EAA Polymer Powder Sieving Machine

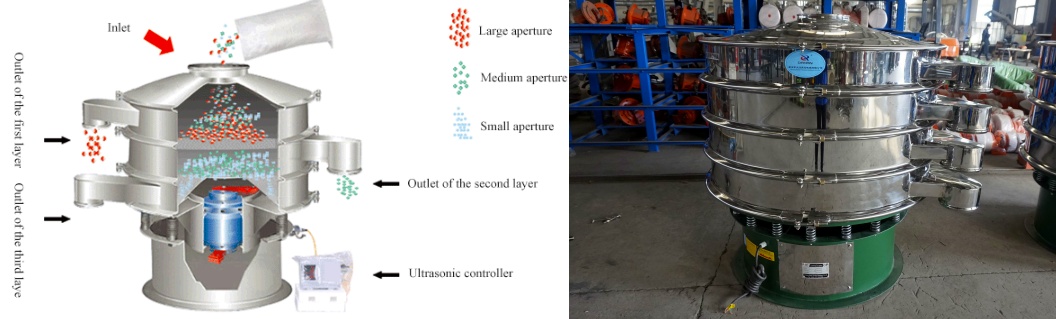

EAA polymer powder sieving machine is an automated equipment designed for high-precision sorting, ensuring that the EAA polymer powder has uniform particle size and is free of impurities. It is suitable for the fields of electronics, medicine and special materials. EAA Polymer Powder Sieving Machine adopts a multi-layer vibrating screen structure to achieve multi-level sorting, improve the screening efficiency by more than 30%, and the screening mesh range covers 80-800 mesh, which can accurately adapt to the EAA powder classification with different particle size requirements. The sieve body is made of 304 stainless steel and equipped with a food-grade silicone sealing ring to ensure that the material is contaminated.

EAA Polymer Powder Sieving Machines offer options for sieve mesh sizes. Vibrating sieves range from 20 to 500 mesh. For smaller sieve sizes, test sieves can be selected to provide accurate particle size measurement standards. For coarse particles, linear vibrating sieves with sieve mesh sizes from 20 to 200 mesh can be selected, and materials such as stainless steel, special coatings, or plastics can be chosen.

EAA polymer powder sieving machine video

What are the benefits of an EAA Polymer Powder Sieving Machine?

EAA can be separated from mechanical impurities or trace contaminants that may be introduced during the production process. The EAA Polymer Powder Sieving Machine improves product purity through sieving. If EAA needs to be mixed with other additives, pre-sieving can make the mixing more uniform and avoid stratification due to particle differences. EAA powder has a certain degree of flammability, and the closed sieving equipment can effectively suppress dust emission and reduce the risk of explosion. The uniform powder particle size obtained by the equipment can improve melt flowability, reduce material blockage and fluctuations in extrusion, coating or lamination processes, and enhance process controllability.

EAA Polymer Powder Sieving Machine Parameters

The EAA polymer powder sieving machine can be selected based on the required sieving particle size and sieving output. The following are the relevant parameters of the equipment, such as diameter, feed size, and sieving capacity, which can be matched and selected.

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

What is the working principle of EAA polymer powder sieving machine?

The EAA polymer powder sieving machine uses a vibrating motor to generate vibration, causing the entire machine to rotate and vibrate at high frequency, which in turn causes the screen to shake. After the EAA powder enters through the feed inlet, it gradually disperses under the vibration, breaking up any clumps of powder that were previously stuck together. Fine powder passes through the small holes in the screen and falls to the bottom for collection; larger particles or impurities cannot pass through the screen holes and move along the screen surface, eventually exiting from the outlet on the other side. Different screen sizes can be used depending on the required powder coarseness. The vibration frequency, amplitude, screen type, and the characteristics of the material itself will affect the sieving effect of the EAA powder.

Recommended mesh number of EAA polymer powder sieving machine

The EAA Polymer Powder Sieving Machine can separate coarse, fine, or ultrafine particles according to the required sieving mesh size for different materials. Below are recommended mesh sizes and applicable scenarios for different particle size ranges.

The mesh size of the EAA polymer powder sieving machine can be selected according to the application scenario. Coarse sieving can use 80 to 200 mesh, with particle sizes between 180 microns and 74 microns, suitable for pre-screening raw materials to remove large particles and agglomerates, and also meets the needs of general processing such as injection molding and extrusion. Fine sieving uses 200 to 400 mesh, with particle sizes between 74 microns and 38 microns, suitable for electronic packaging, film coating, and powder classification of pharmaceutical excipients and sustained-release carriers. Ultrafine sieving uses 400 to 800 mesh, and can be customized down to 1200 mesh, with particle sizes from 38 microns to 15 microns, and customized models down to 5 microns, mainly used for special coatings, nanomaterials, electronic pastes, and 3D printing powders.

What are the disadvantages of the EAA polymer powder sieving machine?

EAA polymer powder sieving machines have relatively small sieve openings, causing powder to easily scatter during vibration, resulting in particle loss and reduced finished product output. It's advisable to first use a sieve with larger openings for coarse sieving to reduce powder waste, followed by fine sieving. This type of powder is prone to generating static electricity after friction, which can cause it to stick to the sieve mesh, affecting sieving efficiency. Proper grounding of the equipment or using an anti-static model can alleviate this. The machine operates at a high vibration frequency, resulting in relatively loud noise; selecting a model with vibration isolation and noise reduction designs would be more suitable. Furthermore, the finer the sieve, such as above 200 mesh, the slower the powder passes through, reducing output. Using multiple layers of sieves to separate coarse and fine powders in stages can improve this situation.

What is the application of EAA polymer powder screening machine?

EAA Polymer Powder Sieving Machine ensures uniform particle size of EAA raw material powder, providing a processing basis for hot melt adhesives, coatings, packaging materials and other products; intercepts lumps or impurities, ensuring smooth extrusion, injection molding and other processes and product quality; it is also used for the classification of finished powder at the end of the production process.

Packaging material production: EAA powder needs to have a uniform particle size to ensure coating consistency and bonding strength. The sieving machine often uses a 100-150 mesh screen to sieve out powder with a particle size of 0.1-0.15mm and remove oversized particles or agglomerates. For example, in the production of multi-layer co-extruded films, the sieved EAA powder ensures the stability of the film layer's heat sealing performance and improves the sealing of the packaging.

Cable shielding material: EAA powder is used for bonding and filling of cable shielding layers, requiring high purity and fine particle size to ensure electrical performance. The sieving mesh number recommendation of EAA polymer powder sieving machine needs to be determined according to its specific application field and the required final product particle size. EAA powder is widely used, and different applications have different requirements for the fineness and uniformity of the powder. Use a sieve of 200 mesh or more to screen out ultrafine powder with a particle size of less than 0.075mm to remove impurities and irregular particles.

Hot melt adhesive manufacturing: EAA powder is an important raw material for hot melt adhesives, and the particle size needs to be strictly controlled to ensure uniform melting and coating effect. The sieving machine is usually equipped with an 80-120 mesh screen to sieve out powder with a particle size of 0.125-0.18mm, which is suitable for scenes such as automotive interiors and textile bonding. The sieving process removes overly fine or coarse particles and improves the construction performance of the adhesive.

Powder coating: EAA powder needs to be fine and evenly distributed to ensure smooth coating and adhesion. The sieving mesh number recommendation of the EAA polymer powder sieving machine needs to be determined according to its specific application field and the required final product particle size. EAA powder is widely used, and different applications have different requirements for the fineness and uniformity of the powder. Using a 150-200 mesh screen, the powder with a particle size of 0.075-0.1mm is widely used in metal surface anti-corrosion coatings.

3D printing material preparation: In the field of additive manufacturing, EAA powder, as a 3D printing consumable, requires extremely high particle size consistency. The sieving machine uses a 250-325 mesh screen to screen out ultrafine powders with a particle size of less than 0.045mm, ensuring good powder fluidity during printing and tight interlayer bonding, which is suitable for precision parts manufacturing.

Selection suggestions

When selecting an EAA Polymer Powder Sieving Machine, factors such as the material and non-stick properties of the equipment, whether the machine can be sealed and its dust removal function, screening efficiency and output, and ease of cleaning and maintenance should be considered. The following are detailed suggestions for reference.

When selecting an EAA polymer powder sieving machine, first calculate the amount of powder to be processed per hour or per day, then determine the appropriate model and size. EAA powder itself has poor flowability, so appropriate vibration methods or auxiliary accessories can be used during sieving to make the process smoother. Common types include circular vibrating screens, linear vibrating screens, ultrasonic vibrating screens, and air classifiers; choose according to your specific needs. Also, consider the screen mesh count, material, number of screen layers, vibration frequency, and amplitude. The equipment material can be carbon steel or stainless steel, and the inlet and outlet should be easily compatible with the production line. Additionally, pay attention to the ease of daily maintenance and understand the supplier's after-sales service to avoid problems later on.

EAA Polymer Powder Sieving Machine Solution

The EAA Polymer Powder Sieving Machine meets the requirements of both indoor production and outdoor environments. Designed to handle diverse material characteristics, including electrostatic aggregation, hygroscopicity, high fineness, and high abrasiveness, this machine integrates multiple functions. For lightweight, fluffy powders, it employs airflow sieving technology; for easily agglomerated materials, it features ultrasonic screen cleaning and a bouncing ball anti-clogging device; for high-precision applications, it offers multi-layer precision grading; and it is equipped with a fully enclosed structure to prevent contamination and dust escape, achieving end-to-end adaptability from raw material characteristics to sieving targets.

In general, EAA polymer powder sieving machine has a compact structure, simple operation, easy maintenance and cleaning. The fully enclosed design effectively prevents dust from flying and meets environmental protection requirements. The sturdy and durable material ensures the long-term stable operation of the equipment, which is an ideal choice for EAA polymer powder production and application fields. The processing capacity can reach 50-200 kg per hour, and the specific output depends on the material characteristics and sieve mesh.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Powder sieving machine is designed for high volume sieving of powders to remove oversized contaminants ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical and chemical properties of...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification, impurity removal or particle...

-

Powder Sieve Machine Price

Powder Sieve Machine Price varies depending on the specifications, and the market quotation is usually between US$500 and US$8000...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.