Cement clinker Vibrating Screen

Cement clinker Vibrating Screen is used in the screening of cement clinker, offering a wide range of processing capacities. Different models can process 30 to 200 tons of material per hour, with large, customized units capable of reaching approximately 600 tons per hour. Suitable for small to large cement production lines, it can screen particle sizes up to 5mm, with a stable clinker throughput of over 96%, meeting the particle size requirements of cement production.

The Cement clinker vibrating screen can handle clinker with a particle size not exceeding 100mm and can be directly connected to the discharge port of fine crushing equipment. It operates stably even with high-temperature and high-hardness materials. Installation is flexible; it can be placed before the cement mill, above the packaging silo, or suspended under the floor slab, requiring minimal space and easily integrating with existing production lines. Clear operating conditions are required, with vibration acceleration controlled below 20G. It is compatible with three-phase 380V power and can be integrated into the production process from crushing and grinding to packaging. The screen structure can be single-layered or multi-layered, completing grading and impurity separation in one pass. Screen area is available from 0.9㎡ to 4.5㎡, and adjustments can be made to accommodate different production demands.

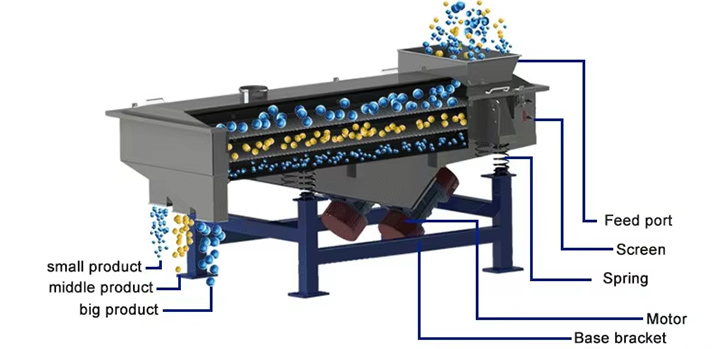

Cement Clinker Vibrating Screen Components

The component configuration of the Cement Clinker Vibrating Screen is tailored to the actual usage conditions during clinker screening. The screen surface is mostly made of high-manganese steel woven mesh, with mesh size adjustable from 1–50mm as needed. Some models use a polyurethane-coated stainless steel slatted structure, striking a balance between wear resistance and screening fineness. The high-manganese steel material can withstand the impact of falling clinker, resulting in a longer service life. The screen frame and body are generally made of high-strength carbon steel or heat-resistant alloy steel. The side plates are connected by high-strength bolts, making the structure more stable and less prone to deformation under high-temperature clinker conditions. The equipment is typically equipped with rubber shock-absorbing pads and springs. The rubber pads are installed at the contact points between the equipment and the hopper, serving both vibration isolation and dust prevention. The springs buffer vibrations during operation, and, in conjunction with anti-reverse nuts and spring washers, reduce loosening after prolonged operation.

Cement Clinker Vibrating Screen Functions

The Cement Clinker Vibrating Screen exhibits stable high-temperature resistance. Key load-bearing components are made of heat-resistant alloy steel and have undergone anti-oxidation treatment, allowing for continuous operation even at high cement clinker temperatures. It can operate normally when the workshop ambient temperature is controlled below 40℃, and its operation will not be affected by fluctuations in incoming material temperature. To reduce screen clogging, the equipment incorporates an elastic ball screen cleaning structure, coupled with high-frequency, low-amplitude vibration. The elastic balls continuously tap the screen during operation, reducing particle jamming. The arc-shaped screen surface allows for faster dispersion of cement clinker, preventing accumulation. Structurally, the screen surface and frame use a low-stress connection, combined with rubber pads and spring shock-absorbing components, to buffer the impact of falling cement clinker and reduce wear and tear from long-term operation. The equipment supports continuous operation, with bearing operating temperatures not exceeding 95℃, making it suitable for all-weather operation and reducing downtime due to screen cleaning. Safety features are also well-considered, with a protective net at the feed inlet to prevent tools or debris from falling in. The vibrating motor has a clamping device during transport, and the overall enclosed structure reduces dust leakage, ensuring safer operation.

Cement Clinker Vibrating Screen for Sale

The price of a Cement Clinker Vibrating Screen is influenced by various factors, such as the equipment model, size, number of screen layers, material configuration, and the manufacturer's processing capabilities. Generally, small or standard configuration single-layer vibrating screens have a relatively simple structure, with prices ranging from $2,600 to $7,000, suitable for small to medium-sized cement plants or partial upgrades of older production lines. Larger, more complex models with higher wear and heat resistance requirements will naturally have higher costs, typically ranging from $9,000 to $12,000. For example, a linear vibrating screen with a processing capacity of over 200 tons per hour, equipped with a double-layer screen and an automatic lubrication system, typically costs around $15,000.

Cement Clinker Vibrating Screen Application Scenarios

Cement clinker vibrating screens are commonly used in cement production processes, primarily for screening clinker after crushing. They are generally installed between the fine crusher and the cement mill to screen out clinker particles larger than 5mm, which are then sent back to the crushing process. This results in more uniform particle size of the material entering the cement mill, smoother mill operation, and increased output. Besides clinker screening, it is also useful in the raw material preparation stage for grading raw materials, separating non-compliant cement particles in advance to reduce the burden on subsequent processes. Before finished product packaging, this equipment is often installed above the packaging silo to screen out lumps or mixed impurities, preventing interference with packaging equipment operation and ensuring a more stable finished product condition. In addition, it can also perform screening and grading in the processing of building materials such as limestone and sand. A single unit can be used in multiple processes, making it suitable for the production needs of cement plants, clinker production lines, and building material processing sites.

The Cement clinker vibrating screen is a common screening device in cement production processes. It has a wide adjustable capacity, stable screening effect, and a robust structure, capable of withstanding high temperatures, high dust levels, and continuous operation. The equipment is made with materials that prioritize heat resistance, impact resistance, and wear resistance. The screen and vibrating components are designed to prevent clogging, reduce vibration, and withstand long-term operation. By controlling the clinker particle size, subsequent cement grinding operations are smoother, and the mill's workload is reduced. The equipment is available in various models covering different capacity ranges, with a wide price range. It integrates seamlessly with existing production lines and can be used interchangeably for screening clinker, raw materials, finished cement, and other building material raw materials.

-

Double deck with incline vibrating screen

Double deck with incline vibrating screen adopts high-quality wear-resistant screen mesh and high-strength steel structure.

-

Liquid vibratory sifter is a device used to separate solid particles from liquid.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Raw sesame is often mixed with soil, sand, metal chips, glass fragments, etc. These impurities not only affect the taste.

-

Wood Chip Vibrating Screen

Wood Chip Vibrating Screen separates wood chips of different sizes while removing impurities such as stones, twigs, and fragments...

-

Activated Carbon Screening Machine

Activated Carbon Screening Machine is a commonly used screening device in activated carbon production...

-

Plastic powder Screening Machine

Plastic powder Screening Machine is used in plastic processing and powder handling to classify, remove impurities...

-

Soybean Vibrating Screen

Soybean Vibrating Screens are widely used in soybean processing...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.