Vibratory Sifter Screening Flour

What is Vibratory Sifter Screening Flour?

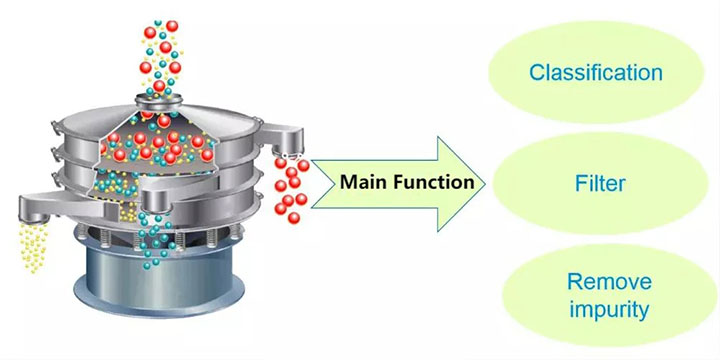

Vibratory Sifter Screening Flour uses motor-generated excitation to generate high-frequency vibrations on the sieve surface, causing the flour to be tossed, layered, and sifted across the sieve, effectively removing foreign matter such as stones and straw. The sieving range is 60-120 mesh, with a screening accuracy exceeding 95%, ensuring fine, uniform flour with consistent quality.

The equipment includes vibrating screens, ultrasonic screens, and oscillating screens. For clumping flour, the ultrasonic screen is optional. The ultrasonic system quickly breaks up clumps and keeps the screen clear. If the flour is damp or sticky, a nylon brush or bouncing ball can be added to the ultrasonic screen to effectively prevent clogging.

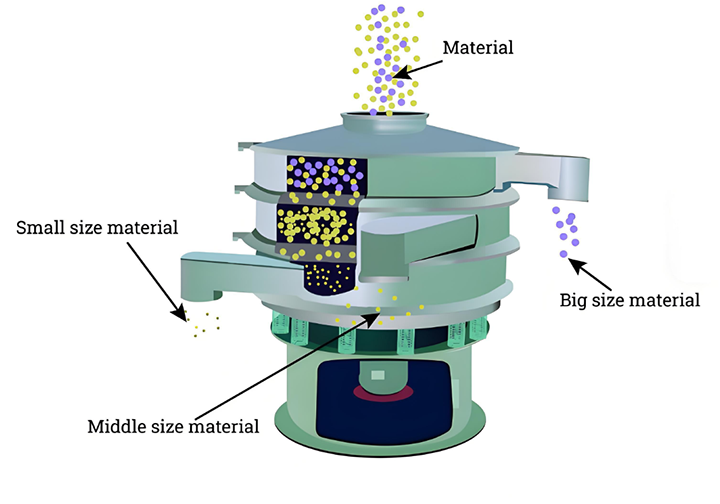

Working Principle of the Vibratory Sifter Screening Flour

The Vibratory Sifter Screening Flour uses excitation force to generate high-frequency vibrations on the sieve surface, causing the flour to be tossed, tumbled, and layered on the sieve, thereby separating the flour from impurities. Typically, the sieve has an inclination angle of 15° to 20°, an amplitude of 1 to 3 mm, and a vibration frequency of 900 to 1500 vibrations per minute. An angle that is too large can cause the material to slide off quickly, resulting in inadequate screening; an amplitude that is too small can prevent the material from being fully agitated, leading to clogging of the sieve mesh; and insufficient excitation force can reduce screening efficiency. In practice, the excitation force, amplitude, and frequency can be optimized by adjusting the vibration motor weight angle (generally between 0° and 180°) and the sieve tension. This improves flour screening accuracy and yield while minimizing clogging and dust generation.

Vibratory Sifter Screening Flour Type Selection

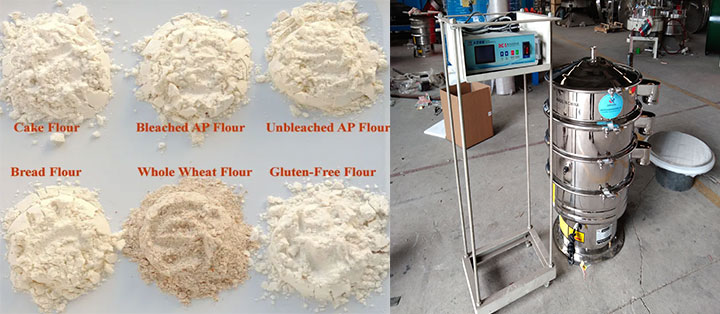

When selecting a Vibratory Sifter Screening Flour, for medium-fine flour screening, choose a rotary vibrating screen; for high-fine flour screening, choose an ultrasonic screen. If screening is gentle and requires protection of the material, choose a swing screen.

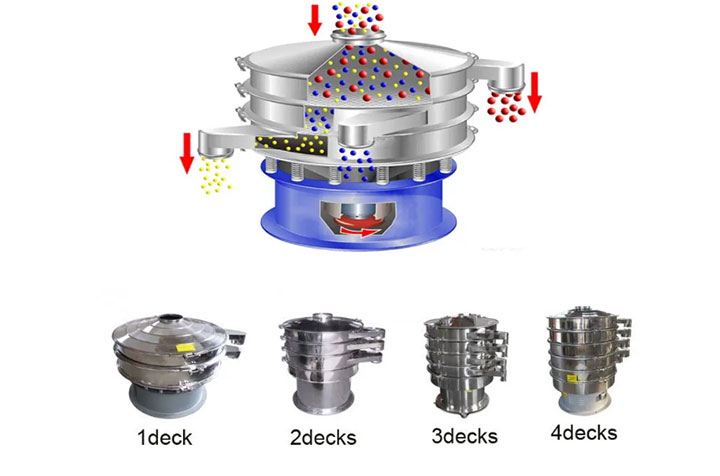

Circular vibrating sieves: Typically equipped with 1-5 screen layers, they can achieve multiple particle size classifications. The screens are typically fixed with a press frame or bolt-on mounting system, and feature a damping spring at the bottom to minimize vibration impact on the equipment foundation. These sieves are suitable for general flour grading, such as coarse and fine screening of common wheat flour and whole wheat flour, and for impurity removal (removing bran fragments and foreign matter from the flour). They are particularly well-suited for small to medium-sized production capacities, such as 1-15 tons/hour.

Ultrasonic vibrating screens retain the main frame of a circular vibrating screen, but with ultrasonic vibrators installed below the screens, one for each screen layer. The frequency is adjustable via an ultrasonic controller, typically between 20-40kHz. The screens typically use fine, high-precision mesh sizes of 100-400 mesh. This screen is designed for highly refined, easily agglomerated flours, such as cake flour, cake flour, and starch-based flours. Ultrasonic Vibratory Sifter Screening Flour addresses the issues of fine powder clogging and low screening efficiency, making it suitable for the food and baking industries, which require high particle size precision.

Swing screen is suitable for screening high-precision, high-value-added, or dust-prone flours, such as starch and rice flour. Its gentle, artificial-sounding oscillation effectively prevents flour particle breakage and screen clogging. Its mesh size generally ranges from 40 to 325, and the screen body typically features 2 to 6 layers, enabling simultaneous screening of 2 to 7 particle size grades. Screening output ranges from 200 kg to 5 tons per hour. The machine operates smoothly, with noise levels below 75 dB, and is easy to maintain, making it suitable for continuous, long-term operation.

Number of Screening Layers for a Vibratory Sifter Screening Flour

In the flour sieving process, the more screen layers a vibratory sifter screening flour has, the finer the impurity removal and grading objectives can be achieved simultaneously. The number of screening layers generally functions as follows:

1-2 layers of screens perform "coarse screening," removing large impurities such as bran, stones, and fiber from the flour without fine grading. 3-4 layers of screens perform "impurity removal + preliminary grading," separating the flour into 2-3 grades based on particle size, such as coarse flour, standard flour, and fine flour. 5 or more layers of screens perform "fine grading + deep purification," achieving multi-dimensional particle screening for high-demand flours such as cake flour and cake flour, while also removing trace impurities such as bran particles and dust.

What are the advantages of using a Vibratory Sifter Screening Flour?

The Vibratory Sifter Screening Flour optimizes the flour processing process from multiple perspectives, including purity, quality, and processing efficiency. The specific benefits can be categorized into the following five categories:

Improving Purity: High-frequency vibration and a specialized screen remove impurities such as dust and sand, preventing them from affecting taste or damaging equipment. Vibratory Sifter Screening Flour also breaks up flour clumps, ensuring a uniform texture and preventing interference with subsequent processing.

Optimizing Quality: 40-100 mesh screens can be selected as needed to screen flour with consistent particle size, eliminating quality fluctuations. Uniform flour also blends better with other ingredients, resulting in finer, chewier baked goods.

Improving Efficiency: It can be integrated with production lines for continuous operation, processing hundreds of kilograms to several tons of flour per hour, far exceeding manual labor. It also reduces labor costs, and a screening recovery rate of over 98% minimizes flour loss.

Ensuring Safety: Food-grade vibrating screens are mostly made of 304/316 stainless steel, making them easy to clean and meeting hygiene standards. Some Vibratory Sifter Screening Flour sealed structures to prevent dust and cross-contamination, improving the workshop environment.

Auxiliary Processing: Pre-screening hard impurities reduces subsequent equipment wear and maintenance costs. Uniform flour also ensures consistent taste and appearance in the finished product, enhancing brand reputation.

Vibratory Sifter Screening Flour Solutions

Vibratory sifter screening flour allows for flexible equipment configuration based on the site environment. For indoor operations with high dust concentrations, explosion-proof vibrating screens equipped with explosion-proof motors and sealed, dust-proof structures can be selected to ensure safety and cleanliness. For outdoor installations, 304 or 316 stainless steel models should be used for their rust and corrosion resistance. For large-scale flour production lines with daily output exceeding 5 tons, multiple vibrating screens can be connected in parallel for continuous screening.

The Vibratory Sifter Screening Flour is suitable for screening a variety of flours, including all-purpose wheat flour, bread flour, cake flour, bread flour, whole wheat flour, and multi-grain flour. Flour screening is not only a fundamental step in removing impurities, but also a critical step in ensuring food safety, optimizing flour quality, and improving production efficiency. This equipment is suitable for food processing, flour mills, bakeries, catering companies, and R&D laboratories.

-

Powder sieving machine is designed for high volume sieving of powders to remove oversized contaminants ...

-

metal powder sieving machine sends ultrasonic waves to the surface of the sieve to prevent clogging or damage of the sieve...

-

Vibro Sifter Flour

The Vibro Sifter Flour uses a motor-driven eccentric weight to generate three-dimensional vibration...

-

Vibro Sifter Baking Soda

Vibro Sifter Baking Soda is a process or equipment that uses a vibrating screen to sieve, grade, or filter baking soda...

-

Linear Vibrating Screen For Plastic Particles

Linear Vibrating Screen For Plastic Particles is used for screening and grading plastic particles...

-

High -frequency vibration sieve for latex paint filter

High -frequency vibration sieve for latex paint filter is a filtration device designed for high-viscosity liquid systems such as water-based paints ...

-

Vibro Sifter Magnesium Oxide

Vibro Sifter Magnesium Oxide refers to the process of using a vibro sifter to grade and screen magnesium oxide powder...

-

Tumbler Screening Machines

Tumbler Screening Machines are available in carbon steel, stainless steel, and special steel to meet...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.