Seating Machine For Stone Ground Flour

What is Seating Machine For Stone Ground Flour?

Seating machine for stone ground flour is used to finely grade ground whole wheat flour, removing coarse particles, bran, and impurities to achieve a fine and uniform flour, preserving the germ and nutrients. Utilizing multi-layer screens and vibration grading, the machine offers stable operation, high precision, and low energy consumption. Suitable for stone-ground flour mills and grain processing companies, the machine features an adjustable mesh size. Standard models have an hourly processing capacity of 500 kg to 2 tons, while larger models can reach over 3 tons. This machine effectively improves flour quality and is suitable for the production of whole wheat flour, cake flour, and specialty flours.

Seating machine for stone ground flour is a device used to screen flour in the process of stone ground flour production. Its main function is to finely screen the flour after stone grinding, remove coarse particles, bran, impurities, and separate flour of different particle sizes to ensure the fineness and quality of the finished flour. It is an important part of the stone ground flour production line, which aims to grade the flour after stone grinding according to particle size through screening, and remove bran and other impurities, so as to obtain flour products of different fineness.

Seating Machine For Stone Ground Flour Video Show

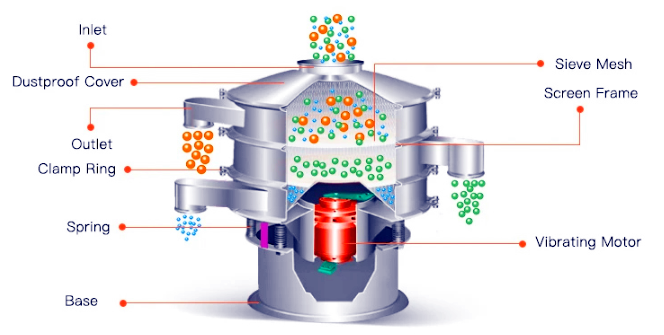

How does Seating Machine For Stone Ground Flour work?

Most seating machines for stone ground flour use a vibration motor to drive the screen, using vibration to make the flour particles jump on the screen surface, fine powder falls into the lower layer through the screen holes, and coarse powder moves along the screen surface to the outlet. The equipment is usually equipped with multiple layers of screens (such as 30 mesh, 60 mesh, 80 mesh, etc.), which can gradually screen out flour of different fineness, and the coarse particles can be returned to the stone mill for re-grinding.

Seating Machine For Stone Ground Flour parameters

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

What are the mesh sizes for sieving flour using Seating Machine For Stone Ground Flour?

Depending on the sieving requirements for stone-ground flour, the Stone Ground Flour Seating Machine requires different mesh sizes and equipment configurations for different materials and applications.

For granular materials, the sieving mesh size is generally lower, typically between 10-30 mesh, with a single machine output of 500-800 kg/hour. This is suitable for grading and removing impurities from granular materials such as sorghum and cornmeal.

The sieving mesh size for finely coarse powders typically ranges from 30-60 mesh, with an output of approximately 400-600 kg/hour. This is commonly used for products such as wheat flour and buckwheat flour that require a certain amount of coarse particles to be retained.

For small granular materials, the sieving mesh size is generally between 60-100 mesh, with an output of approximately 300-500 kg/hour. Common materials include sesame powder and rice flour, and are primarily used in the food processing and seasoning industries.

Fine flour typically has a sieving mesh range of 100-200, with a production capacity of 200-400 kg/hour. It boasts a high degree of fineness and is suitable for high-quality food ingredients such as refined wheat flour and pastry flour.

Ultrafine flour typically has a sieving mesh range of 200-400 or even higher, with a production capacity of approximately 100-300 kg/hour. It is suitable for applications requiring extremely high fineness, such as tea powder and medicinal herb powder.

Recommended mesh number of seating machine for stone ground flour

The stone-ground flour screening machine is specially designed for the fine processing of traditional stone-ground flour, and particle classification is achieved through multiple layers of vibrating screens (30 mesh, 60 mesh, 80 mesh, 100 mesh, etc.).

30-40 mesh screen retains bran and produces whole wheat flour; 60-80 mesh screens out general flour, suitable for steamed bread and noodles; 100-120 mesh screens can produce fine flour, which is used for cakes, dumpling wrappers, etc.

The role and importance of seating machine for stone ground flour

The characteristics of stone mill grinding are low temperature and low speed, which can retain the natural nutrients and original flavor of wheat. However, the flour ground by stone mill usually contains particles of different sizes and a certain amount of bran. In order to meet the market demand for flour for different purposes and improve the quality and taste of flour, the screening process is essential.

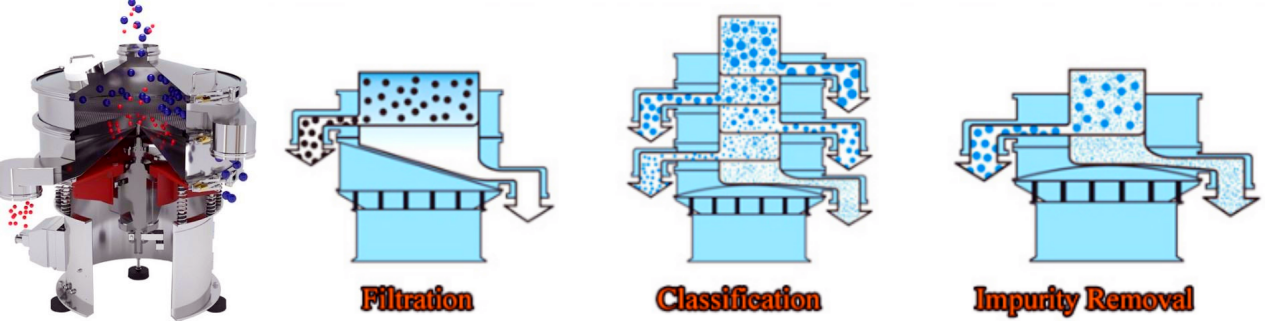

Grading: Separate the ground mixture according to different sieve apertures to obtain flour of different coarseness and fineness, such as whole wheat flour, refined flour of different grades, etc.

Removal of impurities: Seating machine for stone ground flour can effectively remove bran, germ fragments mixed in the flour, and other impurities that may be generated during the grinding process.

Improve the quality of stone-ground flour: Through precise screening, bran, impurities, stones, etc. in stone-ground flour can be removed, making the flour purer and better tasting, improving the quality and grade of flour, and meeting the needs of different users.

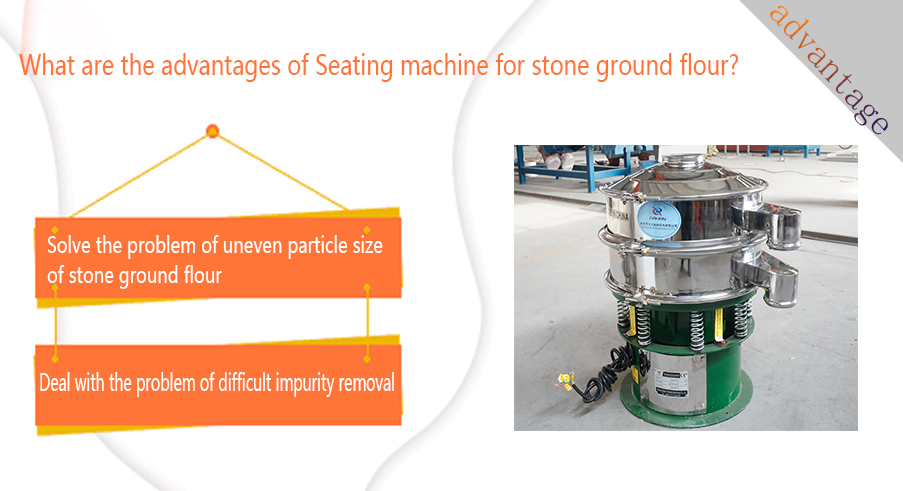

What are the advantages of Seating machine for stone ground flour?

Solve the problem of uneven particle size of stone ground flour: The screening machine is usually equipped with multiple layers of screens with different mesh sizes. When stone ground flour is screened, starting from the upper screen, larger particles are intercepted by the first layer of screen. As the flour moves on the screen, it gradually passes through screens with different mesh sizes and is screened into products of different particle size grades, thereby ensuring the uniformity of the size of flour particles.

Deal with the problem of difficult impurity removal: According to the type and size of impurities that may exist in stone ground flour, choose the appropriate screen material and structure. For example, for impurities such as fine sand particles, a stainless steel screen with a small aperture and a smooth surface can be used. Seating machine for stone ground flour can effectively intercept impurities while ensuring the normal passage of flour.

Application of seating machine for stone ground flour

The screening machine plays a key role in particle classification, impurity removal, quality control and bran separation in stone ground flour processing. Its application scenarios cover many fields such as traditional flour mills, high-end baking, handmade pasta, healthy food, organic food and catering supply chain. Through precise screening, the screening machine not only improves the quality and safety of stone ground flour, but also meets diverse market needs. In a typical stone ground flour production line, the screening machine is usually located after the stone mill. After pre-treatment such as cleaning and stone removal, the wheat enters the stone mill for grinding, and the ground material immediately enters the screening machine for processing. Depending on the production process and the type of flour required, one or more levels of screening may be set.

Effects in practical applications

In practical applications, the screening efficiency of stone ground flour can be significantly improved after using seating machine for stone ground flour. For example:

The impurity removal rate can reach more than 95%;

The screening rate is increased by 20%~30%;

The finished product fineness is controlled within the specified range (such as 80~120 mesh);

The screen blockage rate is reduced and the maintenance cost is reduced.

Seating machine for stone ground flour is a key equipment in the stone ground flour production line. Its main function is to grade the flour after stone grinding, remove bran, germ and other impurities, so as to obtain flour products of different fineness and grades. This equipment is generally used in flour mills, grain processing plants and other places to improve the purity and quality of flour. Choosing a suitable seating machine for stone ground flour requires comprehensive consideration of factors such as raw grain characteristics, expected flour yield and fineness. Reasonable screening process and high-performance screening equipment are important guarantees for the production of high-quality stone ground flour.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Granules, powders, and paddle materials can be used.

-

Meet the needs of large-scale and high-precision screening

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification...

-

Tea seed grading linear vibrating screen

The tea seed grading linear vibrating screen is a key equipment used in the tea processing field for screening...

-

EAA polymer powder sieving machine

EAA polymer powder sieving machine is an automated equipment designed for high-precision sorting, ensuring that...

-

LFP powder sieving machine

LFP powder sieving machine is a device specially used for grading and screening of lithium iron phosphate powder...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.