Copper Shavings Core Sand Screening Machine

Copper Shavings Core Sand Screening Machine is a device for screening copper core sand generated during casting or machining processes. It separates and recovers copper shavings mixed in with the core sand, while simultaneously regenerating the sand. The processing capacity of a single unit ranges from 1 to 20 tons per hour. The copper shavings being processed are mostly in the form of flakes, spirals, or short fibers, typically 1–20 mm in length, while the core sand is mostly granular, with a particle size range of 0.1–5 mm. This equipment can screen particle sizes from 0.1 to 10 mm, recovering valuable copper shavings while ensuring the cleanliness and reusability of the core sand.

What is the screening process of the Copper Shavings Core Sand Screening Machine?

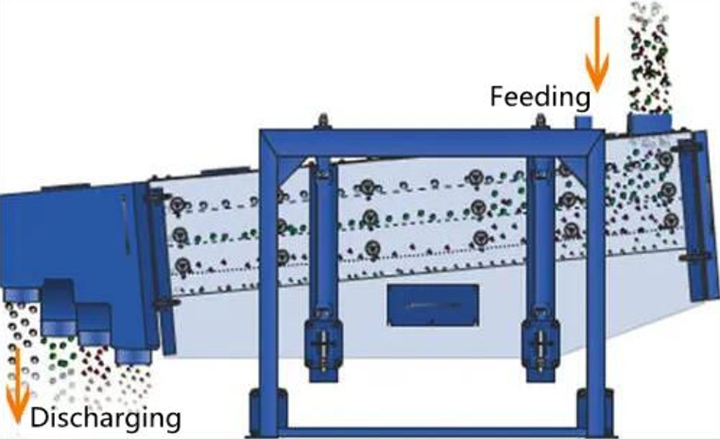

The Copper Shavings Core Sand Screening Machine takes into account the characteristics of material density differences, complex morphology, and high powder content when screening copper core sand. After feeding, the mixture is loosened by vibration or swaying. Granular core sand passes through the screen under the combined forces of gravity and vibration, while larger, irregularly shaped copper shavings are trapped on the screen surface and discharged along a predetermined trajectory. For core sand containing oil, moisture, or prone to agglomeration, the equipment can adjust the amplitude, frequency, and screen structure to keep the material dispersed and prevent screen clogging.

Function of the Copper Shavings Core Sand Screening Machine

The Copper Shavings Core Sand Screening Machine reduces the sand content in copper shavings and the copper content in the sand, laying the foundation for recycling. Dust generated during screening can be collected centrally through a closed structure connected to a dust collection system, helping to improve the working environment. If the mixture contains iron impurities, the amount of copper shavings after screening is reduced, and the subsequent magnetic separator only needs to process "copper shavings + a small amount of iron shavings," reducing the load. Copper shavings with most of the sand removed are purer and smaller in size, facilitating packaging, storage, and transportation, thus improving the commercial quality and market value as scrap copper. It can screen out large-sized impurities such as copper shavings, wood chips, and flash, preventing them from entering old sand recycling systems such as crushers, and avoiding equipment blockage or damage. Vibrating screens can be connected to conveyors, crushers, and other equipment to form automated processing lines, achieving continuous material feeding, screening, and discharge.

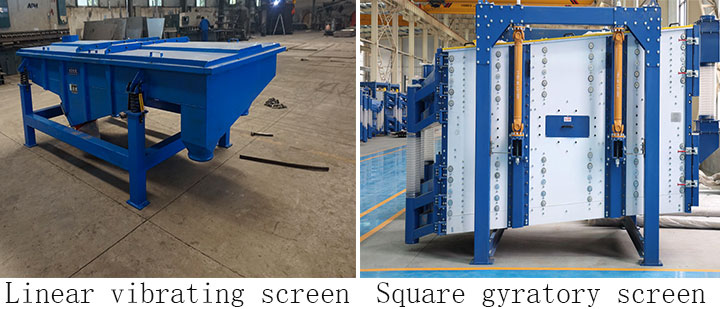

Comparison of Two Types of Copper Shavings Core Sand Screening Machines

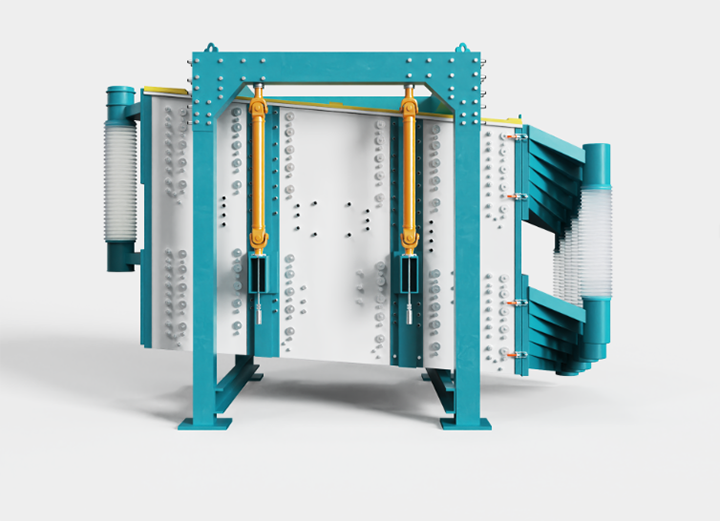

In Copper Shavings Core Sand Screening Machines, linear vibrating screens and square gyratory screens are two common types of screening equipment. Linear vibrating screens are driven by dual vibrating motors, with material moving in a straight line. They have a large screening capacity per unit time and are suitable for copper shavings core sand with high throughput requirements and relatively concentrated particle size distribution. Single-layer or multi-layer structures can achieve coarse and fine screening in parallel. Square gyratory screens simulate manual screening trajectories, operating smoothly and with a long material residence time. They have a better grading effect on easily entangled or irregularly shaped copper shavings, resulting in higher screening accuracy. Both types of screens can be used in conjunction with crushers, elevators, dust removal systems, magnetic separators, and automatic packaging equipment to form continuous, closed screening production lines.

Copper Shavings Core Sand Screening Machine on-site demonstration

Copper Shavings Core Sand Screening Machine Case Study

A copper valve foundry uses a linear vibrating screen to process copper shavings and sand mixtures generated during the grinding and cleaning process, with a daily processing capacity exceeding 20 tons. After screening, the sand content of the copper shavings is reduced to below 3%, allowing for direct remelting. The sand is recycled after processing by a recycling system, saving over one million yuan annually in new sand costs. A "vibrating screen + high-power magnetic separation" linkage system is installed at the recycling resource processing center to purchase mixtures from various foundries for separation and purification. The resulting pure copper shavings are sold as secondary metallurgical raw materials, and the recycled sand is sold as roadbed material, achieving 100% resource utilization of solid waste, resulting in significant economic and environmental benefits.

Copper shavings and core sand are a mixture of industrial solid waste generated in the foundry industry. The Copper Shavings Core Sand Screening Machine separates and recycles these materials, allowing them to be reused in production, thus reducing material consumption. The price of a Copper Shavings Core Sand Screening Machine typically ranges from $5,000 to $30,000, depending on throughput, screening structure, material configuration, and level of automation. You can contact Dahan Machinery for better equipment model options.

-

Double deck with incline vibrating screen

Double deck with incline vibrating screen adopts high-quality wear-resistant screen mesh and high-strength steel structure.

-

Liquid vibratory sifter is a device used to separate solid particles from liquid.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Raw sesame is often mixed with soil, sand, metal chips, glass fragments, etc. These impurities not only affect the taste.

-

Double Deck Vibrating Screen For Fertilizer

Double Deck Vibrating Screen For Fertilizer is used for grading and removing impurities from granular materials such as compound fertilizers, urea, phosphate fertilizers, and organic fertilizers...

-

Limestone double deck with incline vibrating screen

Limestone double deck with incline vibrating screen utilizes reciprocating vibration provided by an exciter motor or eccentric shaft to cause the material to move...

-

Double Deck Vibrating Screen For Silica Sand

Double Deck Vibrating Screen For Silica Sand is a vibrating screening machine with upper and lower screens for screening silica sand...

-

Double Deck Vibrating Screen For Recycling

Double Deck Vibrating Screen For Recycling uses a vertically stacked design with two layers of screens to simultaneously separate recyclable materials such as plastics...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.