Paint for filter sieve

What is Paint for filter sieve?

Paint for filter sieve is a device that separates large particle impurities, lumps, inadequately dispersed pigments and fillers, crusts, and debris from paint. It is mainly used to filter impurities in paint, uniform particles, improve product quality, and ensure the fineness, uniformity and construction performance of paint. It plays a very important role in the production, processing, transportation and use of paint.

Paint for filter sieves. Common types of screening equipment include filter sieves, high-frequency sieves, and vibrating screens. Specialized coatings can be applied to optimize screen performance for different filter applications, such as filter sieves for coarse particle separation, high-frequency sieves for micron-level fine filtration, and vibrating screens for efficient processing of viscous materials.

Applicable materials for paint for filter sieve

The materials applicable to paint for filter sieve cover all kinds of liquids and suspended solids involved in the production and application of paint. Paint can be applied to many different types of materials, such as wood, metal, concrete, plastic, etc.

Water-based paint Suitable for a variety of surfaces such as wood, gypsum board, concrete, stone, etc.

|

Water-based paint |

Suitable for a variety of surfaces such as wood, gypsum board, concrete, stone, etc. |

|

Oil-based paint |

Usually used on wood, metal and concrete surfaces. |

|

Acrylic paint |

Can be used on various surfaces such as wood, metal, plastic, etc. |

|

Epoxy resin paint |

Suitable for surfaces such as metal, concrete, floor, etc. |

|

Polyurethane coating |

usually used on surfaces such as metal, wood, and fiberglass. |

What is the role of filter sieves in paint production?

Impurity filtration: remove mechanical impurities (such as sand particles, metal debris), undispersed pigment agglomerates or filler particles mixed in during the paint production process to avoid affecting the appearance of the coating (such as particles, brush marks) and performance.

Control fineness: Paint for filter sieve ensures that the fineness of the paint meets the process requirements (such as latex paint, ink and other products that are sensitive to fineness), and improves the gloss and adhesion after film formation.

Stabilize quality: Filtration can reduce quality fluctuations between batches, especially in the color paste mixing and compounding process, to ensure the consistency of paint color and performance.

Paint for filter sieve selection

When selecting Paint for filter sieve equipment, high-frequency sieves are preferred for thick paints, while filter sieves can be used for medium viscosities, while vibrating sieves are more suitable for thin paints.

High-frequency sieves are primarily used for thick paints and are ideal for applications requiring fast, efficient filtration. These devices use high-frequency vibrations to rapidly flow the paint across the sieve surface, achieving uniform filtration. Depending on the equipment configuration, hourly throughput can vary based on the paint viscosity and sieve mesh specifications, generally achieving high efficiency. Furthermore, high-frequency sieves can be configured with one or two outlets to meet the needs of different production lines, flexibly adapting to production output and process requirements.

Filter sieves are suitable for filtering medium-viscosity paints, effectively removing particulate matter and ensuring uniform and smooth paint flow. Depending on the application scenario and production requirements, different types of filter sieves can be selected, such as high-base, mobile, silo, or valve-bar models, for ease of operation and space optimization. The filtration capacity is affected by the paint viscosity and sieve mesh size, and can be adjusted based on actual production conditions to meet the filtration needs of small to medium batches or continuous production.

The rotary vibrating screen primarily processes thin coatings. Through rotational vibration, the coating is evenly spread across the screen, efficiently removing impurities. Compared to high-frequency screens and conventional filter screens, the rotary vibrating screen typically has a higher throughput, making it suitable for high-volume production or rapid filtration needs. The equipment can be equipped with screens of varying mesh sizes to precisely control filtration accuracy and ensure consistent coating quality.

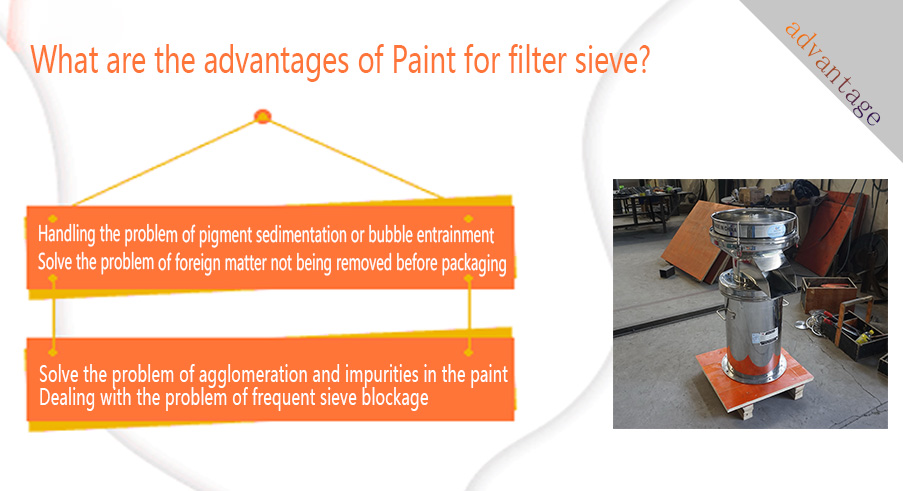

What are the advantages of Paint for filter sieve?

Paint for filter sieve can remove pigment precipitation, bubbles and foreign matter, improve the fineness of the coating film, prevent blistering, crusting and mildew, and at the same time improve filtration efficiency and reduce clogging through the appropriate screen material and mesh size.

Handling the problem of pigment sedimentation or bubble entrainment: The paint is left to stand for a long time during the screening process, and the pigment is precipitated or mixed with air, affecting the filtration quality. Use a filtering device with a stirring function or cooperate with a dynamic screening system.

Solve the problem of foreign matter not being removed before packaging: If it is not fully filtered before filling, impurities are prone to sedimentation, mildew, foaming, etc. Closed pipeline transportation with paint for filter sieve can avoid pollution.

Solve the problem of agglomeration and impurities in the paint: Insufficient pigment dispersion, crusting during storage, reaction residues, etc., resulting in the paint being not delicate, and the coating film having a granular feel and pitting. Use a paint for filter sieve with a suitable mesh size (e.g. 80-120 mesh for latex paint) to effectively intercept large particles and foreign matter.

Dealing with the problem of frequent sieve blockage: Viscous paint or sand-containing systems (e.g. floor paint, anti-corrosion paint) easily adhere to the sieve surface, resulting in difficulty in passing through the sieve and low efficiency. Reasonably select the sieve material (e.g. polyester mesh, stainless steel woven mesh), reduce adhesion, control the viscosity of the paint, and properly dilute or circulate before filtering.

Paint for filter sieve mesh size

|

Mesh size |

pore size(μm) |

applicable coating type |

typical impurities/particles |

|

60-80 mesh |

250-180 |

building putty, primer |

coarse particles, fiber agglomerates, undispersed fillers |

|

100-150 mesh |

150-100 |

ordinary latex paint, industrial primer |

pigment agglomeration (>100μm) |

|

200-325 mesh |

75-45 |

topcoat, metal paint, wood paint |

grinding residual particles (50-75μm) |

|

400-500 mesh |

38-25 |

automotive coating, nano coating, high gloss varnish |

ultrafine agglomerates (such as nano titanium dioxide) |

The mesh size of the paint filter sieve is the core parameter for measuring the size of the sieve aperture, which directly affects the filtration accuracy of the paint and the quality of the finished product. The mesh size is defined as the number of holes per square inch on the sieve. The higher the mesh size, the smaller the aperture, and the finer the particles that can be filtered.

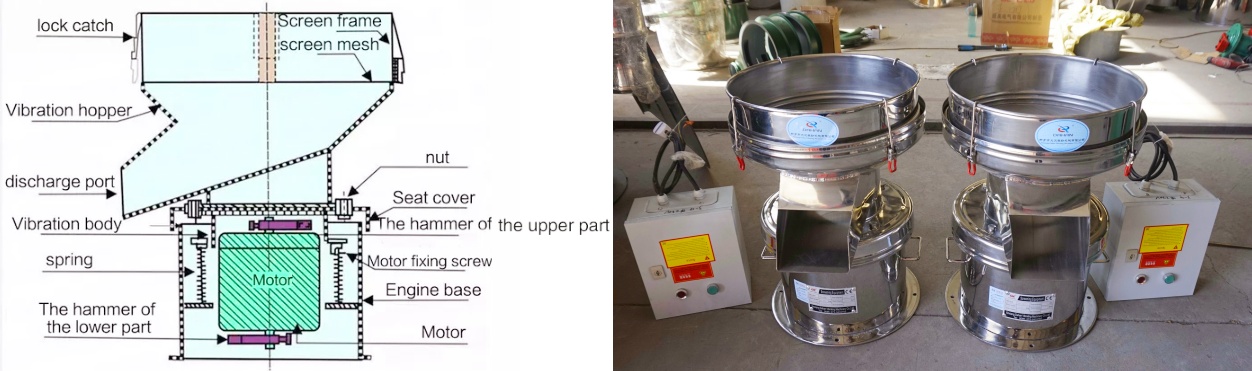

What is the working principle of Paint for filter sieve?

The working principle of Paint for filter sieve is to use the pore size of the sieve or filter material to separate impurities, particles or unevenly dispersed materials in the paint from qualified paint to achieve purification and classification.

①The pore size of the sieve/filter material as the core component determines the filtration accuracy. If the particles in the paint are larger than the sieve aperture, they will be retained (i.e., impurities); particles less than or equal to the aperture will pass through the sieve and become qualified paint.

②Separation purpose: Remove mechanical impurities (such as sand, metal chips), undispersed pigment agglomerates, flocculants, etc., to ensure that the paint fineness meets the standard.

What are the Application of Paint for filter sieve?

Paint for filter sieve is applied throughout the entire process: preventing impurities from mixing during production, removing undissolved particles during color mixing preparation, secondary filtration during filling and transportation, and final filtration during construction to ensure a smooth and flawless surface.

Paint production stage: before the emulsion, resin, and pigment slurry are put in, the packaging impurities and large particles are removed through the filter sieve to prevent mixing into the production line. Latex paint and water-based paint are passed through a sieve (generally 80 to 300 mesh) before filling to remove fine agglomerates.

Paint coloring and preparation stage: Pigments or additives may bring in undissolved particles, which need to be removed with a filter sieve to avoid color difference and sedimentation of the finished product. Paint for filter sieve can prevent bubbles and dry substances from appearing during the mixing process, affecting batch stability.

Paint filling and transportation stage: Secondary filtration before filling, it is necessary to pass through the sieve again to prevent foreign matter left over from production from entering the packaging barrel; during storage and transportation, viscous paint is prone to crusting or precipitation, and a filter sieve is used to separate impurities to ensure subsequent construction performance.

Paint construction stage: Use a fine sieve (generally 150~300 mesh) to filter the paint to remove lumps or particles; some viscous paints or heavy anti-corrosion paints need to be temporarily filtered on site to ensure a smooth and flawless surface.

In the paint industry, paint for filter sieve runs through all stages from raw material processing, production and processing, product filling to construction application. It is one of the key equipment to ensure paint quality, improve construction efficiency and reduce after-sales problems. If you need more specific product recommendations or technical details, please provide the coating type (such as water-based, oil-based) or filtration accuracy requirements, we can further help you analyze, and Dahan Machinery also supports free trial.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Granules, powders, and paddle materials can be used.

-

Meet the needs of large-scale and high-precision screening

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical and chemical properties of...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification, impurity removal or particle...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification, impurity removal or particle...

-

Tea seed grading linear vibrating screen

The tea seed grading linear vibrating screen is a key equipment used in the tea processing field for screening and grading tea seeds. Its core function is to achieve...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.