Tumbler Screen Solid-Liquid

A sewage treatment customer needs to perform preliminary solid-liquid separation on aquaculture wastewater. The daily processing volume is large, and the liquid contains a large amount of floating objects and suspended solids. Solid impurities need to be separated efficiently by mechanical means to reduce the burden of subsequent processing. To meet customer needs, Dahan recommends the use of tumbler screen solid-liquid.

Workflow of tumbler screen solid-Liquid

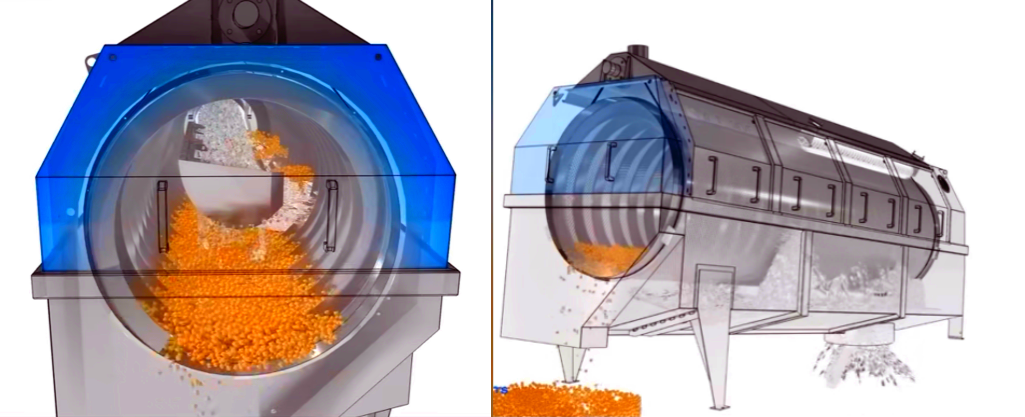

The workflow of tumbler screen solid-Liquid mainly revolves around the core function of solid-liquid separation. Relying on the rotation of the drum and the screening effect of the screen, the solid particles in the mixed liquid are intercepted, collected, and discharged to achieve continuous and efficient pretreatment.

Mixed liquids containing solid particles (such as aquaculture wastewater, food residue water, industrial slurry, etc.) are fed into the feed end of the drum screen from the feed port by pumps or gravity self-flow.

The drum is driven by a motor to rotate at a low speed (usually 10-30rpm), and the surface of the drum is a screen structure with holes (commonly 0.25mm~2mm). Liquid and solid particles with smaller particle size are discharged through the screen holes and enter the lower liquid collection tank or diversion pipe. At the same time, solid particles larger than the screen holes are intercepted by the screen surface and slowly move to the slag discharge end under the rotation of the drum and gravity.

The solid particles intercepted by the screen surface gradually move to the tail of the drum as the drum rotates, and are discharged through the slag discharge port or spiral discharge device.

Challenges

The wastewater contains a high solid content, including impurities such as feces, feed residues, and hair. Traditional screens are inefficient and easy to clog;

Continuous operation is required, and the processing capacity must meet the requirements of processing more than 60 tons of waste liquid per day;

The material has a high water content and the impurities are highly viscous. The screen is easy to clog and difficult to clean;

The working environment is humid and corrosive, which puts higher requirements on the equipment structure and material.

Solution

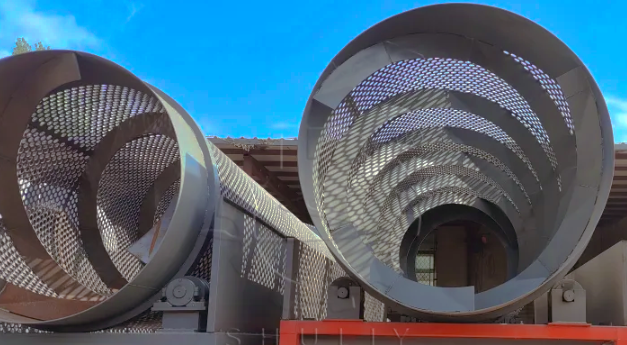

The wedge-shaped screen structure for tumbler screen solid-Liquid has a customizable screen hole size (0.25~1.5mm), is not easy to clog, and is suitable for screening high-water-content materials;

The cylinder is made of stainless steel, which has good corrosion resistance and structural strength, and is suitable for humid and harsh working conditions;

The screening process adopts a low-speed rolling + micro-inclination structure, which can operate stably and continuously, with a processing capacity of 3-5 cubic meters/hour;

Equipped with an automatic spray cleaning system, the screen surface can be flushed regularly to ensure the cleanliness of the screen and stable operation;

The filtrate and filter residue are collected separately for subsequent processing or resource reuse.

Technical parameters of tumbler screen solid-Liquid(commonly used)

|

Model |

Drum diameter (mm) |

Drum length (mm) |

Sieve size (mm) |

Processing capacity (m³/h) |

Motor power (kw) |

|

GLGS-600 |

600 |

1000 |

0.25~2.0 |

10~20 |

0.75 |

|

GLGS-800 |

800 |

1500 |

0.25~2.0 |

20~30 |

1.1 |

|

GLGS-1000 |

1000 |

2000 |

0.25~2.0 |

30~50 |

1.5 |

|

GLGS-1200 |

1200 |

2500 |

0.25~2.0 |

50~80 |

2.2 |

The customer successfully achieved the goal of stable and efficient solid-liquid separation. The drum screen runs stably every hour without obvious blockage, low operating noise and small maintenance workload. The equipment has maintained good performance since its operation, effectively intercepting most of the solid impurities, improving the efficiency of the downstream sewage treatment system, and significantly reducing the cost of manual slag removal and cleaning. The customer expressed satisfaction with the equipment structure design and operation effect, and has planned to promote its use in other treatment sites.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Vibrating screen for gypsum processing

The vibrating screen for gypsum processing is a screening equipment used for particle size grading, impurity removal or dehydration of gypsum...

-

Commercial Flour Sifter for Safety Sieving Flour

Commercial flour sifter for safety sieving flour refers to the process of using professional flour sieving equipment in an industrial pro...

-

Cow Dung Powder Seive Machine

After fermentation or crushing, cow dung often has problems such as uneven particle size, mixed impurities, and agglomeration. If it is used dir...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.