Dry Material Silica Powder Screening Machine

What is a dry material silicon powder screening machine?

The dry material silicon powder screening machine is a vibrating screen device used for efficient screening and grading of dry silicon powder. It is suitable for grading or removing impurities of granular and powdered dry materials. It is driven by a dual vibration motor to make the material jump forward on the screen surface in a straight line, thereby realizing the separation of silicon powder of different particle sizes. The mesh number of the screen is generally between 20 mesh and 325 mesh, which is suitable for screening silicon powder with a particle size range of 45μm to 0.85mm. The equipment supports 1 to 5 layers of screen configuration, with a processing capacity of up to 0.5-5 tons per hour, which is suitable for continuous production needs.

Applicable material characteristics

Material state: dry and good fluidity.

Particle size range: usually suitable for silicon powder within 80~500 mesh.

Impurity: The dry material silica powder screening machine can be used for impurity removal, such as screening out agglomerates, larger particles or foreign matter.

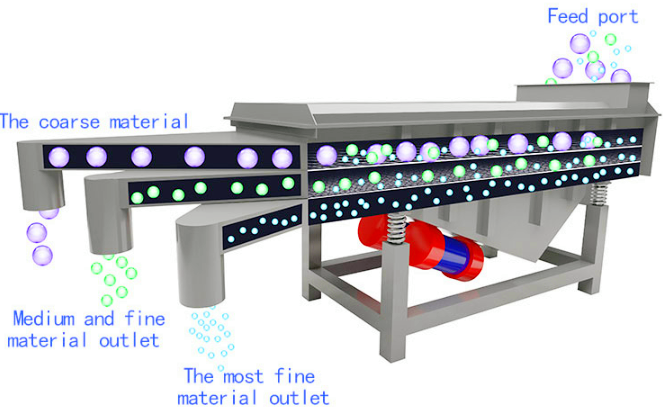

Working principle of dry material silica powder screening machine

Start the vibration motor and the screen box starts to vibrate. The silicon powder is fed into the screen surface and, under the action of the vibration force, makes a linear jumping motion on the screen surface. Materials of different particle sizes are graded according to the mesh size. Materials smaller than the mesh pass through the mesh and become under-mesh materials; materials larger than the mesh move forward along the mesh surface and become over-mesh materials; after the grading is completed, they are discharged from different outlets.

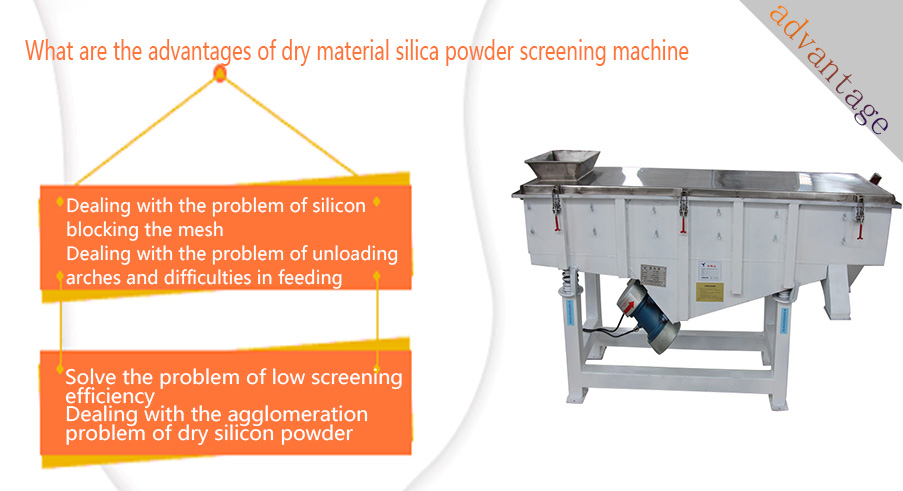

What are the advantages of dry material silica powder screening machine

Dealing with the problem of silicon blocking the mesh: The powder particles are fine and irregular in shape, and are easily stuck in the mesh holes, causing blockage. The screening machine uses a vibration motor to excite the material to make the material move in a jumping linear motion in the mesh, promote the material to pass through the mesh quickly, and reduce siltation. The dry material silica powder screening machine uses a multi-layer screen suitable for the powder particle size (usually 1-4 layers can be equipped), and uses a screen material with a high opening rate.

Dealing with the problem of unloading arches and difficulties in feeding: Silicon powder may form a material arch due to collision or electrostatic action of internal particles, resulting in poor feeding. The linear screening machine optimizes the movement trajectory of the material on the screen surface by adjusting the angle or amplitude of the eccentric block of the vibration motor, destroys the material arch, and promotes loading and unloading. Equipped with uniform feeding device (such as vibrating feeder) to avoid overfeeding and siltation in the silo.

Solve the problem of low screening efficiency: In order to improve the screening efficiency of dry silicon powder, the dry material silica powder screening machine adopts a graded screen design, which can select 2-5 particle sizes at the same time to meet different particle size requirements. The vibration frequency and adjustable number of the equipment adjust the screening characteristics of silicon powder to ensure high particle size processing. Some equipment enhances the fluidity of the material by loosening tension, quickly separates large particles or small particles, and improves the classification accuracy and efficiency.

Dealing with the agglomeration problem of dry silicon powder: The dry material silica powder screening machine generates high-frequency linear vibration through a dual vibration motor, forcing the material to jump quickly on the screen surface and move forward. This movement mode can effectively break the agglomeration of silicon powder, and at the same time screen it step by step through multiple layers of screens (usually 2-5 layers). The screen surface inclination and vibration intensity can be flexibly adjusted according to the material characteristics (such as particle size, humidity) to avoid material accumulation or insufficient screening.

Recommended mesh number of dry material silica powder screening machine

|

Silicon powder type |

Typical particle size range |

Recommended mesh number |

Application scenario |

|

Coarse particle silicon powder |

100μm~500μm |

30 mesh~100 mesh |

Primary impurity removal of photovoltaic silicon materials |

|

Medium fineness silicon powder |

45μm~150μm |

100 mesh~325 mesh |

Grading of negative electrode materials for lithium batteries |

|

Ultrafine silicon powder |

10μm~45μm |

325 mesh~600 mesh |

Fine screening of high-purity electronic grade silicon powder |

|

Nano silicon powder |

<10μm |

Need air flow screen or ultrasonic vibration screen |

Nano material field (linear screen is not applicable) |

Application field of dry material silica powder screening machine

Dry material silica powder screening machine is not only suitable for dry silicon powder, but also for screening of similar materials such as quartz sand, silicon carbide, metal powder, etc., especially in photovoltaic silicon materials, lithium battery materials, ceramic powders and other high-precision fields. It is widely used in silicon material production, semiconductor material preparation and related industries. For example, in the metal silicon powder crushing and screening production line, the linear screening machine can achieve high-capacity and high-precision screening effects for silicon powder.

Screening of dry silicon powder

Non-metallic minerals such as quartz sand, talcum powder, and graphite powder

Chemical powder materials

Refractory materials such as silicon carbide and alumina

As a light, fine, and dusty powder raw material, dry silicon powder places high demands on screening equipment. With its fully enclosed structure, strong vibration source, multi-layer grading screen surface and anti-static design, the dry material silicon powder screening machine can better solve the problems of dust leakage, screen blockage, and low screening efficiency. It is suitable for use in silicon powder grading in fine chemicals, photovoltaics, electronics and other fields.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Granules, powders, and paddle materials can be used.

-

Meet the needs of large-scale and high-precision screening

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification...

-

Tea seed grading linear vibrating screen

The tea seed grading linear vibrating screen is a key equipment used in the tea processing field for screening...

-

EAA polymer powder sieving machine

EAA polymer powder sieving machine is an automated equipment designed for high-precision sorting, ensuring that...

-

Seating Machine For Stone Ground Flour

Seating machine for stone ground flour is a device used to screen flour in the process of stone ground flour production.

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.