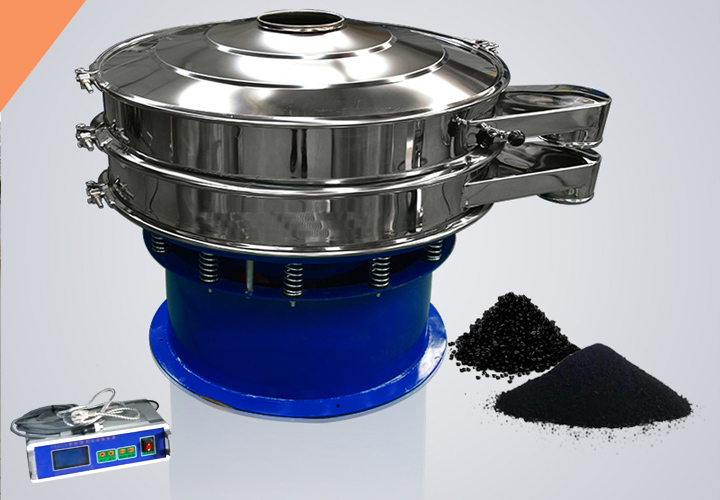

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine can solve problems such as material agglomeration, uneven particle size, and impurity removal. Their sieving mesh size typically ranges from 20 to 500 mesh, and the output range depends on the size of the machine; small machines produce approximately 50-200 kg/hour, while large industrial machines can reach 1-5 tons/hour or more.

TPU polymer powder is a polymer material with excellent elasticity, wear resistance, oil resistance and low temperature performance, which is widely used in 3D printing, coatings, footwear, medical devices and other fields. TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification, impurity removal or particle homogenization of TPU polymer powder. Its design features fully consider the physical and chemical properties of TPU powder. Its main function is to screen out substandard particles (too large or too small) to obtain TPU powder with more uniform particle size and purity.

TPU Polymer Powder Sieving Machine video

How does the TPU polymer powder sieving machine work?

The TPU Polymer Powder Sieving Machine uses a combination of mechanical and ultrasonic vibrations to separate TPU powder. During operation, the TPU powder is smoothly fed from the inlet onto the screen. A vibrating motor drives the screen in three-dimensional motion—horizontal, vertical, and inclined—causing the powder to disperse and move. Larger particles move towards the screen edges, while smaller particles initially pass downwards. Simultaneously, an ultrasonic generator emits a 20-40kHz high-frequency electrical signal, which is converted into vibrations on the screen by a transducer. Finally, according to the screen aperture size, fine powder passes through the screen and falls into the collection tray below, while coarse particles remain on the screen and are discharged from the outlet.

What are the advantages of the TPU polymer powder sieving machine?

The advantages of the TPU Polymer Powder Sieving Machine are that it can solve problems such as the softening of TPU polymer powder due to heat sensitivity, the easy agglomeration and sticking of powder to the sieve, the uneven particle size distribution of powder, the easy dispersion of powder and the difficulty in sieving. In addition, the closed operation of the equipment reduces the waste of raw materials and reduces manual operation.

Solve the problem of TPU polymer powder softening due to heat sensitivity: The glass transition temperature (Tg) of TPU is low (about -30℃~50℃), and the friction heat generated by screening may cause the particles to soften and stick together. The low-speed design is adopted to reduce the heat generated by mechanical friction. A water-cooled jacket or air-cooled device can be optionally equipped to control the screening temperature to <40℃.

Solve the problem of TPU polymer powder easily agglomerating and sticking to the screen: TPU has a certain viscosity and is easy to agglomerate under high humidity or temperature conditions. The powder sticks to the screen, affecting the screening efficiency. The TPU polymer powder sieving machine breaks the adhesion force through 20-38kHz high-frequency vibration.

Deal with the problem of uneven particle size distribution of TPU polymer powder: The traditional perforated screen has a large error (±10μm), which affects the batch consistency of 3D printing or medical powder. Use high-precision electroformed screens, laser-cut or electroformed screens, with an aperture error of ≤±2μm (such as 325 mesh/45μm screens).

Dealing with the problem of ultrafine powder (<50μm) flying and difficult to screen: Traditional vibrating screens have extremely low screening efficiency for <50μm powders (mesh penetration rate <30%), and are prone to dust pollution. Apply negative pressure under the screen to enhance the ability of ultrafine powder to penetrate the screen. Use a three-stage cascade screen of 20 mesh → 100 mesh → 325 mesh to gradually grade and improve efficiency.

TPU Polymer Powder Sieving Machine Specifications

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Recommended mesh number of TPU polymer powder sieving machine

The TPU Polymer Powder Sieving Machine can sieve coarse, medium-sized, and fine powders. Below are recommended mesh sizes for powders of different particle sizes, from coarse to fine. You can refer to the following mesh sizes for effective sieving of TPU polymer powder.

Coarse screen (100-150 mesh): used for preliminary screening to remove large particles of impurities or agglomerates, you can use a lower mesh number, such as 20 mesh to 60 mesh, suitable for industrial parts, shoe materials and other scenes with low precision requirements.

Medium screen (150-250 mesh): for general powder classification, you can use 150 mesh to 250 mesh. Suitable for coating, shoe materials or recycling scenarios, balancing particle size uniformity and production efficiency.

Fine sieve (250-400 mesh): 200 mesh or even higher is required for screening very fine powders. TPU powder can even pass through a 325 mesh (44 micron) sieve, which is used in high-precision scenarios such as 3D printing and medical treatment to ensure fine particle size and high-quality surface.

Comparison between TPU polymer powder sieving machine and traditional sieving equipment

|

Comparison items |

TPU polymer powder sieving machine |

Traditional sieving equipment |

|

Image |

|

|

|

Screening principle |

Ultrasonic vibration, elastic ball net cleaning and other anti-sticking technologies |

Pure mechanical vibration (motor driven eccentric block) |

|

Applicable particle size range |

20μm~500μm (can screen ultrafine powder) |

75μm~5mm (fine powder is easy to block the net) |

|

Electrostatic control |

Stainless steel 316L/conductive coating, reduce electrostatic adsorption |

Ordinary carbon steel, easy to generate static electricity |

|

Applicable scenarios |

High-precision requirements (3D printing, medical, electronics) |

Coarse screening, general industrial use |

|

Typical models |

Ultrasonic vibration screen |

Rotary vibration screen, linear screen |

What can TPU polymer powder sieving machine be used for?

TPU Polymer Powder Sieving Machines are used for particle size screening of TPU powder in various industries. In coating and adhesive production, it separates powders into appropriately sized particles, resulting in smoother and stronger coating application and more uniform adhesive performance. In 3D printing, it removes particles that are too large or too small, making the printing process smoother and producing parts with more stable density, strength, and surface finish. In the production of elastomers and seals, sieved powder mixes more evenly during melting and extrusion, leading to more stable product performance. The cosmetics and pharmaceutical industries have high requirements for powder purity and particle size; this equipment removes impurities and separates TPU powder that meets the required specifications.

TPU Polymer Powder Sieving Machine Supplier

Suppliers of TPU Polymer Powder Sieving Machines are concentrated in Germany, the United States, and China. German suppliers are known for their precision technology, high-precision sieving, and automated systems, producing durable equipment. American suppliers excel in high-efficiency vibrating screens and large-scale industrial sieving solutions, with high levels of process integration. Chinese suppliers, such as Dahan Machinery, offer a wide range of machine models, can customize machines, and can conduct trial runs based on the customer's TPU powder particle size and flowability. They also provide fast service response, and their machines are sold worldwide.

TPU polymer powder sieving machine solves the problems of material viscoelasticity, static electricity and thermal sensitivity through targeted design, and is a key equipment to ensure powder quality. When selecting a model, it is necessary to comprehensively consider the particle size range, output and process environment to ensure screening efficiency and product consistency.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Graphite Powder Sieving Machine

Graphite powder sieving machine is specially developed to solve the problem of graphite powder sieving...

-

Ensures removal of contaminants such as large particles and agglomerates from metal powders, providing accurate particle size distribution

-

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

Desert sand sieving machine

Desert sand sieving machine is a mechanical equipment used for sand and gravel processing or sieving...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Dry Material Silica Powder Screening Machine

The dry material silicon powder screening machine is a vibrating screen device used for efficient screening and grading of dry silicon powder...

-

Screening Equipment DH-1000-2S

Screening equipment DH-1000-2S is a circular vibrating screening equipment with a diameter of 1000mm and two discharge ports...

-

Vibro Sifter Flour

The Vibro Sifter Flour uses a motor-driven eccentric weight to generate three-dimensional vibration...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.