Coconut shell linear vibrating screen

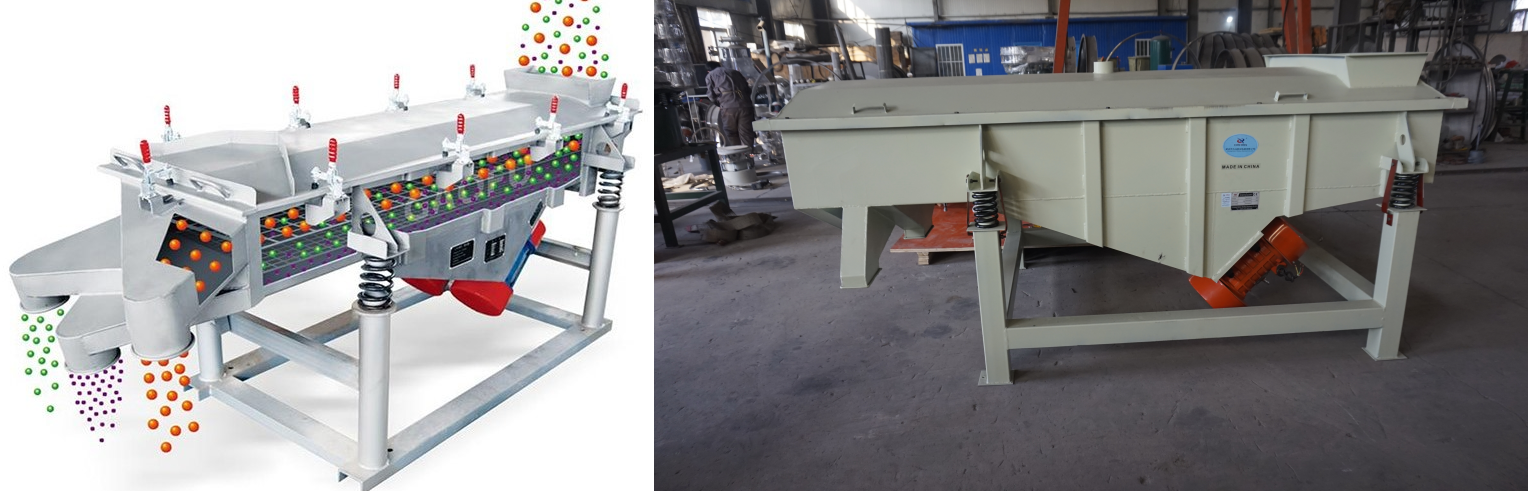

Coconut shell linear vibrating screen is designed to solve the problem of coconut shell screening. It adopts a multi-layer design, which can achieve the separation of different particle sizes and effectively process irregularly shaped and fiber-rich coconut shell materials. Recommended screening meshes include: 4 mesh (above 4.75mm, suitable for coarse particle separation), 8 mesh (2.5mm-4.75mm, suitable for most processing), 12 mesh (1.68mm-2.5mm, suitable for fine particle screening), 20 mesh (0.85mm-1.68 mm, suitable for powder making), etc.

The core function of the coconut shell linear vibrating screen

The core function of the coconut shell linear vibrating screen is to separate and grade coconut shell particles of different sizes through vibration to meet the requirements of subsequent processing technology. Specifically, it may include:

① Particle size classification: Separate the crushed coconut shell into particles of different sizes, such as coarse shell, medium shell, and fine shell.

② Remove impurities: Remove impurities such as soil, sand, and fiber that may be mixed in the coconut shell to improve the purity of the coconut shell.

③ Dehydration: If the moisture content of the coconut shell raw material is high, the linear vibrating screen can also play a certain dehydration role during the transportation and screening process.

What is the working principle of the coconut shell linear vibrating screen?

The motor drives the vibrator through a belt or direct connection to generate an exciting force.

The two vibrators rotate synchronously in opposite directions, causing the screen box to produce linear motion in the horizontal direction.

The coconut shell particles are subjected to the vibration force on the screen surface, and are constantly thrown up and down, while jumping forward along the straight line of the screen surface.

As the coconut shell particles of different sizes move on the screen surface, the particles smaller than the screen hole will pass through the screen and fall to the lower layer, while the particles larger than the screen hole will continue to move on the screen surface and eventually be discharged from the discharge port, thereby achieving size classification.

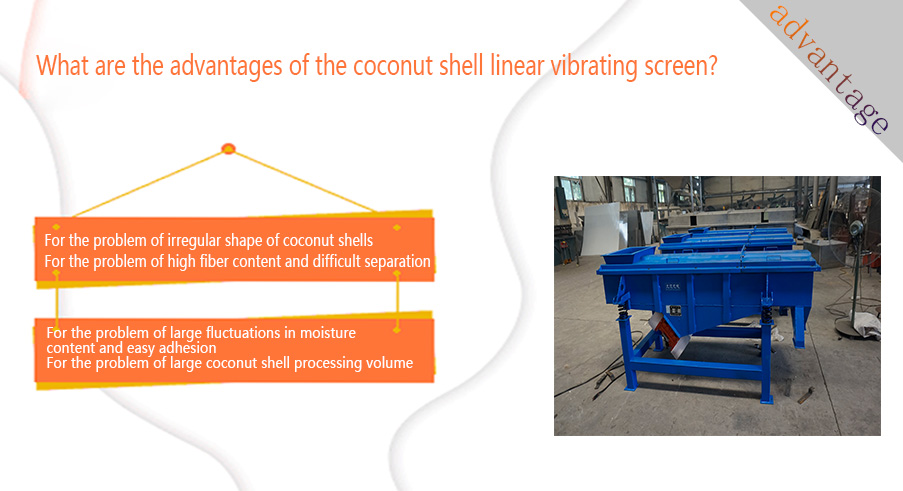

What are the advantages of the coconut shell linear vibrating screen?

For the problem of irregular shape of coconut shells: After being crushed, coconut shells usually present irregular shapes such as flakes and fibers. Using a larger screen inclination angle can help the material move forward faster and reduce the risk of entanglement and accumulation.

For the problem of high fiber content and difficult separation: Coconut shells are rich in fibers, which have a certain toughness and are not easy to pass through the screen holes. They are easy to form clumps, which affect the falling of fine particles. Use multi-stage screening to gradually separate particles of different sizes to avoid blockage caused by separating a large number of fibers at one time.

For the problem of large fluctuations in moisture content and easy adhesion: fresh or improperly processed coconut shells may have a high moisture content, and wet material particles are easy to stick together and block the screen holes. Use a screen with a self-cleaning function, such as an elastic screen or a screen with an anti-blocking design to reduce the adhesion of wet materials.

For the problem of large coconut shell processing volume: The processing volume of coconut shells is usually large, and the screening equipment needs to have a higher processing capacity and efficiency. Coconut shell linear vibrating screens are usually designed to be larger, with a wider screen surface and a larger processing capacity.

Recommended mesh size of coconut shell linear vibrating screen

|

Application scenario |

Purpose |

Recommended mesh size range (mesh) |

Particle size range (μm) |

|

Rough processing and pretreatment |

Remove larger impurities and preliminarily classify coarse and fine materials |

4-20 |

4750-850 |

|

Preparation of raw materials for activated carbon production |

Screening coconut shell particles suitable for carbonization and activation |

10-40 |

2000-425 |

|

Preparation of biomass fuel or filler |

Processing into biomass fuel of a certain particle size or using as filler |

20-80 |

850-180 |

|

Preparation of coconut shell powder |

Crushing into fine powder for food, cosmetics or industrial applications |

80-325+ |

180-45 and below |

|

Grading of coconut shell waste recycling |

Grading waste for different purposes |

Flexible selection (4-80) |

4750-180 |

Application of coconut shell linear vibrating screen

Production of coconut shell activated carbon: In the process of preparing activated carbon from coconut shell, the crushed coconut shell particles need to be screened to obtain raw materials with suitable particle size. The linear vibrating screen can accurately classify coconut shell particles according to different particle sizes, providing materials with uniform particle size for subsequent activation and other processes, which helps to improve the quality and performance of activated carbon.

Coconut shell fiber processing: Before coconut shell fiber extraction, coconut shells need to be crushed and screened. The linear vibrating screen can separate coconut shell particles of different sizes, which is convenient for the subsequent fiber extraction process. For finer coconut shell particles, they can be further processed into products such as coconut bran; while larger particles can be used for other purposes, such as fuel or further crushing.

Coconut shell linear vibrating screen is an important grading equipment in coconut shell processing. It efficiently separates coconut shell particles of different sizes through linear vibration, removes impurities, and performs a certain amount of dehydration, providing the necessary particle size control and raw material purification for subsequent deep processing and resource utilization of coconut shells.

-

Potato Starch Vibrating Screen

Granules, powders, and paddle materials can be used.

-

Granules, powders, and paddle materials can be used.

-

Meet the needs of large-scale and high-precision screening

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical and chemical properties of...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification, impurity removal or particle...

-

Tea seed grading linear vibrating screen

The tea seed grading linear vibrating screen is a key equipment used in the tea processing field for screening and grading tea seeds. Its core function is to achieve...

-

EAA polymer powder sieving machine

EAA polymer powder sieving machine is an automated equipment designed for high-precision sorting, ensuring that the EAA polymer powder has uniform particle size....

-

Glutinous rice ball coating machine

Glutinous rice ball coating machine is designed for all kinds of quick-frozen glutinous rice ball, aiming to achieve efficient and uniform powder adhesion. The equipment....

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.