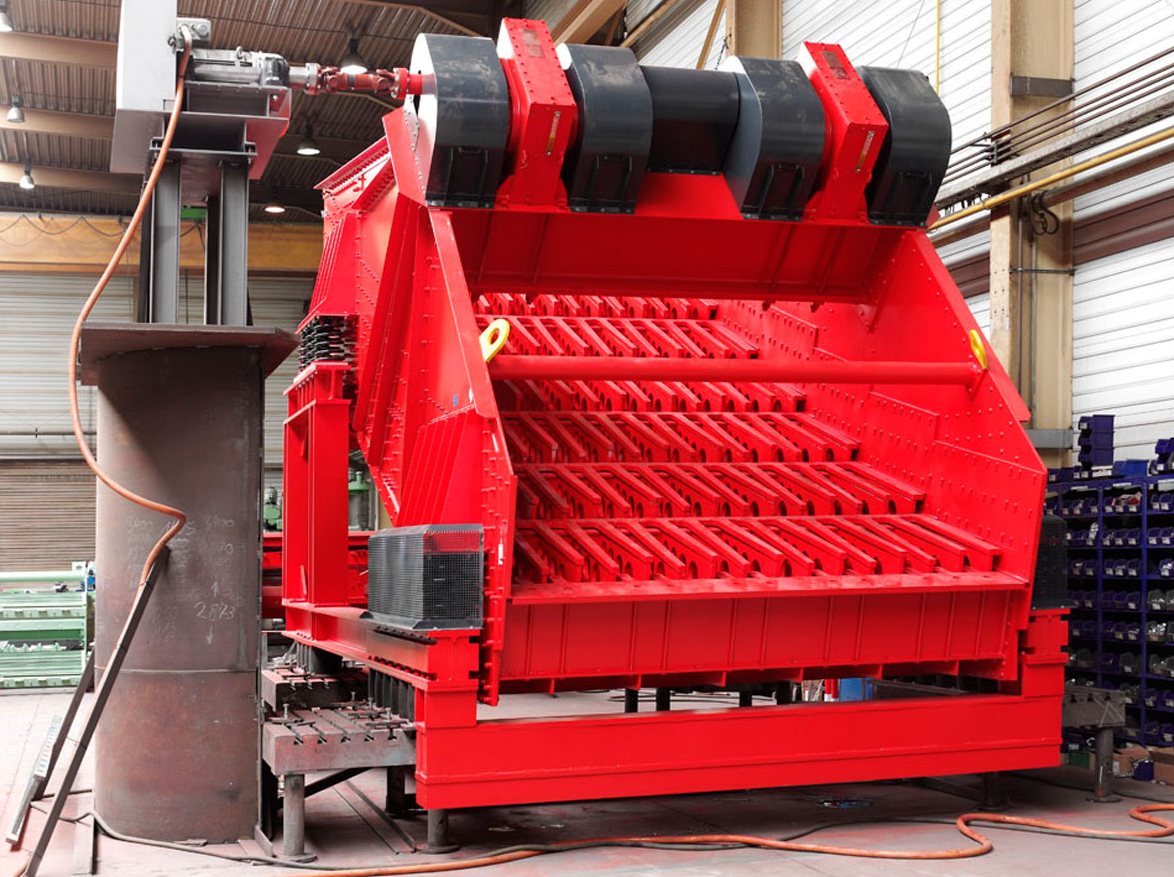

Limestone Banana Screen

Limestone is one of the most widely distributed sedimentary rocks on the earth and is widely used in cement production, building stone and metallurgical industry. In the mining and processing of limestone, the limestone banana screen is used for screening limestone and other medium-hardness materials with its inclined design and unique conveying capacity. The banana screen is used for screening limestone mainly because its unique multi-angle screen surface design brings significant efficiency and precision advantages, which is particularly suitable for processing large amounts of limestone materials with a wide range of particle sizes.

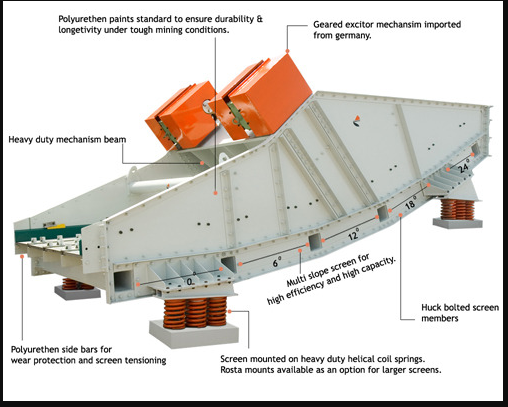

The core structure of the limestone banana screen includes screen box, screen mesh, vibration motor and support structure. Its screen surface is composed of multiple sections of screen bars with different inclinations, and the overall shape is banana-shaped (usually steeper and the rear section is gentler). This design enables limestone to be graded and screened on the screen surface.

Screen material: High wear-resistant manganese steel is usually used to deal with the hardness of limestone

Vibration system: Dual vibration motors are synchronously excited to ensure consistent linear motion

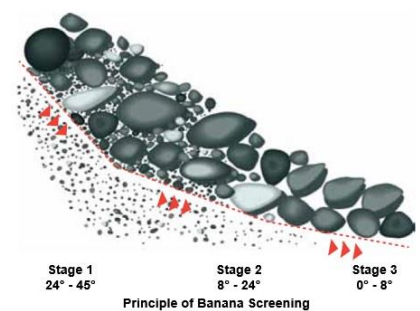

Based on vibration screening technology, the screen surface of the banana vibrating screen is designed with multiple ends with different inclination angles. The inclination angle at the feed end is large, which is convenient for rapid dispersion of materials; the inclination angle in the middle section gradually decreases to make the materials evenly distributed; the inclination angle at the discharge end is the smallest, which is convenient for screening. Limestone enters from the front end of the screen box (steep slope section). Due to the large inclination angle and vibration, large pieces of limestone materials pass quickly, reducing the risk of blockage; after entering the second half (gentle slope section), fine particles achieve accurate classification and relatively fine screening at a lower inclination angle and vibration. This segmented form greatly improves the production efficiency and production capacity of limestone.

Limestone mesh recommendation

Limestone in cement production is mainly used as the main raw material, and generally needs to be crushed to a finer particle size for subsequent grinding.

Coarse/medium crushing stage: Usually used for crushed aggregates, the mesh size range may be from a few millimeters to tens of millimeters (for example, the particle size is controlled at 20-40 mm, or smaller after screening).

Grinding stage: Limestone will be ground into fine powder together with clinker. At this time, the particle size is very fine, usually measured in microns, and the corresponding mesh size will be very high, such as above 200 mesh, even up to 325 mesh or even higher, to ensure full mixing with clinker and meet the fineness requirements of cement.

As a construction aggregate (such as crushed stone, sand substitute), the mesh size range of limestone will be wider, depending on the specific use, such as concrete aggregate, roadbed material, etc.

Coarse aggregate: The particle size is larger, usually above 5 mm, and the corresponding mesh size is lower (for example, less than 4 mesh).

Fine aggregate: The particle size is smaller, usually between 0.075 mm and 5 mm, and the corresponding mesh size is between 200 mesh and 4 mesh.

Stone powder (in machine-made sand): Sometimes it is required to contain a certain amount of stone powder (less than 0.075 mm), and the corresponding mesh number will be very high.

The relevant technical indicators of limestone include:

Processing capacity: 50-800 tons/hour

Screening particle size: 0.5-150mm

Vibration frequency: 700-1000 times/minute

Double amplitude: 2*5.5-2*30KW

Power: 4-8mm

In actual application, limestone banana screen is suitable for a variety of working conditions; pre-screening and inspection screening of limestone crushing system; particle size classification of limestone orthopedic production; raw material screening of limestone grinding system; particle size control of desulfurized limestone. In the cement industry, limestone banana screen can perform the initial classification of limestone raw materials, screening out limestone particles and other impurities that do not meet the requirements; in the metallurgical industry, it is used for particle size control of limestone solvents; in the chemical industry, it can also be used for fine classification of limestone powder; in related construction industries, banana screens can be used for particle size separation in aggregate production.

The purpose of choosing banana screen to screen limestone is to maximize production efficiency and processing capacity while ensuring screening accuracy, while reducing blockage and equipment wear, thereby reducing production costs. Whether it is pre-screening before crushing, or particle size classification after crushing, or even processing water-containing limestone in wet screening, it can show good performance.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Vibrating screen for gypsum processing

The vibrating screen for gypsum processing is a screening equipment used for particle size grading, impurity removal or dehydration of gypsum...

-

Commercial Flour Sifter for Safety Sieving Flour

Commercial flour sifter for safety sieving flour refers to the process of using professional flour sieving equipment in an industrial pro...

-

Tumbler Screen Solid-Liquid

A sewage treatment customer needs to perform preliminary solid-liquid separation on aquaculture wastewater. The daily processing volume is la...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.