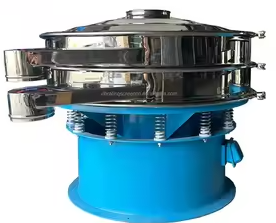

White sugar powder screening machine

What is White sugar powder screening machine?

White sugar powder screening machine can process sugar powder in the range of 30-150 meshes, which is suitable for various types of sugar materials. Sugar can be divided into dry sugar and wet sugar according to its physical properties such as particle size, fluidity and viscosity. Dry sugar, such as crystallized white sugar, has large particles, good fluidity and low viscosity, and is suitable for rapid screening of medium and coarse particles using a straight screen, with a common mesh size of 40-120 meshes. Wet sugar or fine sugar, such as soft white sugar and powdered sugar, has fine particles, is easy to absorb moisture and agglomerate, has poor fluidity and high viscosity, and is prone to blockage during screening. This type of material is suitable for using a filter screen or an ultrasonic vibrating screen, with a screening range of up to 80-150 meshes. In particular, the ultrasonic screen can effectively solve the problem of blockage through high-frequency micro-vibration, improve screening efficiency and accuracy, and is suitable for fine processing of high-purity and fine-grained sugars.

In practical applications, there are two main purposes for screening sugar powder: one is to remove impurities, that is, to remove large crystal particles, fibers, sand and other foreign matter in the raw materials to ensure the purity of the sugar; the other is to classify. According to the production process requirements, multi-layer screens (such as 80 mesh, 100 mesh, 120 mesh) are used to accurately screen the sugar powder into three levels: coarse, medium and fine. Among them, coarse powder (80 mesh) is used for baking raw materials, medium powder (100 mesh) is suitable for candy coating, and fine powder (above 120 mesh) is used for high-end beverages or pharmaceutical excipients.

White sugar powder screening machine type selection

Common White sugar powder screening machine on the market include linear screens, filter screens, plastic vibrating screens, and ultrasonic vibrating screens. All of the above equipment can remove impurities, filter, or grade powdered sugar.

Linear screens are usually equipped with 1-2 layers of screens with a screening mesh range of 20-200 mesh and an hourly output of 1-5 tons. They are suitable for particle size classification of crystalline sugars such as white sugar and rock sugar. Filter screens mostly adopt a single-layer design with a screening accuracy of 40-300 mesh and a lower output (0.5-2 tons/hour). They are specially used for fine impurity removal of powdered sugar. Plastic vibrating screens are made of PP material and are equipped with 1-3 layers of screens with a mesh range of 30-150 mesh and an output of 1-3 tons/hour. They are suitable for screening glucose and lactose with anti-corrosion requirements. Stainless steel linear screening machines are equipped with 1-5 layers of metal screens with a screening mesh range of 10-400 mesh and a processing capacity of up to 0.5-10 tons/hour. It can handle multi-level classification of various sugars such as granulated sugar and brown sugar; the ultrasonic vibrating screen achieves high-precision screening through high-frequency micro-vibration. The single-layer screen can reach 500 meshes and the production capacity is 0.1-1 tons/hour. It is particularly suitable for ultra-fine screening of sugar powder that is easy to agglomerate (such as frosting sugar and syrup crystal powder).

White sugar powder screening machine specifications

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

White sugar powder screening machine advantages

White sugar powder screening machines offer numerous advantages in the powdered sugar processing process, effectively removing impurities and ensuring a fine and uniform powdered sugar, thereby improving production efficiency and product quality. For high-volume processing, fast unloading, and continuous operation, a linear screen can be used for coarse screening or preliminary impurity removal. If there is liquid in the powdered sugar, a filter screen can be used. For equipment that is corrosion-resistant, anti-sticking, avoids metal contamination, and is lightweight and easy to clean, a plastic vibrating screen can be used. For sticky powdered sugar, an ultrasonic vibrating screen is preferred because it prevents screen clogging. Furthermore, this device is advantageous for ultrafine powdered sugars such as frosting and syrup crystals, eliminating clogging issues and improving screening accuracy, making it suitable for high-precision sugar processing.

Selection of screening schemes for sugar powder in different states

Different screening methods are recommended based on the physical properties of the powdered sugar. For wet sugar with a high moisture content, an ultrasonic vibrating screen is recommended. Because wet sugar is very viscous, traditional screening equipment can easily clog, but the high-frequency vibrations of ultrasonic waves effectively address this problem. For dry powdered sugar, either a conventional vibrating screen or an ultrasonic vibrating screen can be used, depending on the production volume and particle size requirements. Conventional vibrating screens are low-cost and suitable for processing coarse powdered sugar with a mesh size of 20-100. Regarding mesh size selection, a 40-100 mesh screen is typically used for ordinary white granulated sugar, while a 200-400 mesh screen is recommended for ultrafine powdered sugars like icing sugar. Due to the high viscosity of wet sugar, an 80-200 mesh screen is recommended; a higher mesh size increases screening difficulty. For soup powder products, a 60-120 mesh screen is generally sufficient for most applications. Conventional vibrating screens are generally suitable for coarse screening below 80 mesh, while ultrasonic vibrating screens are recommended for fine screening above 80 mesh.

White sugar powder screening machine supplier

White sugar powder screening machine supplier Our factory has over 15 years of production experience, and our engineers can customize solutions based on the characteristics of white sugar powder and customer requirements. Our equipment is made of stainless steel and meets production standards, allowing for trial runs with raw materials. With numerous successful production cases, we are a reliable choice for processing companies.

White sugar powder screening machine solution

For white sugar powder screening machine solutions, if a single line requires a throughput of 200-500 kg/h, a single double-deck vibrating screen is recommended. For throughputs of 1-3 t/h, a linear vibrating screen or multiple machines in parallel is recommended to avoid overloading the equipment and resulting in incomplete screening. Specific throughput requirements can be determined by discussing with the supplier to select the appropriate equipment model.

White sugar powder screening machine plays an important role in the screening process of sugar. Ordinary vibrating screens can be used for dry sugar to meet the needs of conventional particle screening; and in the face of wet sugar, high-viscosity sugar powder, or scenes requiring high-precision screening, ultrasonic vibrating screens are recommended. Its advantages of "fast netting and no net blocking" can effectively guarantee the screening quality. Mastering the physical properties and mesh range of sugar powder and reasonably matching the screening equipment are the key to improving the quality of sugar powder and optimizing production efficiency.

-

Hemp core powder vibrating screen

Hemp core powder vibrating screen is a device used to screen and separate fine particles such as hemp ...

-

Vibro Sifterfor Powdered Sugar

Introduction of Powdered SugarVibro Sifter Powdered sugar vibro sifter is a device for screening suga ...

-

Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine sieving system consists of ultrasonic resonance power sourc ...

-

3D Printing Powders Vibrating Sieve

Maintain the size of the mesh port and stabilize the screening accuracy Model DH400-DH2000 Capacity 1 ...

-

Powder sifter machine graphite powder

Powder sifter machine graphite powder is used for screening. The screen material is usually 316L stai ...

-

Fine iron powder Sieving Machine

Fine Iron Powder Sieving Machine typically sieving between 100 and 500 mesh (approximately 150 to 30 ...

-

Swing Vibrating Screen Screening Petroleum Coke Powder

Swing Vibrating Screening Petroleum Coke Powder is designed to process fine, dusty, and potentially s ...

-

Ultrasonic Vibrating Screen Sieve Fine Powder

Ultrasonic Vibrating Screen Sieve Fine Powder is designed to address the sieving of fine, sticky, and ...

-

Powder Sieve Machine Price

Powder Sieve Machine is an industrial equipment used to separate and classify various powder raw materials by particle size...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.