Vibrating Machine To Separate Baobab Pulp From It’S Seed

During the process of separating the vibrating machine to separate baobab pulp from it’S Seed, due to the special internal structure of the baobab fruit, the pulp is loose, dry, powdery or lumpy, while the seeds are hard, heavy and large in size, and the physical properties of the two are obviously different. It through vibration force. Usually 1-2 layers of vibrating screening equipment are selected, in which the upper screen has a larger aperture (such as 5-10mm) to intercept larger seeds, and the lower screen has a smaller aperture (such as 1-3mm) to screen out fine pulp powder and achieve graded screening of coarse and fine particles.

Multi-layer design of vibrating machine to separate baobab pulp from it’S Seed design helps to improve the screening accuracy and yield, while avoiding seeds entrained with pulp residues or seeds mixed in the pulp, thereby improving the efficiency of subsequent processing. The equipment is suitable for dry processing conditions, especially for the primary processing of baobab fruit that requires high separation rate and low loss.

How to sift Vibrating Machine To Separate Baobab Pulp From It's Seed?

When screening the Baobab Pulp From It's Seed using the Vibrating Machine, the pulp is mostly powdery. This can be graded through an 80- to 120-mesh sieve to obtain finer particles for further processing or nutrient extraction. The seeds, being granular, require coarse screening. Typically, a 5- to 20-mesh sieve is used to remove large impurities such as peel and stems. A 20- to 40-mesh sieve is then used to remove smaller impurities and debris to ensure seed purity. The entire screening process utilizes a vibrating machine's multi-layer screens, coupled with high-frequency vibration and self-cleaning bouncing ball technology. This allows for continuous production without screen clogging, improving subsequent processing efficiency and product quality.

What is the main purpose of the vibrating machine to separate baobab pulp from it’S Seed?

The fruit of the baobab tree is oblong, the pulp is juicy, contains organic acids and gum, and has a slightly sour taste. The seeds are wrapped in the pulp, the seed coat is thick, and the oil content is as high as 15%. After the pulp is dried, it will break into blocks, similar to dry bread crumbs. Use a vibrating screen (circular vibrating screen, linear vibrating screen) equipped with screens of different apertures. The vibrating screen separates the pulp and seeds through high-frequency vibration, and the lighter pulp fragments pass through the screen, while the heavier seeds are left on the screen.

The mesh aperture should be adjusted according to the seed size (about 1-2 cm), and a 5-10 mm aperture screen is usually selected to ensure that the seeds cannot pass through but the pulp fragments can pass through.

Adjust the vibration frequency (usually 1000-3000 times/minute) and amplitude (2-6 mm) to ensure that the pulp and seeds are effectively separated while avoiding damage to the seeds.

How does vibrating machine to separate baobab pulp from it’S Seed work?

The vibrating machine is used to separate the pulp and seeds of baobab trees. It mainly uses the mechanical energy of vibration to make the pulp and seeds inside the fruit move relative to each other, thereby achieving separation. The specific process is usually as follows:

Raw material preparation: Pre-treat the baobab fruit, such as removing the shell or preliminary crushing, so that the pulp and seeds can be separated more easily.

Vibrating screen: Put the pre-treated fruit into the vibrating machine. The vibrating machine generates high-speed vibration through the motor drive, forming an up-down or multi-directional vibration force. Due to the different density, size, and hardness of the pulp and seeds, vibrating machine to separate baobab pulp from it’S Seed causes the two to produce different motion responses. The pulp is softer and has stronger adhesion, and is thrown or shaken off under vibration, while the seeds are harder and usually remain intact.

Screening and grading: Vibrating machine to separate baobab pulp from it’S Seed is usually equipped with a screen with a suitable aperture design so that the fine particles of pulp can fall through the screen, while the seeds are left on the screen due to their larger size, thus achieving separation of the two.

Discharge collection: The separated pulp and seeds are collected from different outlets for subsequent processing or treatment.

Recommended mesh number for Vibrating machine to separate baobab pulp from it’S Seed

When using a vibrator to separate baobab pulp and seeds, choosing the right mesh number is one of the key factors, which directly affects the separation effect. The mesh number is the number of mesh holes per unit length (usually 1 inch) of the screen. The higher the mesh number, the smaller the aperture.

|

Materials |

Recommended mesh number |

Corresponding aperture (mm) |

Description |

|

Pulp powder/fine-grained pulp |

20-40 mesh |

0.42-0.85 mm |

Allows fine pulp to pass smoothly, but seeds cannot pass |

|

Coarse-grained pulp |

10-20 mesh |

0.85-2.0 mm |

When the pulp is not completely powdered, it can be separated with a coarse sieve |

|

Seed retention layer |

<10 mesh or directly use a perforated plate with an aperture of 6-8 mm |

≥2.0 mm |

Intercept complete seeds and export |

Typical configuration recommendations

Since the baobab pulp is brittle after drying and can be powdered, the particles are generally fine, and are often used to make fruit powder or beverage raw materials; while the seeds are hard and large in size, generally oval or nearly round, with a diameter ranging from 5 to 10 mm. So usually, vibrating machine to separate baobab pulp from it’S Seed will perform two layers of screening.

Upper screen: 6-8 mm aperture (equivalent to 2-3 mesh), used for preliminary separation of large seeds;

Lower screen: 20-30 mesh, used to further screen out finer pulp powder.

What can the vibrating machine to separate baobab pulp from it’S Seed be used for?

Vibrating machine to separate baobab pulp from it’S Seed is used to separate baobab pulp from seeds, and is widely used in food processing, plant extraction and seed treatment. In the food processing industry, the pulp powder after vibration screening can be used to produce nutritional supplements, energy bars, fruit powder drinks and other products, because it is rich in vitamin C, cellulose and antioxidant ingredients, and has high commercial value.

In the field of plant extraction, pure pulp is conducive to the subsequent extraction of functional ingredients, improving extraction efficiency and product purity; and in seed treatment, by removing impurities attached to the pulp, vibrating machine to separate baobab pulp from it’S Seed can be used for seed breeding, agricultural promotion or oil processing. This equipment is often used in the pretreatment link of the initial acquisition of raw materials. It is suitable for places such as agricultural product processing plants, nutritional food companies and plant raw material processing bases to achieve continuous and automated separation. It is especially suitable for large-scale primary processing operations in areas with dense baobab planting such as Africa and South Asia.

How to choose and wholesale a vibrator to separate baobab pulp from seeds

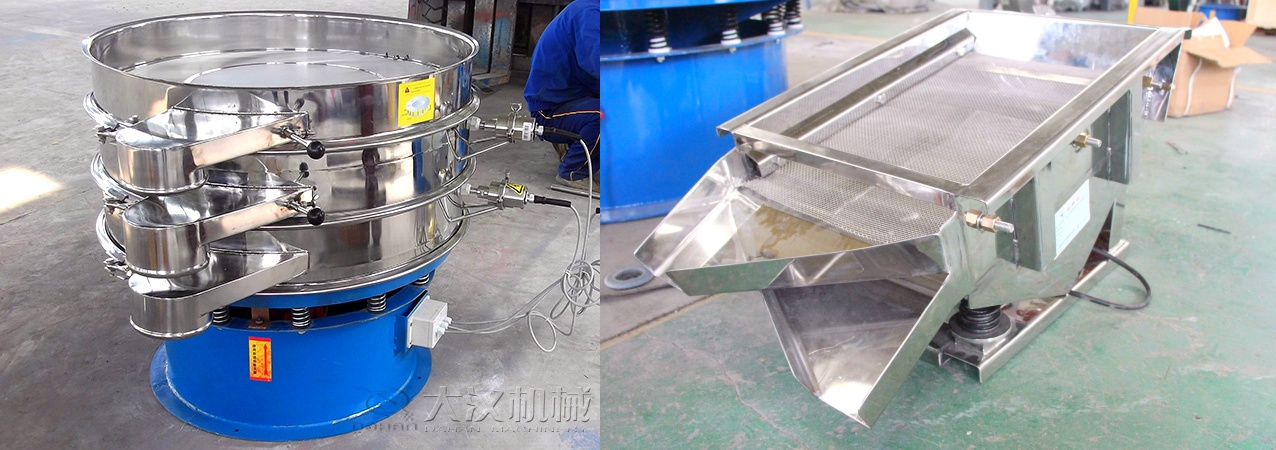

When choosing a vibrator for separating baobab pulp from seeds, you can choose a circular vibrator or a linear vibrator according to the material characteristics and processing capacity.

Circular vibrators are suitable for fine screening operations and are more suitable for separating fine pulp particles from larger seeds. Its multi-layer design can complete the screening of multiple particle sizes at one time, improving efficiency. Linear vibrators are suitable for large-scale production needs. It disperses the material evenly on the screen surface through linear motion, and is particularly suitable for rapid separation of materials with obvious differences in particle size.

When considering using a vibrator to separate baobab pulp and seeds, factors such as the required capacity, the required pulp purity, and the specific characteristics of the baobab fruit (such as dryness, size) should be considered to select the most suitable model, and the vibrating machine to separate baobab pulp from it’S Seed and suppliers on the market should be fully investigated and evaluated. The key is to balance the performance, quality, cost and after-sales service of the equipment to ensure that the equipment you choose can efficiently and stably support your baobab processing business.

Vibrating Machine To Separate Baobab Pulp From It'S Seed Case

Before a factory introduced a vibrating machine to separate baobab pulp from its seeds, workers used manual labor, resulting in low efficiency and high labor intensity. Crushed seeds were often mixed into the pulp powder, impacting product quality. After the machine was installed, dried baobab fruit was poured into the feed inlet and the pulp and seeds were automatically separated using a screen and vibration mechanism. The pulp powder passed through the screen into a collection container, while the seeds were discharged to the side. This increased the daily processing capacity of a single worker to over 30 kilograms, with pulp purity exceeding 95%.

A food processing plant now uses an airflow centrifugal vibrating screen to separate baobab fruit pulp and seeds. This machine uses a screw conveyor system to feed the crushed pulp and seed mixture into a cylindrical sieve. The centrifugal force and cyclonic propulsion generated by the high-speed impeller force the pulp powder (less than 500 mesh) through the screen and out of the fine material outlet, while coarse particles such as seeds slide along the sieve wall into the coarse material outlet. The equipment's single-layer screen design and 304 stainless steel material achieve a processing capacity of 3 tons per hour and a separation efficiency of 98.7%.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Vibrating screen for gypsum processing

The vibrating screen for gypsum processing is a screening equipment used for particle size grading, impurity removal or dehydration of gypsum...

-

Sieving Machine for Copper Electrolytic Powder

Sieving machine for copper electrolytic powder is a device used to screen copper powder obtained by electrolysis, which can...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.