Fine iron powder Sieving Machine

What is a Fine Iron Powder Sieving Machine?

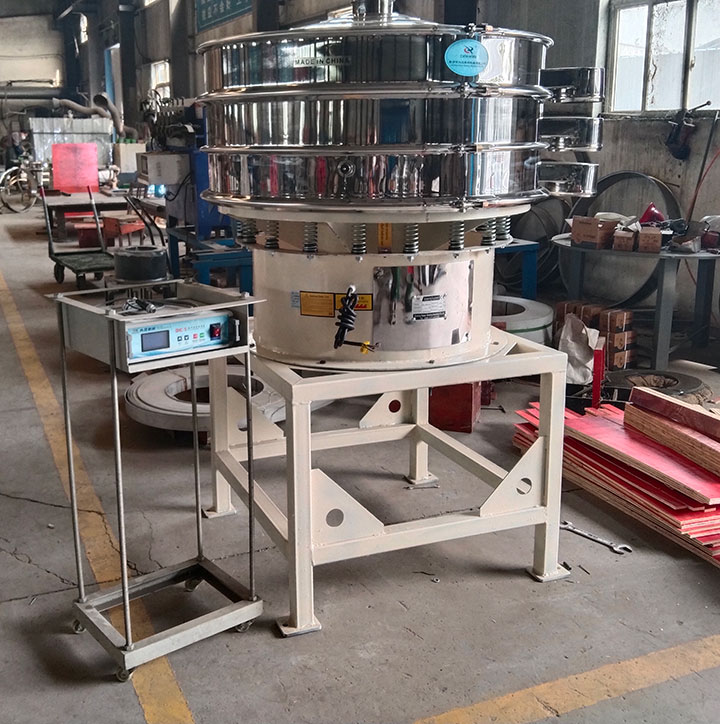

Fine iron powder Sieving Machine can process fine iron of varying mesh sizes. Four common types of equipment are used depending on the purpose of sieving fine iron powder: ultrasonic vibrating screens for ultrafine iron powders; rotary vibrating screens for multi-size classification; airflow screens for high-viscosity/high-humidity iron powders and easily oxidized iron powders; and linear vibrating screens for large-scale iron powder production lines. Screening throughput ranges from tens of kilograms to several tons per hour, depending on the machine model and powder fineness. The Fine Iron Powder Sieving Machine typically sieving between 100 and 500 mesh, with ultrafine powders reaching micron levels.

The Fine Iron Powder Sieving Machine employs a 2- to 6-layer vibrating screen structure. Each layer of screen has progressively smaller mesh sizes from top to bottom, achieving graded sieving from coarse to fine. The upper screen intercepts larger particles or impurities, the middle layer separates medium-sized iron powder, and the bottom screen separates the finest iron powder with the highest purity. Different mesh sizes can be selected for each layer to meet production needs, such as 20-60 mesh for the upper layer, 80-200 mesh for the middle layer, and 300-500 mesh for the lower layer, enabling multi-stage fine sieving.

Sieving Steps of a Fine Iron Powder Sieving Machine

The sieving steps of a fine iron powder sieving machine are as follows: First, preparation includes selecting a sieve with a suitable mesh size (such as 200 mesh, 325 mesh, etc.), installing and checking the equipment's sealing, and connecting the dust collection system. Then, set parameters such as vibration frequency, amplitude, or ultrasonic power according to the material characteristics. Next, use a screw feeder or manual feeding to evenly and continuously feed the iron powder into the sieving machine's inlet, avoiding instantaneous overload. After starting the equipment, the powder is separated and stratified on the sieve surface. Fine particles pass through the sieve and become the undersize (qualified fine powder), while coarse particles and impurities are discharged as the oversize. Finally, collect the undersize and oversize separately, and clean the equipment promptly after operation to prevent iron powder oxidation and cross-contamination.

What types of screening equipment are used for fine iron powder sieving machines?

Fine iron powder sieving machines include the following types: ultrasonic vibrating screens are suitable for ultrafine iron powder; rotary vibrating screens are suitable for multi-size classification of fine iron powder; airflow screens are suitable for high-viscosity, high-humidity, and easily oxidized iron powders; and linear vibrating screens are suitable for large-scale fine iron powder production lines.

Ultrasonic Fine Iron Powder Sieving Machine: Breaks down fine iron powder agglomerates, eliminates screen clogging, and provides precise grading.

The equipment can process 80-1200 mesh fine iron powder, which is 40%-60% more accurate than traditional vibrating screens. The ultrasonic screen cleaning efficiency is 3-5 times that of traditional bouncing balls, with a screening rate of over 95%. 316L stainless steel material is optional.

Rotary Vibrating Screen Fine Iron Powder Sieving Machine: Simultaneously grading with multiple screens for both impurity removal and filtration.

This equipment can process fine iron powder of 20-800 mesh. The number of screen layers and the size of the mesh can be flexibly adjusted. Under the same output, the floor space is only 1/3 of that of a linear screen. The quick-release screen replacement only takes 5-10 minutes.

Airflow Screen Fine Iron Powder Sieving Machine: Airflow-assisted screening breaks up agglomerates and preserves material properties.

This equipment processes 40-600 mesh fine iron powder with high viscosity, high humidity, or easy agglomeration. The equipment uses airflow suspension to thoroughly break up agglomerates and prevent "false screening". The material is not subjected to violent collisions or compression, which reduces oxidation and maintains its original properties.

Linear Vibrating Screen Fine Iron Powder Sieving Machine: Multi-layer, high-capacity continuous screening, suitable for assembly lines.

This equipment is used for large-scale processing of 20–500 mesh iron powder, with a capacity of 10–50 tons/hour. It can be connected to grinding and pressing equipment. Employing a linear motion trajectory, screening efficiency is increased by 30%–50%. Equipped with spring damping, it features low noise, few malfunctions, and is suitable for continuous operation.

Fine iron powder Sieving Machine specifications

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

What are the benefits of using a Fine Iron Powder Sieving Machine?

The Fine Iron Powder Sieving Machine addresses the tendency of fine iron powder to agglomerate and clog the screen. By optimizing the vibration frequency and adding bouncing balls and ultrasonic cleaning devices, it reduces screen clogging, increasing the fine iron powder sieving rate by 30%-50%. It also maintains screening accuracy within ±2%, preventing subsequent product quality fluctuations. Compared to traditional screening, which requires frequent manual operation and is prone to errors, the Fine Iron Powder Sieving Machine enables automated and continuous operation, reducing labor input and protecting workers from long-term exposure to fine iron powder dust, thus protecting their health. Furthermore, its fully enclosed design prevents fine iron powder from flying during screening, resulting in a material recovery rate of over 98%, effectively reducing raw material loss.

Application of Fine Iron Powder Sieving Machine in Iron Powder Industry

In the powder metallurgy industry, the Fine Iron Powder Sieving Machine serves as a core pretreatment device, screening fine iron powder with uniform particle size to ensure consistent density in pressed green compacts, reduce sintering deformation and cracking, and improve the mechanical properties of the finished product.

In the magnetic materials production industry, the Sieving Machine classifies fine iron powder used in the production of permanent magnets and soft magnetic materials, with different mesh sizes corresponding to products with different magnetic properties.

In the chemical and food additive industries, the Sieving Machine removes impurities from fine iron powders for specialized applications, ensuring purity that meets standards and avoids compromising product safety or chemical reaction efficiency.

In the metal surface treatment industry, Fine Iron Powder Sieving Machine selects fine iron powder of appropriate particle size (used for polishing and rust removal of metal parts), ensuring uniform polishing and preventing coarse particles from scratching the metal surface.

Fine iron powder Sieving Machine Suppliers

Consider Dahan Vibration Machinery when choosing a fine iron powder sieving machine. We can recommend ultrasonic or bouncing ball devices based on dry, slightly greasy, damp, or easily agglomerated iron powder. For flammable and explosive iron powders, we have standard explosion-proof motors. If you require specialized dimensions, inlet and outlet locations, or fully automated docking, Dahan Machinery can customize the machine. We are committed to providing professional technical advice and proven solutions.

Designed specifically for the characteristics of fine iron powder, the Fine iron powder Sieving Machine, with its wide mesh size range, flexible output options, durable materials, and rational structure, has become a crucial piece of equipment for fine iron powder processing. The appropriate equipment can be selected based on the specific mesh size requirements of the fine iron powder. The material contact parts of the fine iron powder sieving machine can be made of 304 or 316 stainless steel, the frame can be made of carbon steel or stainless steel, and the screen can be made of stainless steel or nylon. Through its unique features, this equipment provides a powerful boost to improving the quality and output of fine iron powder in industries requiring it.

-

Powder sieving machine is designed for high volume sieving of powders to remove oversized contaminants ...

-

metal powder sieving machine sends ultrasonic waves to the surface of the sieve to prevent clogging or damage of the sieve...

-

Battery Anode Materials Vibrating Sieve

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

-

Graphite Powder Sieving Machine

Graphite powder sieving machine is specially developed to solve the problem of graphite powder sieving...

-

Standard test sieve price

Standard test sieve price usually ranges from US$20 to US$300, depending on the size, material and accuracy level...

-

Atomized Iron Powder Vibrating Screening Machine

Atomized iron powder vibrating screening machine is a type of equipment used to separate and classify atomized iron powder...

-

High -frequency vibration sieve for latex paint filter

High -frequency vibration sieve for latex paint filter is a filtration device designed for high-viscosity liquid systems such as water-based paints ...

-

Vibro Sifter Magnesium Oxide

Vibro Sifter Magnesium Oxide refers to the process of using a vibro sifter to grade and screen magnesium oxide powder...

-

Electric Automatic Sieve Shaker Vibrating Sieve Machine

Electric Automatic Sieve Shaker Vibrating Sieve Machine are commonly used in laboratories and industrial production...

-

Tumbler Screening Machines

Tumbler Screening Machines are available in carbon steel, stainless steel, and special steel to meet...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.