Linear vibratory Screen for Filtering Hibiscus

What is a linear vibratory screen for filtering hibiscus?

The linear vibratory screen for filtering hibiscus is generally a screening device with simple structure, stable operation and high screening accuracy to meet the needs of hibiscus in drying, screening, grading or impurity removal.

Hibiscus are often used as raw materials in the fields of medicinal materials, food or health products. The purpose of screening is to remove impurities, achieve size classification, or screen out non-target parts such as pedicels and leaves. Due to its light texture and brittleness, the screening process requires moderate vibration intensity to avoid petals from being damaged.

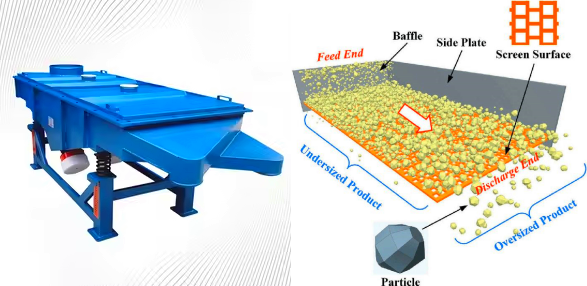

Working principle of linear vibratory screen for filtering hibiscus

① Vibration drive: Two vibration motors are symmetrically installed on both sides of the screen box, and a linear vibration trajectory is generated by synchronous reverse rotation.

② Material screening

Hibiscus fall evenly onto the screen surface from the feed inlet, and move linearly along the screen surface under the action of vibration: petals and fine particles that meet the screen aperture pass through the screen and become screened materials; larger impurities (such as branches) or materials that do not meet the requirements are discharged from the discharge port along the screen surface and become screened materials.

③ Multi-stage screening: Hibiscus are thrown up on the screen surface and move forward in a straight line. The materials are graded through multiple layers of screens (such as separating petals of different sizes), and materials of different specifications are discharged from their respective discharge ports, realizing multi-stage screening of materials.

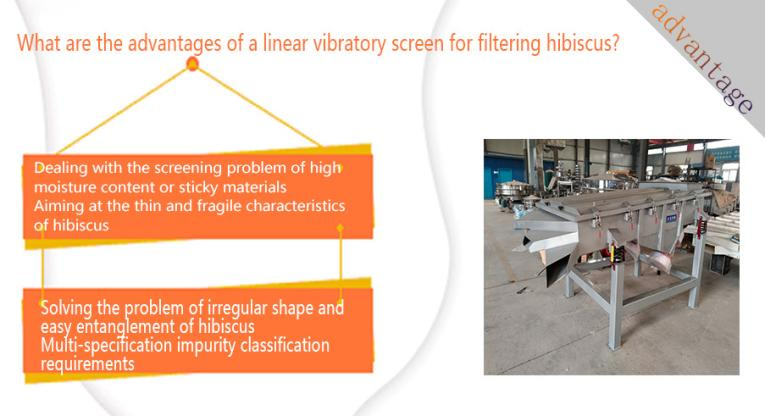

What are the advantages of a linear vibratory screen for filtering hibiscus?

Dealing with the screening problem of high moisture content or sticky materials: The moisture content of fresh hibiscus is as high as 70%-80%, and the petals are easy to stick to the screen, resulting in blockage of the screen holes and reduced screening efficiency. If the petals secrete mucus during processing (such as after damage), it is easier to stick to the screen. The upper coarse screen (such as 20-40 mesh) first removes large impurities such as branches, leaves, and pedicels to reduce the load of the lower fine screen.

Aiming at the thin and fragile characteristics of hibiscus: The vibration intensity of traditional vibratory screens is too high, which can easily cause the petals to tear and break, affecting the appearance of the scented tea or the extraction rate of essential oils. When the material accumulates on the screen surface, gravity extrusion may also cause damage to the petals. The linear vibratory screen uses dual motors to rotate synchronously in the opposite direction to produce a linear motion trajectory, so that the material is in a stable projectile state on the screen surface to avoid severe impact.

Solving the problem of irregular shape and easy entanglement of hibiscus: The appropriate throwing height and forward speed can reduce the mutual extrusion and entanglement between the petals, allowing them to pass through the screen more smoothly. The vibratory screen adopts a multi-layer screen design, which can gradually separate hibiscus and impurities of different sizes. The upper screen removes larger impurities, and the lower screen performs detailed classification to reduce the load of a single screen.

Multi-specification impurity classification requirements: large stems, broken leaves, sand and gravel and other impurities of different particle sizes need to be separated at the same time. The linear vibratory screen used to filter hibiscus adopts three layers of independent screening. The top layer is a 10mm square hole screen to remove large impurities; the middle layer is a 3mm round hole screen to separate complete petals; the bottom layer is a 0.8mm woven screen to recycle fine petals and pollen, which is suitable for different batches of raw materials.

Recommended mesh counts for filtering hibiscus

Linear vibratory screens for filtering hibiscus can be classified and sorted according to different screening purposes (such as impurity removal, grading, extracting whole flowers or petal fragments), and are suitable for screening conditions of dried hibiscus materials:

|

Screening purpose |

recommended mesh count range |

corresponding sieve hole size (mm) |

function description |

|

Preliminary impurity removal (removing large debris and stalks) |

5~10 mesh |

2.0~4.0mm |

intercepting large particles of impurities such as stalks and branches, retaining petal raw materials |

|

Separation of petals and leaves |

10~20 mesh |

0.85~2.0 mm |

separating larger leaves, broken petals and complete petals |

|

Petal grading (whole flowers and broken petals) |

20~30 mesh |

0.60~0.85 mm |

Realize the classification of complete petals and small petal fragments |

|

Extract pollen or extremely fine powder |

40~60 mesh |

0.25~0.43mm |

Separate extremely small particles or powders for pollen extraction or terminal processing |

|

Prevent screen penetration (bottom layer protection) |

80 mesh or above (optional) |

≤0.18mm |

As a bottom layer protection net to prevent dust from entering |

Application of linear vibratory screen for filtering hibiscus

Hibiscus processing production line: used for preliminary filtration after fresh flowers are picked, to remove impurities such as branches, leaves, mud and sand, and prepare for subsequent drying, extraction of essential oils, and making flower tea.

Food and pharmaceutical industry: Flower tea production can separate complete petals and powder to improve product quality; health care product processing can filter foreign matter in hibiscus raw materials to ensure the purity of the extract.

Research and laboratory scenarios: small-scale screening experiments to study the composition or process optimization of different parts of hibiscus.

Remove impurities from petals (such as broken leaves, twigs, and mud)

Grade petal particle size

Screening and pretreatment of dried/fresh

Prescreening before extracting pollen

Actual use effect

In actual production and use, some Chinese herbal medicine processing plants or food raw material companies use linear vibratory screens to process dried hibiscus, and have achieved the following results:

The petal screening integrity is maintained at more than 90%;

The impurity removal rate reaches more than 85%;

The screen service life is extended and the blockage rate is greatly reduced;

The daily output of a single device is stable at 200~500kg (depending on the dryness and humidity of the raw materials and the mesh size).

In short, with its high efficiency and precision, the linear vibratory screen for filtering hibiscus plays an irreplaceable role in various application fields of hibiscus, from flower tea production to medicinal ingredient extraction to seed screening, and effectively improves the efficiency and product quality of hibiscus processing.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Granules, powders, and paddle materials can be used.

-

Meet the needs of large-scale and high-precision screening

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification...

-

Tea seed grading linear vibrating screen

The tea seed grading linear vibrating screen is a key equipment used in the tea processing field for screening...

-

EAA polymer powder sieving machine

EAA polymer powder sieving machine is an automated equipment designed for high-precision sorting, ensuring that...

-

Sieving Machine For PET Recycling Plant

In the process of plastic recycling, the screening link is one of the key processes to ensure the purity and quality...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.