Sieving Machine For PET Recycling Plant

What is Sieving Machine For PET Recycling Plant?

The sieving machine for PET recycling plant is a key equipment for separating and classifying different particle sizes or partitions. In the plastic recycling process, it mainly processes polyethylene terephthalate raw materials, and common sources include discarded beverage bottles, food packaging, etc. that have been processed by equipment such as pulverizers. After the raw materials are crushed and cleaned, they need to be screened by selecting a suitable sieving machine to remove impurities, classify particle sizes, and improve the efficiency and quality of subsequent granulation or reuse.

Screening machine output typically depends on the model and screen size. Smaller machines have a processing capacity of approximately 300-800 kg/hour, while larger, more efficient screeners can reach 2-4 tons/hour or even higher. During the screening process, multi-layer vibrating screens or drum screens simultaneously separate coarse, medium, and fine PET flakes for subsequent melt pelletization or direct reuse.

What are the classifications of sieving machine for PET recycling plant?

Sieving Machine For PET Recycling Plant mainly includes three types: drum screen, linear vibrating screen and rotary vibrating screen. The drum screen is suitable for the preliminary sorting of large particles and those containing more impurities. It has the characteristics of large processing capacity and is not easy to be blocked; the linear vibrating screen is suitable for the detailed classification of the crushed PET fragments and has high screening accuracy; the rotary vibrating screen has a compact structure and is mostly used for the screening of fine powders or tiny particles. It is suitable for the further processing of PET fine materials. Different screening machines are suitable for different links of the PET recycling process.

1. Drum screen

The screen of the drum screen is multi-layered and slightly tilted. The screen drum automatically slides and rotates around the axis, and the horizontal material is graded through the screen during rolling. The material enters from the feed port, and the rotation drives the material to roll and slide. Under the action of gravity, the material of different particle sizes is screened, and it also has a certain dehydration function. Sieving machine for PET recycling plant in PET recycling, screening is used for pre-screening before material crushing. Its screening form is rolling screening, with large feed volume, high screening output, and strong processing capacity (single machine capacity can reach 50-300 tons/hour), which is particularly suitable for large-scale PET recycling production lines.

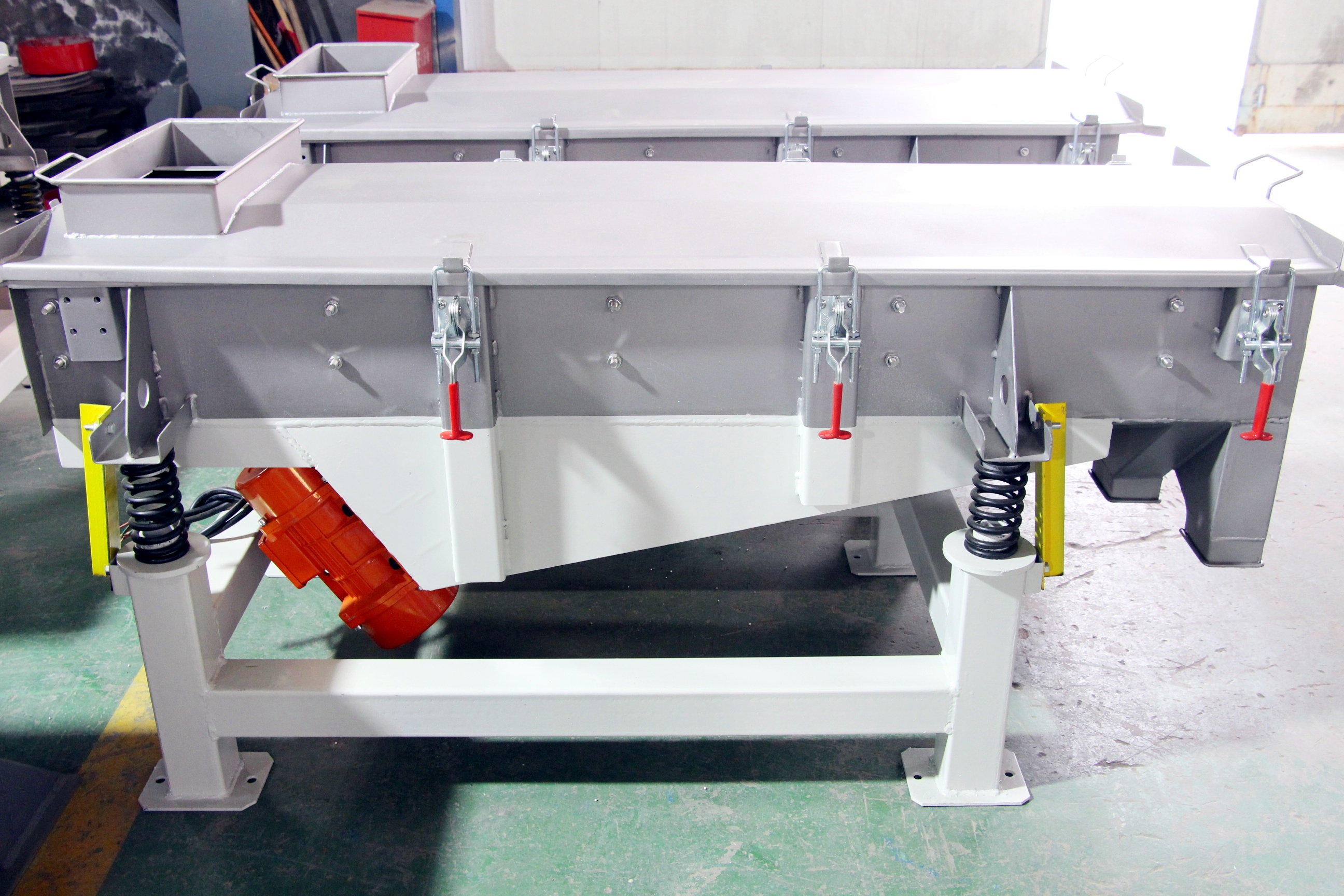

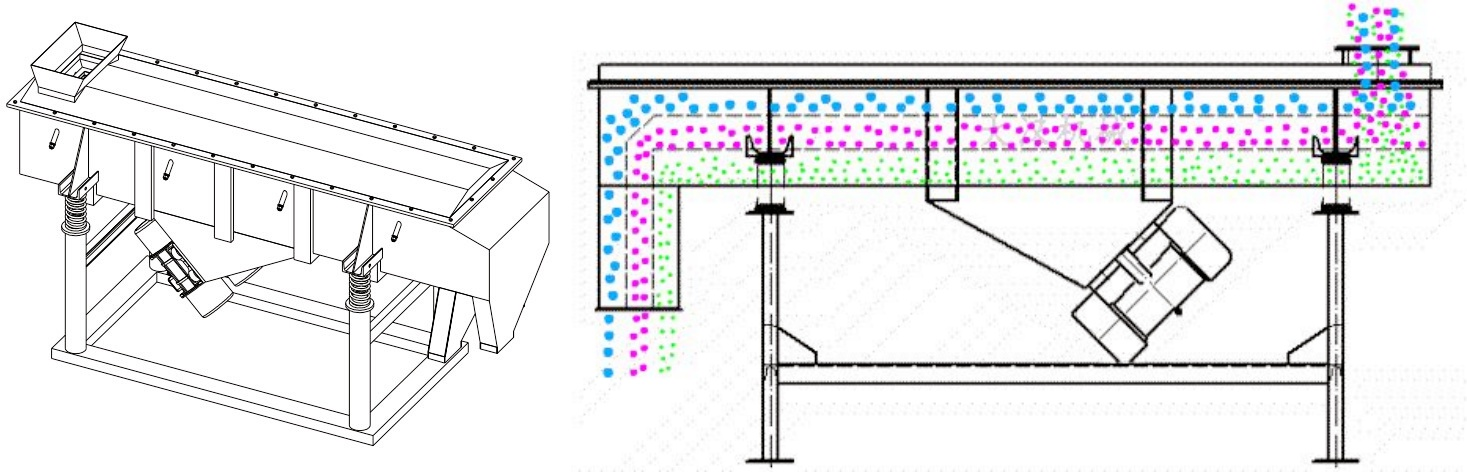

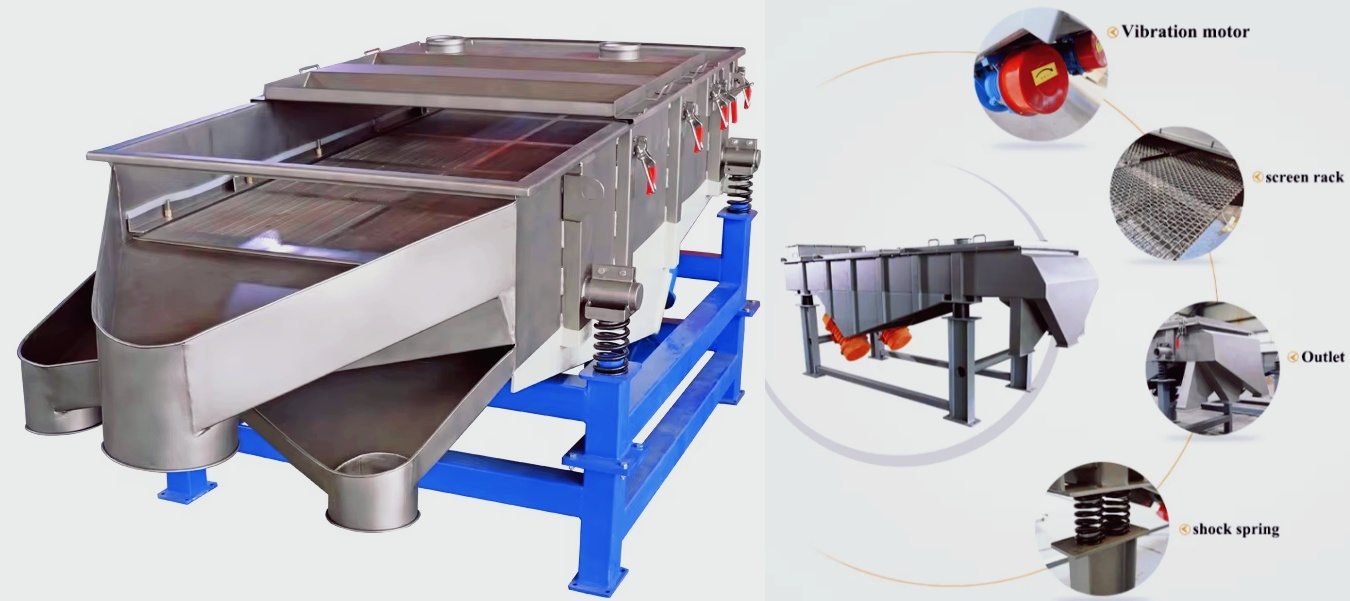

2. Linear vibrating screen

Sieving Machine For PET Recycling Plant Another commonly used screening equipment is linear vibrating screen.the linear vibrating screen is usually driven by dual motors and can be equipped with multi-layer screens to achieve multi-level particle size separation. The material jumps forward along the screen surface under the action of vibration and is graded layer by layer according to the particle size. It is mainly used for particle size classification of fragments after PET bottles are crushed, and can effectively screen out fine powder or oversized particles generated during the crushing process. Linear vibrating screens have a high screening capacity and are usually used for dry screening. They are also suitable for light wet materials. The screening capacity varies depending on the material characteristics and the size of the screen surface, usually ranging from 0.5 to 20 tons per hour.

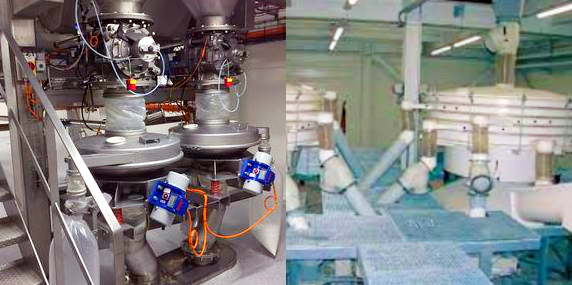

3. Rotary Vibrating Screen

The rotary vibrating screen generates three-dimensional composite vibrations through the upper and lower eccentric blocks of the motor, so that the material moves in a composite horizontal, vertical and inclined direction on the screen surface. 1 to 5 layers of screens can be installed to achieve multi-stage screening, which is suitable for high-precision screening of fine fragments and powders in the PET recycling process. The screening form is mainly dry screening, and it is also suitable for fine processing of small amounts of wet materials; high-frequency vibration promotes rapid stratification of materials, and materials of different particle sizes are discharged from the corresponding screen layers. Depending on the number of screen meshes, material properties and equipment diameter, the screening capacity is generally between 0.1 and 5 tons per hour.

What is the working principle of sieving machine for PET recycling plant?

The screening machine in the PET recycling plant is mainly used to separate and screen the recycled PET plastics for subsequent processing and reuse. Its working principle generally includes the following steps:

Feeding: Discarded PET bottles or other plastic materials are fed into the screening machine through a conveyor belt.

Screening: There are usually screens or screen plates of different sizes inside the screening machine, which are separated according to the size and shape of the plastic particles. Larger debris will be screened out, while PET plastics of the right size will continue to move forward.

Vibration: The sieving machine for PET recycling plant can use the vibration mechanism to make the material more evenly distributed on the screen, thereby improving the screening efficiency.

What are the advantages of the sieving machine for PET recycling plant?

High-precision sorting to improve the purity of raw materials: Through screens of different mesh sizes (such as 20-200 mesh), impurities such as labels, sand, unbroken bottle caps, fibers, etc. in PET fragments are removed step by step. The screening machine can ensure that the size of the crushed PET particles is uniform, avoiding the impact of too large or too small particles on the subsequent cleaning, granulation or melting process.

Improve recycling efficiency and reduce labor costs: The screening machine can run continuously for 24 hours, with a large processing capacity (such as the vibration screen can process up to 1-5 tons per hour), which greatly reduces the need for manual sorting. The sieving machine for PET recycling plant completes multi-level sorting at one time through the combined operation of coarse screening (20 mesh) + fine screening (80 mesh).

Reduce the waste of raw materials and improve economic benefits: through reasonable mesh screening (such as 60-80 mesh filtering and washing of fine impurities), reduce the mis-discharge of qualified PET fragments, and the recovery rate can reach more than 95%. The sieving machine for PET recycling plant can remove hard impurities in advance. Uniform particle size can improve granulation and melting efficiency.

Improve material purity: PET recycling plant screening machines can efficiently remove impurities in PET particles, such as paper scraps, metals, plastic fragments, etc., to ensure that the recycled PET materials are purer, which is conducive to subsequent processing and recycling.

Recommended mesh number of sieving machine for PET recycling plant

|

Purpose |

Recommended mesh number of screen |

Scope of application |

|

Screening of coarse particles |

10-20 mesh |

Used to remove large particles, such as large plastic pieces, paper scraps and other impurities |

|

Screening of medium and fine particles |

30-50 mesh |

Used to screen medium-sized particles and remove large plastics or impurities |

|

Screening of fine particles |

60-100 mesh |

Used for screening fine particles, suitable for screening small plastic fragments, fibers, etc. |

|

Screening of ultra-fine particles |

120-200 mesh |

Used for screening finer particles, suitable for plastic powder and fine impurities |

What is the role of sieving machine for PET recycling plant?

The application of sieving machine for PET recycling plant runs through the core links of the entire recycling process. Its value is reflected in improving recycling efficiency, ensuring the quality of recycled materials and promoting environmentally friendly production. It is mainly used for grading, removing impurities, color separation and homogenization of crushed PET fragments to ensure that the quality of recycled materials meets the requirements of subsequent processing.

Impurity separation: Through the difference in screen aperture, large impurities (such as bottle caps, labels, metal fragments) and small particle pollutants (such as sand and glass) in PET waste are removed to improve the purity and quality of PET.

Particle size standardization: Classify the crushed PET fragments by particle size (such as 3-8mm, 8-12mm) to adapt to different recycling process requirements:

Small particle size (<5mm): used to produce fibers and films.

Medium particle size (5-12mm): suitable for granulation and wire drawing.

Large particle size (>12mm): may need to be returned to the crusher for further processing.

Reducing energy consumption: Standardized particle size can optimize the melt extrusion process and reduce energy consumption by 10-15%

Sieving Machine For PET Recycling Plant Customer Case

A screening machine has been installed at a plastic recycling plant to grade bottle flakes after washing. This equipment separates PET flakes of varying sizes and impurities, improving the efficiency of downstream washing and re-pelletizing processes. The multi-layered screen structure significantly enhances screening accuracy, effectively removing unwashed residues and metallic impurities. Customers report that the addition of the screening machine has increased production on the entire recycling line by 30% and significantly improved the purity of the finished product.

A large PET plastic recycling company needed to process mixed-size waste bottle flakes and remove impurities such as sand and label residue. Traditional vibrating screens were prone to clogging, had a processing capacity of less than 2 tons/hour, and exhibited low sorting accuracy. Our company's multi-layer drum screening machine utilizes three layers of stainless steel screens and is equipped with a brush and air injection system. This increases processing capacity to 5 tons/hour and reduces energy consumption by 30%. Ultimately, it achieved a 98% impurity removal rate.

The selection of a suitable screening machine should be determined based on the specific process flow of PET recycling, the processing volume requirements, the impurity content of the raw materials, and the quality standards of the final product. The sieving machine for PET recycling plant is an indispensable key equipment to ensure the efficient and stable operation of the recycling process and ultimately produce high-quality recycled PET products. It improves product quality and promotes the recycling of resources by removing various impurities. Usually, a PET recycling plant will use a combination of multiple types of screening machines to achieve the best separation effect.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Granules, powders, and paddle materials can be used.

-

Meet the needs of large-scale and high-precision screening

-

Why use gas protection ultrasonic sieving machine metal powder?

The specific gravity of metal powder is light and easy to Due to static electricity problem, it is difficult for general vibrating screen to screen effectively ...

-

How much is an abrasive automatic sieving machine?

Abrasive automatic sieving machine is a commonly used industrial powder sieving equipment, widely used in metallurgy...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification...

-

Tea seed grading linear vibrating screen

The tea seed grading linear vibrating screen is a key equipment used in the tea processing field for screening...

-

EAA polymer powder sieving machine

EAA polymer powder sieving machine is an automated equipment designed for high-precision sorting, ensuring that...

-

Dry Material Silica Powder Screening Machine

The dry material silicon powder screening machine is a vibrating screen device used for efficient screening and...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.