Screening Machine

![[field:title/]](/uploads/250506/6-2505061S33XU.png)

Callback

Screening Machine

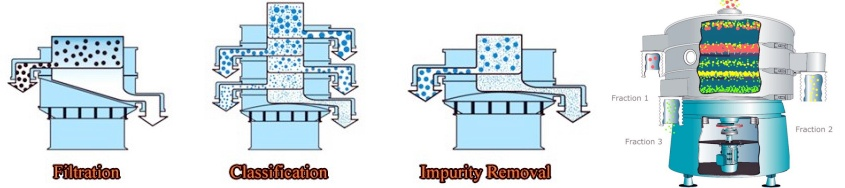

Screening machine is a mechanical equipment that uses physical separation technology to classify, remove impurities or accurately sort granular, powdery or block materials. Its core function is to separate materials into products of different specifications or purity according to their particle size, shape, density and other characteristics.

| Mesh size: | 2-500 mesh |

| Capacity: | 100-3300kg/h |

| Number of layers: | 1-5 layers |

| motor power: | 0.75-5.5kW |

| Materials: | Plastic, carbon steel, stainless steel |

| Customization: | Extended discharge port, raised base cylinder, etc. |

| Applicable materials: | Powders, granules, viscous substances, liquids |

What is a screening machine?

Screening machine is a device that realizes material classification and impurity removal through a screen, which can meet the needs of diversified material classification. Using advanced vibration technology, it can efficiently and accurately separate various powders, particles and slurry materials. The equipment can be configured with sieves of different mesh sizes according to your specific needs, from coarse screening (such as 4-20 mesh) to remove large particle impurities, to medium screening (such as 20-100 mesh) for particle size classification, and then to fine screening (such as 100-500 mesh or even higher) to obtain ultra-fine powder. By adjusting the vibration frequency (such as 800-3000 rpm) and amplitude, the processing capacity ranges from hundreds of kilograms to tens of tons per hour, and is widely used in chemical, food, medicine, mineral processing and other industries.

Types of screening machines

Screening machines are indispensable pretreatment equipment in the production of Chinese medicinal materials and granular preparations. They are mainly used to remove impurities (such as sand, fiber, powder) in raw materials and grade them according to particle size to ensure the quality of finished products. The following are common types:

|

Type |

Swing screen |

Linear vibrating screen |

Rotary screen |

|

Picture |

|

|

|

|

Principle |

Three-dimensional artificial swing motion, low frequency and high amplitude |

High frequency vibration motor drive, vertical motion trajectory |

Horizontal rotary centrifugal screening |

|

Advantages |

Screening accuracy ≥95%, mesh range 20-200 mesh, processing capacity 300-1000kg/h, suitable for sticky/light materials |

Large processing capacity (up to 5t/h), high screening efficiency, but high noise (≥80dB) |

Fully enclosed design, anti-cross contamination, but the screen replacement is more complicated |

|

Application |

Medium Medicinal slices, granules, ultrafine powders |

Classification of bulk Chinese medicinal materials after coarse crushing |

Refining of toxic medicinal materials and precious fine medicinal materials |

|

Type |

Screening accuracy |

Applicable mesh |

Noise |

Energy consumption |

Maintenance cycle |

|

Swing screen |

≥95% |

20-200 |

≤75dB |

1.5kW |

3 months |

|

Vibrating screen |

85-90% |

10-100 |

≥80dB |

3kW |

1 month |

|

Rotary screen |

90-95% |

30-150 |

≤65dB |

2.2kW |

6 months |

Features of screening machines

Screening machines can classify materials according to particle size, shape, and density; they are suitable for dry and wet, light and heavy, fragile or easily sticky materials, reducing breakage and clogging; they maintain the integrity of materials and reduce losses; they have strong continuous processing capabilities, and adjustable vibration and screen angle improve screening efficiency.

Efficient screening: The screening machine can quickly and effectively screen materials according to preset standards, has a high processing capacity, can process a large amount of materials in a short time, and improve production efficiency.

Accurate classification: It can accurately classify materials according to their particle size, shape, density and other characteristics, separate materials of different specifications, and meet the requirements of material particle size in different production links.

Multiple screening methods: There are various screening principles and methods, such as vibration screening, rotary screening, airflow screening, etc., and the appropriate screening method can be selected according to the nature of the material and the screening requirements to achieve the best screening effect.

Simple structure: It usually has a relatively simple structure, which is easy to install, operate and maintain. The screening machine has relatively few parts, which reduces the possibility of failure, reduces maintenance costs and downtime.

Strong adaptability: It can adapt to the screening of materials of different types and properties. Whether it is granular, powdery or flaky materials, effective screening can be achieved by adjusting the parameters and structure of the screening machine.

Video of screening machine

Technical parameters of screening machine

|

Technical parameters |

Unit |

Typical value range (for reference only) |

Remarks |

|

Processing capacity (output) |

t/h or m³/h |

1-500+ |

Varies according to material density and equipment model |

|

Number of screening layers |

Layers |

1-5+ |

Determines the number of particle sizes that can be separated at the same time |

|

Screen surface size |

square meters |

0.5-50+ |

Effective screening area of a single layer of screen |

|

Screen hole size (aperture) |

mm or μm |

0.02-100+ |

Choose according to the particle size range of the material to be separated |

|

Screening efficiency |

% |

80-99+ |

Refers to the proportion of materials that meet the particle size requirements and are effectively separated, which is affected by many factors |

|

Vibration frequency |

Hz |

10-50+ |

Affects the movement speed and separation effect of materials on the screen surface, and different types of screen machines vary greatly |

|

Amplitude |

mm |

1-10+ |

Affects the throwing height and looseness of materials, and different types of screen machines vary greatly |

|

Applicable materials |

|

Various |

For example: sand, mineral powder, chemical raw materials, grain, food, etc., specific models are targeted |

What is the working principle of the screening machine?

Screening machines usually use vibration, rotation, shaking and other methods to make the material move on the screen surface, and divide the material into different particle size levels or types according to the size of the screen hole. Materials larger than the screen hole size are left on the screen surface, while materials smaller than the screen hole size fall through the screen hole, thereby realizing the screening and separation of materials.

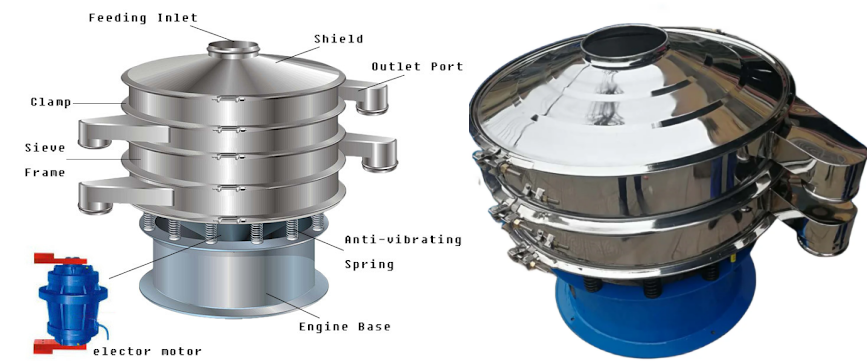

The structure and composition of the screening machine

Frame: The frame used to support the entire screening machine structure, which needs to have sufficient strength and stability.

Drive device: Provides the power required for the movement of the screening machine. Common ones include motor-driven eccentric blocks to generate vibration, hydraulic drive, pneumatic drive, etc.

Screen box: The component that accommodates and supports the screen, usually designed as a multi-layer structure to achieve multi-level grading.

Feeding and discharging device: The material is evenly transported to the screen surface, and materials of different sizes are discharged separately.

Support and shock absorber: Used to support the screen box and reduce the impact of vibration on the surrounding environment. Common ones include springs, rubber shock absorbers, etc.

Recommended mesh number of screening machine

|

Mesh number |

Application field |

Applicable particle size range |

|

20 mesh |

Coarse particle screening |

0.85mm - 1.0mm |

|

40 mesh |

Building materials, chemicals |

0.42mm - 0.5mm |

|

60 mesh |

Food, medicine |

0.25mm - 0.3mm |

|

80 mesh |

Cosmetics, coatings |

0.18mm - 0.2mm |

|

100 mesh |

Fine chemicals, plastics |

0.15mm - 0.18mm |

|

200 mesh |

Ultrafine screening |

0.075mm - 0.1mm |

|

300 mesh |

Nano materials, special powders |

0.05mm - 0.075mm |

Applicable materials for screening machines

The screening machine is suitable for various materials that require particle size separation, impurity removal, classification, dehydration and other operations. Its scope of application is very wide, covering the following main categories:

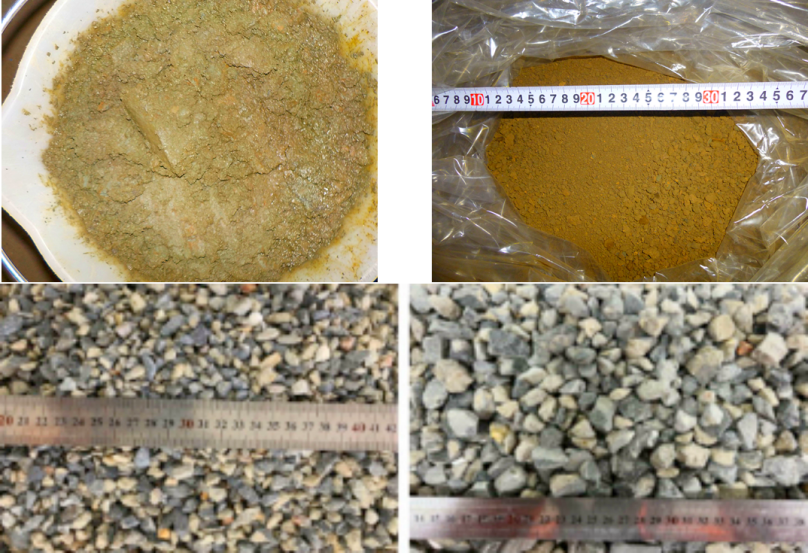

Powdered materials: resin powder, coating powder, flour, starch, cement, lime powder, PVC powder, PE powder, fine powder of various ores, etc.

Granular materials: plastic particles, rubber particles, rice, beans, catalyst particles, gravel, crushed stone, various animal feed particles, etc.

Slurry and liquid materials: separation of solid particles in paints and coatings; removal of fibers or solid impurities in fruit juices and vegetable juices; solid-liquid separation after various chemical reactions.

Application of screening machine

Sieving machines play an important role in all walks of life, separating mixed materials into different components by differences in size, shape or other physical properties. Here are some specific application scenarios:

① Mining and mineral processing: After the ore is crushed, vibrating screens with different apertures are used to grade the ore, and ores of different particle sizes are used for subsequent beneficiation, smelting and other processes. For example, the crushed iron ore is divided into coarse, medium and fine materials. The tailings after beneficiation are screened to separate minerals or materials that are still valuable. In the quarry, multi-layer vibrating screens are used to grade the crushed stones to produce building aggregates such as sand and gravel of different specifications.

② Agriculture: Equipment such as vibrating screens are used to remove impurities such as weeds, straw, and sand from grains, and grade them according to grain size. The screening machine also grades the seeds by size, removes broken or incomplete seeds, ensures the quality of sowing, and improves the germination rate and the robustness of the seedlings. In the feed production process, screening equipment is used to remove impurities in the raw materials and grade the finished feed by particle size to meet the nutritional needs of animals at different growth stages.

③ Recycling industry: Use screening machines to separate different components such as concrete blocks and bricks in construction waste. In waste treatment plants, use screening equipment to initially separate organic matter, inorganic matter, recyclables, etc. in domestic waste, which facilitates subsequent composting, incineration or resource recovery. The crushed waste plastics are graded through sieves with different apertures to separate plastic particles of different sizes for the production of recycled plastics.

④ Food and beverage industry: In the production process of flour, milk powder, powdered sugar, etc., high-precision screening machines are used to remove lumps and impurities to ensure the fineness and quality of the products. Food raw materials such as rice, beans, and nuts are graded by size to ensure the uniformity of product specifications. Use screening equipment to remove impurities in spices and perform particle size control to ensure the flavor and quality of condiments.

Pharmaceutical industry: Particle size control of drug raw materials and intermediates to ensure the solubility and bioavailability of drugs. For example, aspirin powder is screened to obtain a particle size range that meets the requirements. In the production process of tablets and granules, screening equipment is used to control the uniformity of particle size and ensure the quality and appearance of the product.

Screening Machine Price

Small, manual or simple screening machines, suitable for laboratory or small-batch production, typically cost between $1,000 and $3,000. Standard industrial-grade vibrating screens or drum screens offer basic automation and moderate processing capacity, priced roughly between $3,000 and $8,000. Large, fully automated, high-precision, or customized screening systems, such as large linear vibrating screens, probability screens, or air classifiers for mining or fine chemicals, can start at $10,000. Note that stainless steel is more expensive than carbon steel; your specific process requirements should be clearly defined before requesting a quote.

Screening machine manufacturers

DaHan Vibration Machinery manufactures both standard and custom-designed screening machines, such as extended discharge ports, wheels for easy movement, and horn-shaped feed inlets. With years of experience, the manufacturer is committed to providing users with convenient, one-stop screening machinery selection and maintenance services.

Screening machines are very important separation equipment in industrial production, involving almost all industries that require solid particle separation or solid impurity removal in liquids. Different types and specifications of screening machines can be selected according to different material characteristics and process requirements.

-

Sand screening machine for sandScreening and grading, due to the different particle size of sand, com ...

-

Millet vibrating sieve is widely used in millet processing industry, including millet processing plants, rice flour plants, rice......

-

Powder Coating Ultrasonic Sieving Machine

The screening accuracy can be increased by 1-70%, and the output can be increased......

-

Tumbler Screening Machines

Tumbler Screening Machines effectively avoid material accumulation and blockage, and have strong stab ...

-

White sugar powder screening machine

White sugar powder screening machine has a sieving mesh size of 30-150 mesh. It can screen different ...

-

Dry Material Silica Powder Screening Machine

The dry material silica powder screening machine is an efficient vibrating screening equipment, speci ...

-

Tumbler Screening Machine for Glass Frits and Glass Graules

Tumbler screening machine for glass frits and glass granules is a drum screening equipment used to sc ...

-

How to Apply Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine is a fine powder sieving machine with relatively perfect te ...

-

Sunflower seeds screening machine

Sunflower seed screening machine, also known as sunflower seed vibrating screen or separator, is a special equipment ...

-

Powder Sieve Machine Price

Powder Sieve Machine Price varies depending on the specifications, and the market quotation is usually between US$500 and US$8000...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.