Screening Equipment DH-1000-2S

Screening equipment DH-1000-2S is a circular vibrating screening equipment with a diameter of 1000mm and two discharge ports. It is suitable for grading and removing impurities of dry powder, granular or liquid materials with a particle size of 0.028mm-25mm (about 500 mesh to 36 microns) and a screening mesh of 20-200. The equipment adopts a double-layer screen design, with an equipment power of 0.75kW, high screening efficiency, and an accuracy of more than 95%. The range is usually 20 mesh to 500 mesh, which meets the screening requirements of different materials. The fully enclosed design, the discharge port can be adjusted 360°, and the output can reach 1-2 tons/hour, which can efficiently complete the screening task of large quantities of materials.

Video of screening equipment DH-1000-2S

What is the working principle of screening equipment DH-1000-2S?

Screening equipment DH-1000-2S is a high-efficiency circular screening equipment produced by Xinxiang Dahan Vibration Machinery. It has a wide range of screening meshes, up to 10-500 meshes, and is widely used in the screening and grading of materials such as particles, powders, and liquids.

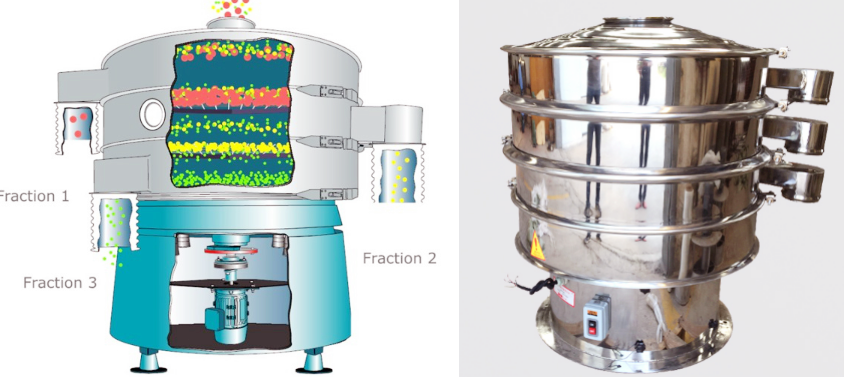

① Vibration generation: The motor converts the rotational motion into horizontal, vertical, and inclined three-dimensional motion through the eccentric weight, and transmits it to the surface of the size net. The amplitude and motion trajectory can be adjusted by adjusting the phase angle of the eccentric block to adapt to different gains.

② Material movement: The material enters the screen surface from the top feed port and moves in a spiral increment under the action of three-dimensional vibration. Fine particles fall into the lower layer or collection box through the screen holes, and the larger particles move along the screen surface to the discharge port.

③ Grading: Two layers of screens realize three-level grading (screened material, first layer of screened material, second layer of screened material). The screen aperture decreases, and different particle sizes are screened step by step.

Applicable materials of screening equipment DH-1000-2S

The structure of screening equipment DH-1000-2S enables it to separate three materials of different particle sizes at the same time. Due to its strong versatility and moderate processing capacity, it is widely used in the following types of materials:

Powdered materials: various fine powders, such as flour, starch, milk powder, metal powder, chemical powder, pharmaceutical powder, etc.

Granular materials: various particles, such as sugar, salt, monosodium glutamate, resin particles, catalysts, abrasives, etc.

Small block materials: small block materials, such as pebbles, gravel, feed particles, etc.

Dry and wet materials: As long as the humidity and viscosity of the material are within the allowable range, the equipment can usually handle it. But for high humidity or sticky materials, special screen designs or auxiliary devices may be required.

What are the advantages of DH-1000-2S screening equipment

Handling materials blocking the screen: fine powder, wet or sticky materials are easy to adhere to the screen, blocking the mesh, reducing screening efficiency and even causing downtime. Strong vibration helps the material jump and loosen on the screen surface, reducing the chance of adhesion. By adjusting the eccentric block of the vibration motor, the amplitude and vibration frequency can be changed to reduce clogging.

Solving the problem of low screening efficiency and processing capacity: DH-1000-2S has two layers of screens, which can perform coarse and fine screening at the same time to improve separation efficiency. Choose the appropriate upper and lower screen apertures according to needs to achieve efficient grading. Reasonable feeding method can ensure that the material is evenly distributed on the screen surface to avoid local overload.

Adapting to the problem of complex material characteristics: high slurry, wet silo or slurry silo is easy to adhere or poor fluidity during screening, making it difficult to effectively separate. screening equipment DH-1000-2S supports 0-500 mesh screening of dry and wet materials and 0-600 mesh slurry filtration, suitable for high viscosity materials such as slurry or wet powder.

Multi-specification grading requirements: The equipment is equipped and three layers of discharge ports, which can realize orders of different specifications and particle sizes at the same time to meet the needs of multi-specification grading. For example, for titanium dioxide (40 mesh, 60 mesh), the output can reach 400 kg/hour. It can be customized according to needs (2-500 mesh), supporting a variety of grading applications from coarse particles to ultrafine powders.

Recommended mesh size of screening equipment DH-1000-2S

Recommended mesh size of screening equipment DH-1000-2S in different industries and materials, suitable for dry powder, granular or liquid materials with particle size of 0.028mm-25mm (about 500 mesh to 36 microns). The mesh size selection is based on material characteristics, screening purpose (grading, impurity removal, filtration) and production requirements (1-2 tons/hour).

|

Industry |

Material |

Recommended mesh |

Particle size range |

|

Chemicals |

Urea, compound fertilizer |

20-50 mesh |

0.3-5mm |

|

Calcium carbonate, talcum powder |

100-200 mesh |

0.074-0.15mm |

|

|

Titanium dioxide, carbon black |

200-300 mesh |

0.045-0.074mm |

|

|

Food |

Flour, corn flour |

80-150 mesh |

0.1-0.18mm |

|

Powdered sugar, monosodium glutamate |

50-120 mesh |

0.125-0.3mm |

|

|

Juice, soy milk |

100-200 mesh |

0.074-0.15mm |

|

|

Medicine

|

Chinese medicine powder, vitamin powder |

100-400 mesh |

0.038-0.15mm |

|

pill filler |

50-100 mesh |

0.15-0.3mm |

|

|

Metallurgy |

Mining aluminum powder, copper powder |

100-500 mesh |

0.028-0.15mm |

|

quartz sand, limestone powder |

20-100 mesh |

0.15-5mm |

|

|

Building materials |

clinker, gypsum |

50-150 mesh |

0.1-0.3mm |

|

machine-made sand |

20-50 mesh |

0.3-5mm |

Mesh selection basis:

Coarse screen (20-50 mesh): suitable for large-particle materials (such as fertilizers, sand and gravel), used for impurity removal or preliminary classification.

Medium screen (50-150 mesh): suitable for medium-sized materials (such as flour, gypsum), taking into account both output and precision.

Fine sieve (150-500 mesh): used for fine powder or high-precision requirements (such as pharmaceutical powder, metal powder), anti-blocking device is required.

Application of screening equipment DH-1000-2S

The screening equipment DH-1000-2S has the characteristics of high-efficiency screening (1-2 tons/hour), floor grading (two-layer screen) and adaptability to a variety of materials (particle size 0.028mm-25mm, 20-500 mesh), and is widely involved in chemical, food, medicine, metallurgy, building materials and other industries.

Powder metallurgy: various metal powders such as iron powder and copper powder are screened according to certain particle size requirements. DH-1000-2S can accurately screen out metal powders of different mesh sizes for the manufacture of high-precision mechanical parts, automotive parts, etc., to ensure uniform density and performance of the product.

Pigment production: The pigment particles are screened into different finenesses to meet the needs of different application fields. For example, pigments used in coatings and inks require finer particle sizes to ensure their dispersion and glossiness. Screening equipment DH-1000-2S can accurately control the particle size distribution of pigments and improve the quality and stability of pigments.

Magnetic material production: In the production process of magnetic materials such as ferrite, NdFeB, etc., magnetic powders need to be screened to control their particle size distribution, thereby affecting the magnetic properties and application effects of magnetic materials. Screening equipment DH-1000-2S can meet the strict requirements for powder particle size in magnetic material production and improve the quality and performance of magnetic materials.

Pharmaceutical production: Many raw materials and excipients need to be screened to ensure accurate dosage and uniform mixing of drugs. For example, drug powders in tablets, capsules and other drugs need to be screened to control particle size to ensure the quality and efficacy of drugs. DH-1000-2S can accurately screen drug powders under conditions that meet the requirements.

The screening equipment DH-1000-2S uses high-frequency vibration driven by dual motors and multi-layer screens to achieve fast and accurate material grading. Its modular design and flexible and adjustable parameters make it a universal and efficient equipment for processing granular materials in the industrial field. In practical applications, it is necessary to optimize operating parameters in combination with material properties (particle size, humidity, viscosity) to maximize efficiency.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Granules, powders, and paddle materials can be used.

-

Meet the needs of large-scale and high-precision screening

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical and chemical properties of...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification, impurity removal or particle...

-

Tea seed grading linear vibrating screen

The tea seed grading linear vibrating screen is a key equipment used in the tea processing field for screening and grading tea seeds. Its core function is to achieve...

-

EAA polymer powder sieving machine

EAA polymer powder sieving machine is an automated equipment designed for high-precision sorting, ensuring that the EAA polymer powder has uniform particle size....

-

Glutinous rice ball coating machine

Glutinous rice ball coating machine is designed for all kinds of quick-frozen glutinous rice ball, aiming to achieve efficient and uniform powder adhesion. The equipment....

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.