Vibrating Sieve Rapeseed

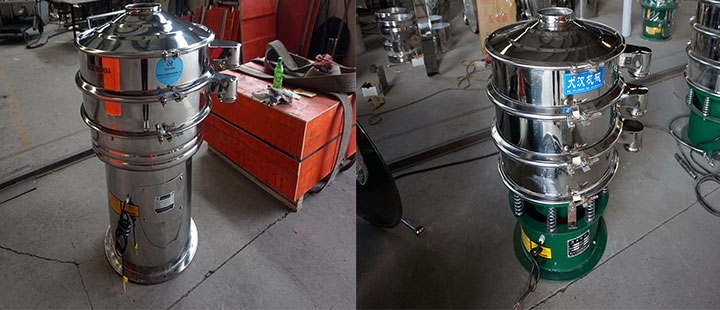

Vibrating Sieve Rapeseed uses the excitation force generated by a vibrating motor to create three-dimensional vibrations on the screen, enabling precise rapeseed grading and impurity removal. This equipment is suitable for rapeseed materials with a moisture content below 12% and a particle size between 1.5 and 2.5 mm, effectively processing raw materials with high impurity content. The standard configuration offers an adjustable screen range of 40-100 mesh, typically using two to four screen layers, capable of achieving three to five grades of grading depending on demand. Its processing capacity ranges from 0.5 to 5 tons per hour. Rapeseed, a cruciferous crop, has spherical or oval kernels with an oil content of 37%-46%, but its surface is susceptible to impurities such as straw debris, dirt, and stones. The equipment's fully enclosed structure effectively prevents dust from escaping during the sieving process.

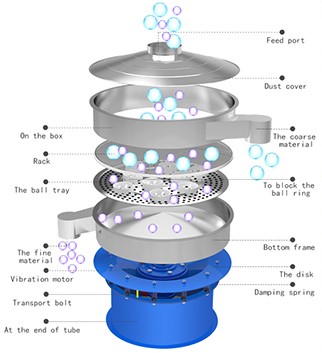

Vibrating Sieve Rapeseed consists of multiple components: a feed inlet for feeding, a dust cover to prevent dust contamination, a support frame, a ball tray, and a structure for blocking the ball rings. The bottom frame provides a base for separating coarse and fine materials. A vibrating motor powers the vibrating screen, while transport bolts are used for transport. The tube ends also contain components, a plate, and damping springs for vibration reduction.

How the Vibrating Sieve Rapeseed Works

Vibrating Sieve Rapeseed uses dual vibrating motors as excitation sources, generating a directional, composite vibration (typically at a 45° angle), which creates a spiral motion across the screen surface. This motion creates a "bouncing and sliding" motion in the rapeseed, allowing smaller impurities and broken seeds to fall through the screen mesh while intact rapeseed moves forward along the screen surface to the discharge outlet. The equipment's elastic screen tensioning system and rubber ball cleaning device effectively prevent screen clogging and maintain stable screening efficiency. The advanced variable frequency control system allows the operator to precisely adjust the vibration frequency and amplitude based on material characteristics to meet the screening requirements of different rapeseed varieties. The equipment operates at a noise level below 75 decibels, and its power consumption is approximately 30% lower than traditional screening equipment.

Vibrating Sieve Rapeseed Technical Parameters

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Vibrating Sieve Rapeseed Equipment Advantages

Vibrating Sieve Rapeseed offers numerous advantages: its vibration pattern separates rapeseed particles of varying sizes, achieving a screening efficiency exceeding 98.5%. Impurity removal exceeds 90%, significantly improving the quality of the finished product. Its modular design reduces screen replacement time to less than 15 minutes, improving maintenance efficiency by 60% compared to traditional screening equipment. The equipment is constructed of 304 stainless steel, making it corrosion-resistant and easy to clean, meeting food safety standards. Another significant advantage is its low operating noise and adjustable vibration amplitude, allowing it to flexibly adapt to various production environments and material characteristics.

What are the uses of the Vibrating Sieve Rapeseed?

Vibrating Sieve Rapeseed is widely used in various stages of rapeseed processing: in the pretreatment stage, it is used to remove large impurities such as stones and clods; in the post-cleaning process, it is used to grade and remove immature seeds and fine impurities; and in the final cleaning process before oil extraction, it ensures the purity of the raw material. Beyond rapeseed, the equipment can be used in various applications with adjustable parameters. In the agricultural sector, it is commonly used to screen granular materials such as sesame seeds, crushed peanuts, beans, and corn kernels. In the food processing industry, it can be used to screen materials such as powdered seasonings, powdered sugar, and coffee granules. In the chemical and pharmaceutical industries, this equipment is also used to screen a variety of materials, including chemical raw materials, pharmaceutical powders, and granules.

The Vibrating Sieve Rapeseed is a high-performance vibrating screen designed for screening granular materials, particularly rapeseed. It improves screening efficiency and product purity, simplifies processing, reduces labor costs, and provides reliable support for the primary processing of agricultural products. Its rational structure, simple operation, high screening efficiency, and excellent scalability and adaptability can meet the screening needs of various scales and industries. With the large-scale development of the grain and oil processing industry, the role of vibrating screen equipment will become increasingly important. The Vibrating Sieve Rapeseed is not only a powerful tool for improving production efficiency, but also a key equipment for promoting the modernization and standardization of the rapeseed industry.

-

White sugar powder screening machine

White sugar powder screening machine can process sugar powder in the range of 30-150 meshes ...

-

Vibrating Screen Coconut Pollen

Vibrating Screen Coconut Pollen is a screening device designed for the characteristics of coconut powder ...

-

Powder Sieve Machine Price

Powder Sieve Machine is an industrial equipment used to separate and classify various powder raw materials by particle size ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.