel |

| 100 mm | 40 mm | - | Stainless Steel | |

| 200 mm | 50 mm | 25 mm | 100 mm, 200 mm | Stainless Steel |

| 300 mm | 75 mm | 40 mm | Stainless Steel | |

| 400 mm | 65 mm | - | Stainless Steel | |

| 450 mm | 100 mm | 60 mm | 300 mm | Stainless Steel |

For perforated standard test sieves, diameters range from 8 inches to 450 mm. These sieves are also available in full-height and half-height versions. The table below provides detailed parameter information.

| Diameter | Full Height | Half Height | Frame Material |

|---|---|---|---|

| 8" | 2" | 1" | Stainless Steel |

| 12" | 3" | 1" | Stainless Steel |

| 200 mm | 50 mm | 25 mm | Stainless Steel |

| 300 mm | 75 mm | 40 mm | Stainless Steel |

| 400 mm | 65 mm | - | Stainless Steel |

| 450 mm | 100 mm | - | Stainless Steel |

Standard test sieves typically use stainless steel for the frame material, and sieve diameters are available in 8-inch, 12-inch, 200 mm, and 450 mm sizes.

| Diameter | Frame Material |

|---|---|

| 8" | Stainless Steel |

| 12" | Stainless Steel |

| 100 mm | Stainless Steel |

| 200 mm | Stainless Steel |

| 300 mm | Stainless Steel |

| 400 mm | Stainless Steel |

| 450 mm | Stainless Steel |

How many types of mesh are there for standard test sieves?

Standard test sieves come in three common types: metal mesh, perforated mesh, and electroformed mesh. Perforated mesh has the largest mesh size, electroformed mesh is used for high-precision screening, and metal mesh has the most commonly used mesh size.

The first type of standard test sieve is woven wire mesh, a commonly used type with apertures ranging from 0.02 to 2.36 mm, all in square mesh. It is inexpensive, flexible, suitable for most powder sieving, and offers relatively high precision. However, there is a certain allowable deviation in mesh size, and the mesh may deform over time. Achieving precise aperture requires stabilization through aperture enlargement, aperture reduction, or electrochemical treatment, necessitating manufacturers with high-precision production capabilities to guarantee batch quality. This type of sieve has wide applications, especially in the diamond industry, where export manufacturers have strict requirements for dimensional tolerances, with a basic particle content exceeding 90%.

The second type of standard test sieve is perforated plate mesh, often used for large-sized apertures, ranging from 0.2 mm to several hundred millimeters. Hole shapes include round, square, oblong, triangular, diamond, and staggered patterns. It is manufactured by directly punching holes in sheet metal using a stamping machine, and common materials include stainless steel, aluminum, hot and cold-rolled steel, copper, and PVC film. This type of sieve is highly impact-resistant, precise, and resistant to deformation, making it suitable for screening large particles such as sand, gravel, and coal. It is commonly used for the detection and grading of large particles and is a popular choice for processing coarse materials.

The third type of standard test sieve is the electroformed sieve, a high-precision screening sieve manufactured using an electrochemical process. It achieves a precision of 1 micrometer and can be used for the accurate analysis of ultrafine powders such as nanomaterials. The error of each mesh opening is controlled within a very small range, and the mesh structure is rigid and does not deform, resulting in a more concentrated and accurate particle size distribution. Compared to woven sieves, electroformed sieves are cleaner to produce, require less daily maintenance, have a longer service life, and better filtration efficiency, improving testing efficiency. They are widely used in high-precision scenarios such as ultrafine particle size analysis in laboratories.

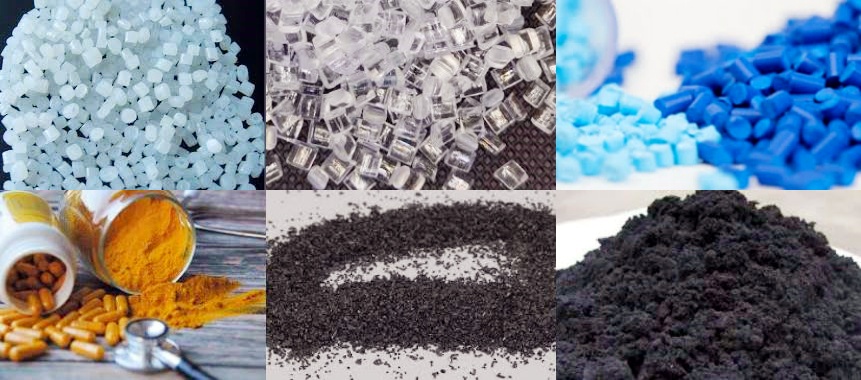

Scope of application of standard test sieves

The Standard Test Sieve can be used in research institutions and testing organizations to perform particle size distribution testing, quality inspection, and particle size classification of granular and powdered materials. It can analyze the particle size and distribution of granular materials such as sand, ore, and metal powder, and can also perform fineness testing on powdered materials such as cement, flour, and pharmaceutical powder to determine whether the product meets quality requirements. Furthermore, it can conduct screening experiments in laboratories and quality inspection settings to complete particle size classification tests for different materials.

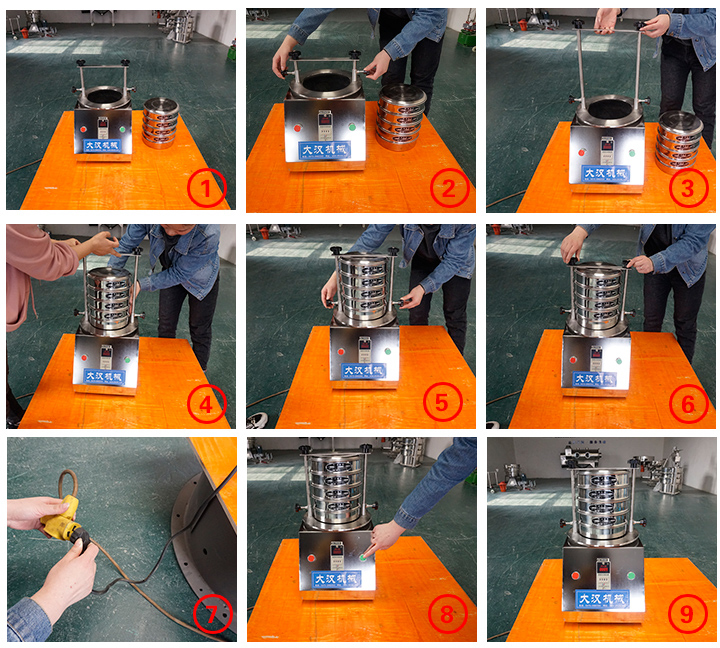

How to use standard test sieve?

Standard test sieves are widely used in scientific research and production departments, laboratories, and quality inspection rooms in metallurgy, chemical industry, medicine, building materials, geology, national defense and other industries. They are used for vibration screening, filtration, and standard test detection of particle size structure, liquid solid content, and impurity content of granular and powdery materials.

Standard test sieve supplier

During the manufacturing process of our standard test sieves, DaHan Machinery, as an experienced manufacturer, ensures that the sieve mesh undergoes precise calibration to guarantee extremely narrow aperture size tolerances, ensuring the repeatability and comparability of test results. Each sieve is permanently marked with its mesh size, wire diameter, applicable standard, and unique serial number for easy traceability and quality control. The frame is polished or electrochemically treated to create a smooth, corner-free, and easy-to-clean surface, preventing sample residue. In addition to the above-mentioned high-quality manufacturing processes, the manufacturer also supports non-standard customized equipment, enabling the testing and sieving of various materials.

Standard Test Sieve Application Cases

In building material quality control, a cement plant uses a standard test sieve set with a diameter of 200mm, combined with sieves of 4.75mm, 2.36mm, and 1.18mm apertures, and an electric vibrating screen to sieve for 5 minutes to perform particle size analysis on incoming sand and gravel. The residue rate was 12%, meeting the requirements of GB/T 14684-2022 standard, confirming that this batch of sand and gravel is of qualified quality. In the food processing industry, flour companies commonly use 80-mesh and 100-mesh test sieves to test the fineness of flour, ensuring that the flour does not clump and has uniform particles, meeting the process standards for baking production.

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.