Commercial Flour Sifter for Safety Sieving Flour

The Importance of Flour Sieving

During the processing, storage and transportation of flour, it is easy for lumps (lumps after being damp), impurities (such as thread ends, paper scraps, sieve debris, etc.), foreign matter (metal shavings, insect eggs, etc.), etc. to be mixed in. If these foreign matter are not effectively removed, it will directly affect the quality and taste of the food, and even endanger the health of consumers. Therefore, safe sieving of flour is a key link in the food production process.

What is the function of a commercial flour sifter?

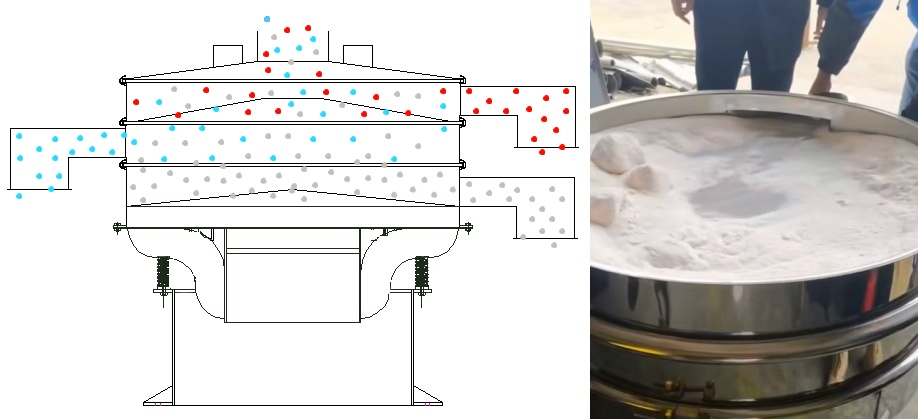

Commercial flour sifter for safety sieving flour is a professional equipment for fine processing of flour in flour processing and food production. Its core function is to grade, remove impurities and homogenize flour through mechanical vibration, screen filtration and other methods to ensure that the quality of flour meets production requirements.

① Screening by particle size: Use screens with different apertures (such as 20 mesh to 200 mesh) to filter flour particles in layers, and separate uneven flour into different particle size grades (such as extra fine powder, medium powder, and coarse powder). The screen is driven by a vibration motor or eccentric wheel to vibrate at high frequency (amplitude of about 0.5-2mm, frequency of 1500-3000 times/minute), so that the flour moves parabolically on the screen surface, and fine particles pass through the screen and fall into the next level, while coarse particles remain on the screen surface and are discharged from the discharge port.

② Remove impurities and foreign matter: intercept coarse particles, lumps, metal chips, fibers and other foreign matter mixed in the flour to avoid affecting the operation of subsequent processing equipment or the taste of food.

Use a metal mesh with a larger aperture (such as 16 mesh) to remove obvious impurities first; then use a fine screen (such as 80-120 mesh) to filter out tiny lumps or dust clusters.

Commercial flour sifter for safety sieving flour mesh number recommendation table

When using a commercial flour sifter to safely sift flour, it is very important to choose the appropriate mesh number (mesh). Different mesh numbers directly affect the particle size, taste and production requirements of the flour. The following are the recommended mesh sizes and applicable instructions for flour:

|

Mesh size (mesh) |

Corresponding particle size (μm) |

Applicable flour type |

Sieving purpose |

|

30-40 mesh |

400~500μm |

Coarse flour, grain flour |

Coarse screening, preliminary impurity removal |

|

60 mesh |

~250μm |

Ordinary wheat flour |

Remove lumps and foreign matter |

|

80 mesh |

~180μm |

Bread flour, general flour |

Standard screening, remove impurities and remove insect eggs, etc. |

|

100 mesh |

~150μm |

Cake flour, biscuit flour |

Fine screening to improve taste |

|

120-150 mesh |

~125-105μm |

High-gluten flour, special refined flour |

Ultra-fine screening to improve grading accuracy |

|

200 mesh and above |

≤75μm |

Special food powder (such as baby food) |

Ultra-fine screening |

What is the process of safely screening flour with a commercial flour sifter?

Operators should wear tight-fitting work clothes; dust masks and goggles are strongly recommended. Check before starting to ensure that there are no foreign objects (such as tools, cleaning cloths) in the equipment, no residual agglomerated flour on the screen, and the feed and discharge ports are unobstructed.

Add materials according to the rated capacity of the equipment. Use appropriate tools. If you need to clear blockages or take samples, be sure to completely shut down and disconnect the power first!

Start the dust removal equipment first, then turn on the screening machine. After the equipment runs smoothly (about 1-2 minutes), slowly pour in the flour to avoid impacting the screen. The basic principle is as follows: Use the vibration motor to excite and drive the screen body to generate high-frequency vibration; the flour is layered on the screen, the fine powder passes through the screen and falls into the discharge port, and large particles or foreign objects are intercepted and discharged; special designs such as anti-blocking devices and ultrasonic systems can improve screening efficiency and accuracy.

Keep an eye on the equipment during operation, listen for abnormal noise, and observe whether there is abnormal vibration, overheating, smoke or dust leakage. If there is any abnormality, shut down the machine immediately and turn off the power for inspection.

The shutdown sequence is to stop feeding first, and then turn off the power of the equipment after the material in the equipment is basically screened and no powder flows out of the discharge port. Avoid starting with material.

Commercial Flour Screening Machine Safe Flour Screening Manufacturer

In terms of flour screening, Dahan Machinery provides a variety of commercial flour sifter for safety sieving flour, which can effectively screen out impurities in flour, ensure the fineness and purity of flour, and meet the needs of commercial production.

Choose the right model: According to your production needs (such as output, flour type, etc.), choose the right Dahan Machinery flour screening machine model. Different models of equipment have different processing capabilities and screening fineness ranges.

Follow the operating manual: Strictly follow the operating manual provided by Dahan Machinery to operate and maintain the equipment. This helps to ensure the safe operation of the equipment and extend the service life of the equipment.

Regular inspection and maintenance: Regularly inspect the screening machine to ensure that the screen is not damaged, the fasteners are firm, and the transmission system is working properly. Replace worn parts in time to avoid production interruptions or safety accidents caused by equipment failure.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Vibrating screen for gypsum processing

The vibrating screen for gypsum processing is a screening equipment used for particle size grading, impurity removal or dehydration of gypsum...

-

What is Banana Sieve

Banana sieve is a new type of screening equipment, named because its screen box is shaped like a banana. Its screen surface is composed of multiple...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.