Spice Sieving Machine

In the process of screening spices (such as pepper, star anise, chili powder, cumin, etc.), the materials often have the characteristics of uneven particles, strong oil content, easy moisture absorption and agglomeration or easy volatility. When choosing a spice sieving machine, you can give priority to equipment with good sealing performance, high screening efficiency, safe materials and easy cleaning. The three-dimensional vibrating screen is a more common spice screening equipment, suitable for the grading and impurity removal of powder, granular and flaky spices. It can replace a variety of mesh screens and supports multi-layer screening, which can complete multi-level sorting at one time.

The main purpose of choosing a spice sieving machine is to solve the problems of low screening efficiency, mixed impurities, easy clogging of the screen, and high material loss during the processing of spices. Therefore, the advantages of a suitable spice sieving machine equipment should fit the usage scenario and actual pain points. The spice sieving machine adopts a multi-layer screen structure, which can achieve multiple functions such as coarse and fine grading, impurity removal, and powder removal. For spices such as chili powder, cumin powder, and star anise that are prone to contain impurities or have different particle sizes, it can effectively screen out unqualified particles and impurities, improve product purity, and ensure uniform discharge.

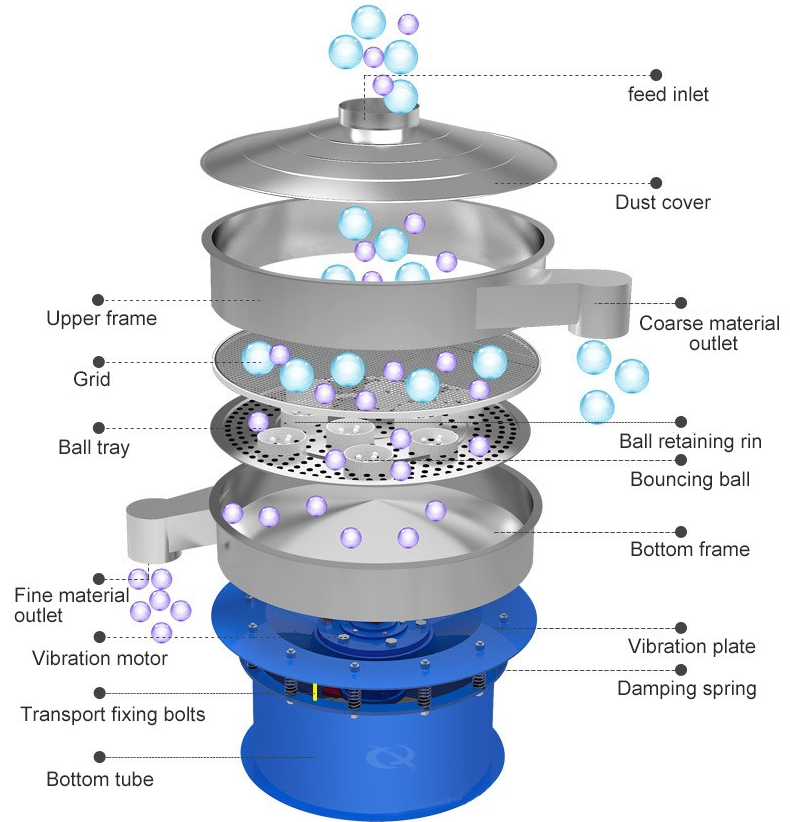

304 or 316L stainless steel materials can effectively avoid spice contamination and odor residue, and ensure food safety. For some spices that are prone to clogging or contain oil, you can also choose a model with an automatic net cleaning device (such as an ultrasonic vibrating screen or a bouncing ball net cleaning structure) to improve the screening rate. In view of the characteristics of spice powders that are easy to absorb moisture and agglomerate, and have strong oiliness, the equipment is usually equipped with a bouncing ball, ultrasonic or rotary vibration screen cleaning system to effectively prevent the screen from being blocked, ensure continuous and stable screening, and avoid frequent shutdowns for cleaning.

Coarse-grained spices (20-40 mesh): mainly used for stewing, pickling, making marinade bags, etc., pursuing visible spice granularity, or for extracting spice flavors and filtering residues. For example: coarsely ground black pepper, peppercorns, star anise, etc.

Conventional spice powder (60-80 mesh): the most common spice powder fineness, widely used in home cooking, barbecue sprinkles, making seasonings, sausage stuffing, etc. For example: curry powder, five-spice powder, chili powder, ginger powder, garlic powder, etc.

Fine-grained spice powder (80-120 mesh): suitable for occasions with high requirements for taste, or where spice powder needs to be quickly dissolved and evenly dispersed. For example: making compound seasoning sauces, baking bread and pastries, adding instant beverages, and certain high-end seasonings, etc.

Ultrafine spice powder (above 150 mesh, even 200-300 mesh): Mainly used in fields with extremely high requirements for product texture and stability, such as medicines, cosmetics, advanced food additives, high-quality flavor and fragrance extraction, etc. The powder is extremely fine, almost without granularity, can achieve the effect of uniform dispersion and no precipitation, and also has unique requirements for the aroma and flavor release of spices. However, it should be noted that overly fine powder is easy to absorb moisture and agglomerate, and screening is more difficult.

Spice screening machines are widely used in many links of spice processing, from preliminary impurity removal, particle size classification, to finished product fine screening, and pre-mixing pretreatment, all play a key role. For example, in the initial processing stage of raw spices such as pepper, star anise, and cumin, many processors think that manual picking is too time-consuming. At this time, it was found that the use of spice screening machines can quickly remove branches, debris, soil and stone debris, greatly saving labor, and the spices after screening are also cleaner, which is convenient for subsequent drying or crushing.

In the production lines of spices such as chili powder, cumin powder, and ginger powder, fine powder is often mixed with unground large particles, which affects the taste and ratio accuracy. After using the spice sieving machine, through 60 mesh, 80 mesh, and 100 mesh classification, large particles and lumps can be effectively screened out to improve product uniformity and stability. Spice companies often encounter the problem of "easy stratification after mixing" when preparing compound seasonings (such as hot pot base and five-spice powder). This is because the particle size of different spice powders varies too much. Using a spice sieving machine to unify the particle size first (such as unifying to 80 mesh) can avoid stratification and improve mixing uniformity and ingredient accuracy.

The core advantage of the spice sieving machine is that it can bring high-efficiency and high-purity screening effects, reduce manual participation, improve hygiene standards, and have good adaptability and ease of operation. It can truly solve common problems such as easy agglomeration, many impurities, and slow screening in the spice production process, and improve overall production quality and efficiency.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Paprika rotary vibrating sieve, seasoning spice sieving machine

Chili powder and chili noodles are undoubtedly a very common condiment in our cooking. Spicy oil, bar ...

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Vibrating screen for gypsum processing

The vibrating screen for gypsum processing is a screening equipment used for particle size grading, impurity removal or dehydration of gypsum...

-

Commercial Flour Sifter for Safety Sieving Flour

Commercial flour sifter for safety sieving flour refers to the process of using professional flour sieving equipment in an industrial pro...

-

Limestone Banana Screen

Limestone is one of the most widely distributed sedimentary rocks on the earth and is widely used in cement production, building stone and...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.