Cassava Starch Vibro Sifter

What is Cassava Starch Vibro Sifter?

Cassava Starch Vibro Sifter is used for fine screening of dried cassava starch. Using high-frequency vibrations generated by a vibrating motor, it efficiently breaks up the pressed cassava starch into uniform particles, effectively separating solids from liquids, removing impurities, and accurately grading the particles. This results in a cassava starch product with a uniform texture. The sieved cassava starch is then transported to packaging equipment or silos.

Cassava Starch Vibro Sifter uses vibration and a screen structure to separate impurities, coarse particles, and qualified cassava fines from cassava starch granules, thereby improving the purity and quality of cassava starch. Its mesh size typically ranges from 80 to 200 mesh, and the screen size can be adjusted to meet cassava starch production needs. A small-sized Cassava Starch Vibro Sifter has an hourly output of approximately 0.5-2 tons, while a medium-sized Cassava Starch Vibro Sifter can reach 2-5 tons.

What are the benefits of using a Cassava Starch Vibro Sifter to screen cassava starch?

Cassava starch easily absorbs moisture and forms clumps, has a fine particle size, and requires high purity. Conventional screening equipment is prone to clogging and uneven screening. The Cassava Starch Vibro Sifter specifically addresses these issues. Its high-frequency vibration principle quickly breaks up starch clumps, preventing them from accumulating and deteriorating. It also precisely separates impurities and starch particles of varying sizes, meeting the diverse demands for cassava starch purity and particle size uniformity. Structurally, it features a dedicated anti-sticking screen and sealing device. The anti-sticking screen reduces starch adhesion and clogging, ensuring screening efficiency, while the sealing structure prevents dust from forming, minimizing raw material waste and preventing dust pollution.

What types of vibrating screens are available for the Cassava Starch Vibro Sifter?

In cassava starch processing, the Cassava Starch Vibro Sifter is a core device for ensuring product fineness and purity. Three main types are available: Linear vibrating screens offer high throughput and a sturdy structure. They are suitable for initial impurity removal and coarse screening of cassava starch raw materials, efficiently processing large volumes of initial slurry. Circular vibrating screens utilize three-dimensional elliptical vibrations to achieve high screening accuracy and outstanding efficiency. They are ideal for mid-stage grading of cassava starch, effectively separating starches of varying fineness and ensuring uniformity in the finished product. Ultrasonic vibrating screens are specifically designed for screening highly viscous and fine cassava starch. The high-frequency vibrations of an attached ultrasonic system completely eliminate the problem of cassava starch easily clogging the mesh, making them ideal for producing ultrafine refined starch with a mesh size of 150 or higher.

Linear vibrating screen primarily serves as a coarse screen. When cassava starch becomes damp, the wet starch clumps need to be broken up and screened to remove fine fibers that were not fully separated during the initial crushing and extraction processes. The screening process ranges from 20 to 400 mesh.

Circular vibrating screen can be configured with two to four layers of screens to separate coarse powder, fine powder, and impurities simultaneously. It can screen cassava starch powders ranging from 20 to 500 mesh, with an output of 100 to 3,300 kg per hour. Most contact surfaces of the equipment are made of 304 steel to prevent impurities from contaminating the cassava starch.

Ultrasonic vibrating screen cassava starch is a lightweight, fine powder. The ultrasonic vibrating screen can screen cassava starch particles larger than 600 mesh. Due to the fine particle size, a brush can be installed on the ultrasonic screening machine to clear clogged screens and improve the screening efficiency.

Cassava Starch Vibro Sifter Parameters

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

What is the price of the screen selected for Cassava Starch Vibro Sifter?

When choosing a vibrating screen for cassava starch, the price varies depending on the material and application requirements. Nylon screens used in general food processing (such as pastries and vermicelli) cost approximately US$1–US$7 per square meter, offering a balance between fineness and screening efficiency. High-precision stainless steel woven wire mesh, used in high-end cosmetics or pharmaceutical excipients, costs US$3–US$30 per square meter, while stainless steel perforated plate costs US$10–US$60 per square meter. For industrial adhesive production, 60–80 mesh screens are typically chosen for their lower cost and faster screening speed. The price of a complete system also varies depending on the scale of the system. Small vibrating screens cost approximately US$400–US$1,500 per set, while systems with a capacity of 100–300 kg/h cost approximately US$1,000–US$2,500 per set.

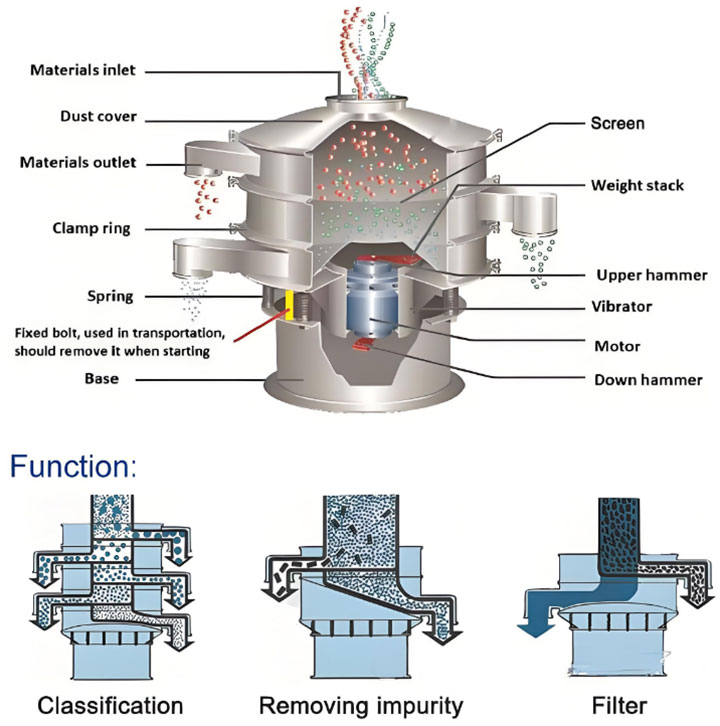

Main Components of the Cassava Starch Vibro Sifter

The core structure of the Cassava Starch Vibro Sifter consists of a vibrating motor, screen frame, screen, shock absorber, and frame. The vibrating motor is the core power source, driving the screen frame through eccentric vibration, which directly affects screening efficiency and accuracy. The screen frame, which secures the screen mesh, is typically made of stainless steel, which is corrosion-resistant, easy to clean, and prevents starch contamination. The screen mesh material and mesh size are selected as needed: nylon mesh is suitable for general food grade, while stainless steel mesh is suitable for high-end or pharmaceutical grade. The shock absorber, typically a spring structure, is installed between the screen frame and the machine frame to reduce vibration impact on the frame, reduce operating noise, and extend equipment life. The frame is the supporting structure and requires sufficient stability to ensure that the equipment does not deflect during high-frequency vibration.

Cassava Starch Vibro Sifter Applications

The Cassava Starch Vibro Sifter is widely used throughout the entire cassava starch processing chain and in related applications. During primary processing, it removes impurities such as crude fiber and sediment from starch, paving the way for subsequent purification. During refined starch production, it can be graded and screened to produce finished products of varying fineness, meeting the needs of the food, cosmetics, and pharmaceutical industries. During the production of starch derivatives (such as starch sugar and modified starch), it can pre-treat raw starch to ensure purity and avoid compromising the efficiency of subsequent chemical reactions. Furthermore, some smaller devices are suitable for laboratory use, providing screening services for cassava starch R&D experiments.

Cassava starch is a highly viscous starch extracted from the tuberous root of the tropical shrub cassava. In the food industry, it is used to make pearls in bubble tea, taro balls, mochi, crystal shrimp dumpling wrappers, meatballs, fruit pie fillings, cake fillings, and thickening soups and sauces. In the industrial sector, cassava starch is also used in a variety of applications, including papermaking, textiles, adhesives, and biodegradable materials.

Cassava Starch Vibro Sifter Solution

After sieving, the Cassava Starch Vibro Sifter can be used to transport qualified cassava starch to a packaging machine for quantitative packaging via a conveyor. Alternatively, it can be directly stored in a silo for later use. Furthermore, it can be equipped with a dust removal system to reduce dust pollution during the sieving process. For wet or dry processing lines, it can be integrated with a dehydrator, dryer, and pneumatic conveying system. Its compact, low-headroom design achieves high-capacity dry-wet separation within a limited space, creating a complete cassava starch screening and conveying solution.

The Cassava Starch Vibro Sifter is a core screening device in cassava starch production. Using a vibrating motor to drive the screen, it efficiently separates starch particles of varying particle sizes, significantly improving product purity and yield. Suitable for both primary processing and refining, this device meets the needs of diverse applications across the food, pharmaceutical, and industrial sectors. Featuring high screening accuracy, high throughput, energy efficiency, and a high degree of automation, it can be flexibly adapted to production lines of varying sizes, making it a key tool for optimizing starch quality and production processes.

-

Remove small stones, sand or clay particles, leaves, dust and other ...

-

Standard test sieve is a screening tool used for particle size analysis of materials.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Battery Anode Materials Vibrating Sieve

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

Related news-

Standard test sieve price

Standard test sieve price usually ranges from US$20 to US$300, depending on the size, material and accuracy level...

-

Vibro Sifter Flour

The Vibro Sifter Flour uses a motor-driven eccentric weight to generate three-dimensional vibration...

-

Vibro Sifter Baking Soda

Vibro Sifter Baking Soda is a process or equipment that uses a vibrating screen to sieve, grade, or filter baking soda...

-

Linear Vibrating Screen For Plastic Particles

Linear Vibrating Screen For Plastic Particles is used for screening and grading plastic particles...

-

High -frequency vibration sieve for latex paint filter

High -frequency vibration sieve for latex paint filter is a filtration device designed for high-viscosity liquid systems such as water-based paints ...

-

Vibro Sifter Magnesium Oxide

Vibro Sifter Magnesium Oxide refers to the process of using a vibro sifter to grade and screen magnesium oxide powder...

-

Electric Automatic Sieve Shaker Vibrating Sieve Machine

Electric Automatic Sieve Shaker Vibrating Sieve Machine are commonly used in laboratories and industrial production...

-

Tumbler Screening Machines

Tumbler Screening Machines are available in carbon steel, stainless steel, and special steel to meet...

-

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.

-

Reach Us

Xinxiang Dahan Vibration Machinery Co., Ltd.

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.

-

WhatsApp:+86 15236742901 E-mail:sale@xxdahan.com