Linear vibrating screen quartz sand

What is Linear Vibrating Screen Quartz Sand?

Linear vibrating screen quartz sand is a commonly used screening equipment in the quartz sand industry. It utilizes a vibrating motor as an excitation source to remove impurities and grade wet or dry quartz sand through coarse or fine screening. The screening particle size range is 0.074mm (200 mesh) to 25mm, and the equipment generally has an output of 0.5 to 20 tons/hour, meeting the needs of quartz sand production lines of varying sizes. The screening efficiency can reach 85% to 95%. For quartz sand materials with uniform particle size and high dryness, the screening accuracy and grading effect are more stable.

Linear vibrating screen quartz sand screen plates are typically made of stainless steel (304/316L) or wear-resistant rubber, ensuring corrosion resistance and durability. The screen box is typically made of Q235 carbon steel and undergoes anti-corrosion treatment. It can remove large impurities, fibers, and other foreign matter while achieving a stable output particle size, facilitating subsequent packaging or further processing.

How does a linear vibrating screen quartz sand screen quartz sand?

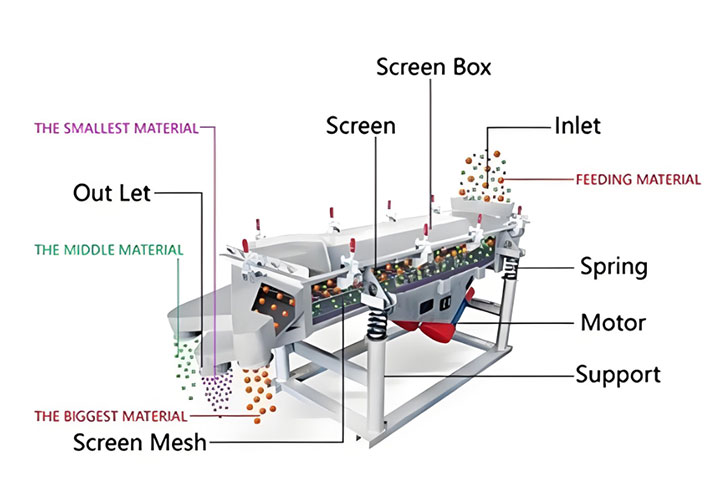

A linear vibrating screen quartz sand uses an eccentric block driven by a motor to generate linear vibration. This vibration forces the quartz sand to move in a parabolic motion along the screen surface, achieving particle size separation. Before screening, select a screen of the appropriate mesh size (10-20 mesh for coarse screens, 100-200 mesh for fine screens), install it in the screen box, and tension it. Quartz sand enters evenly through the feed inlet. During vibration, fine particles (smaller than the screen openings) pass through the screen and fall into the catcher, while coarse particles (larger than the screen openings) move along the inclined screen surface to the discharge end. Adjustable vibration frequency (1500-3000 rpm) and screen angle (3°-8°) improve efficiency. A screen cleaning device (bouncing ball, ultrasonic) prevents clogging and ensures continuous screening.

Linear vibrating screen quartz sand equipment type

Linear vibrating screen quartz sand equipment includes the DZSF-520, DZSF-1020, DZSF-1030, DZSF-1230, and DZSF-1530. For screening ordinary industrial sand, carbon steel Q235 is sufficient. For screening high-purity quartz sand, glass sand, photovoltaic sand, and other materials, 304 or 316L stainless steel fully enclosed structures are available to prevent dust and contamination.

For dry-process quartz sand, standard linear vibrating screens offer high screening efficiency and fast discharge, suitable for particle sizes from 0.074–10mm. These screens are constructed of carbon steel or stainless steel and driven by dual vibrating motors. For wet-process quartz sand, linear vibrating screens with anti-clogging screens are recommended, such as those with an adjustable screen tilt angle (15°-20°) or a bouncing ball screen cleaning device to prevent material adhesion. These screens feature a large screen tilt angle and high water discharge speed. The screen plates are made of polyurethane or stainless steel slats for anti-clogging and corrosion resistance.

Linear vibrating screen quartz sand specifications

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Benefits of Using a Linear Vibrating Screen Quartz Sand

The Linear Vibrating Screen Quartz Sand has many advantages: it evenly distributes screened material, prevents accumulation, and quickly separates quartz sand of varying particle sizes, resulting in high screening efficiency and suitability for large-scale mass production. It can be equipped with multiple layers of screens of varying mesh sizes, simultaneously separating 2-6 particle size grades with precise grading, meeting the refined needs of industries such as photovoltaics, glass, and foundry. Its stable design allows for flexible adjustment of vibration frequency and amplitude based on the moisture content and particle size of the quartz sand, preventing clumping and clogging caused by wet sand. It also resists wear from high-hardness quartz sand, extending equipment life and offering strong adaptability. Furthermore, it offers convenient operation, stable operation, low noise, and simple maintenance and screen replacement, reducing manual intervention, labor costs, and operational complexity.

Linear vibrating screen quartz sand can screen materials of various types.

Linear vibrating screen quartz sand is suitable for dry quartz sand, and can classify coarse, medium, fine and ultra-fine quartz sand into mesh sizes used in building mortar, coatings, ceramic ligands and other fields. It can wet-screen quartz sand with high water content or that needs to be cleaned to remove soil and fine mud. At the end of the production line of water-washed quartz sand or machine-made sand, the water content of the sand can be reduced to the qualified standard for easy transportation and storage. It can also remove impurities such as incompletely crushed ore blocks, wood chips, plastic sheets, etc. mixed in the quartz sand.

Linear vibrating screen quartz sand screening examples

Below are two screening examples using a linear vibrating screen quartz sand. You can select the appropriate model and equipment configuration based on your production output and other requirements.

A small quartz Linear vibrating screen quartz sand selected our company's DZSF-520-2S linear vibrating screen to process 2 tons of quartz sand per hour and screen two grades. This model features a 500mm screen width and two screen layers, capable of separating into two grades: 20-40 mesh and 40-70 mesh. It utilizes standard carbon steel and is equipped with a bouncing ball screen cleaning device to address the high abrasion and clogging characteristics of quartz sand.

A large high-purity quartz Linear vibrating screen quartz sand base selected our company's DZSF-1530-3S linear vibrating screen to meet the core requirements of a high output of 15 tons per hour, screening three grades, and eliminating iron contamination. A 1500mm screen width ensures maximum processing capacity, and the three-layer screen design accurately separates into three grades: 30-50 mesh, 50-100 mesh, and 100 mesh and above. Parts of the equipment that come into contact with the material are constructed of 304 stainless steel. A powerful bouncing ball screen cleaning device is also included. The high proportion of fine powder (e.g., above 100 mesh) screened is achieved through the addition of an ultrasonic screen cleaning system, eliminating screen clogging and enabling continuous production.

Linear Vibrating Screen Quartz Sand Manufacturer

Our factory boasts significant advantages in the production of linear vibrating screen quartz sand. With 18 years of experience in the vibration equipment field, we provide comprehensive customer service, from equipment R&D and manufacturing to after-sales support. We produce a variety of models, from the DZSF-512 to the DZSF-1854, to meet the needs of quartz sand screening, from coarse to fine. We can also customize the equipment with sandblasting and leg heightening options based on the material's characteristics.

Display of Different Linear Vibrating Screen Quartz Sand Models

-

Double deck vibrating screen has two layers of screens installed inside.

-

Battery Anode Materials Vibrating Sieve

The separation accuracy is allowed to be as low as 20µm (#635 mesh), the sieving accuracy can be increased by 1-70% ...

Related news-

Standard test sieve price

Standard test sieve price usually ranges from US$20 to US$300, depending on the size, material and accuracy level...

-

Vibro Sifter Flour

The Vibro Sifter Flour uses a motor-driven eccentric weight to generate three-dimensional vibration...

-

Vibro Sifter Baking Soda

Vibro Sifter Baking Soda is a process or equipment that uses a vibrating screen to sieve, grade, or filter baking soda...

-

Linear Vibrating Screen For Plastic Particles

Linear Vibrating Screen For Plastic Particles is used for screening and grading plastic particles...

-

High -frequency vibration sieve for latex paint filter

High -frequency vibration sieve for latex paint filter is a filtration device designed for high-viscosity liquid systems such as water-based paints ...

-

Vibro Sifter Magnesium Oxide

Vibro Sifter Magnesium Oxide refers to the process of using a vibro sifter to grade and screen magnesium oxide powder...

-

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.

-

Reach Us

Xinxiang Dahan Vibration Machinery Co., Ltd.

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.

-

WhatsApp:+86 15236742901 E-mail:sale@xxdahan.com