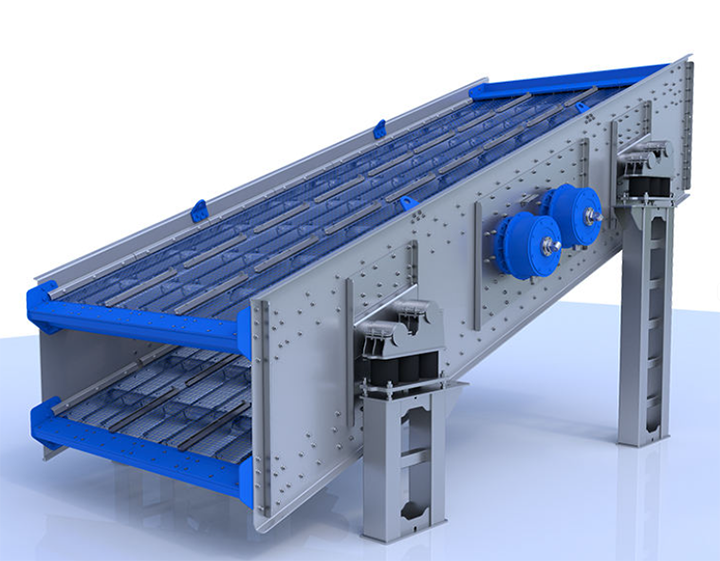

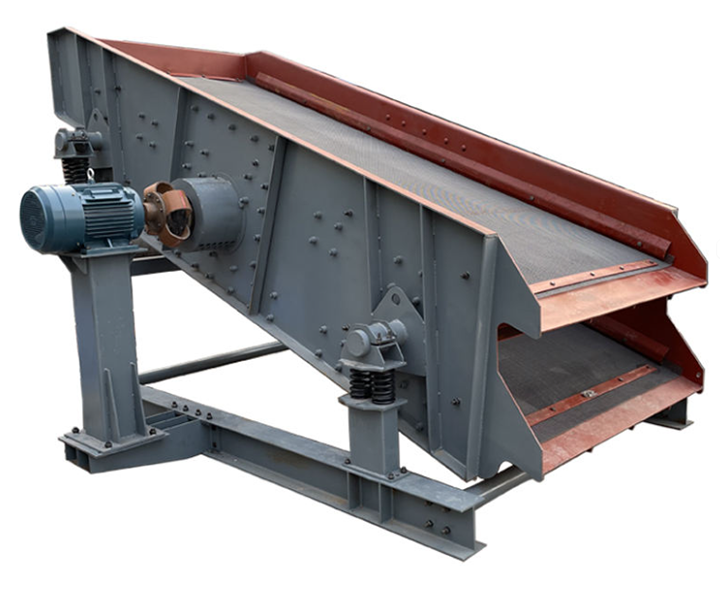

Limestone double deck with incline vibrating screen

Limestone double deck with incline vibrating screen utilizes reciprocating vibration provided by an exciter motor or eccentric shaft to cause the material to move forward in a continuous, jumping motion along the inclined screen surface. The inclination angle typically ranges from 15° to 25°. Under common operating conditions, this equipment achieves a screening efficiency of 85–95% and a screening accuracy of 80–90%.

The processing capacity ranges from 80–500 t/h, typically producing 2–3 grades of finished material, such as combinations of 0–5 mm, 5–20 mm, and 20–40 mm. Screen sizes are configured according to particle size requirements, such as an upper layer with 20–40 mm square holes and a lower layer with 5–20 mm square holes or woven mesh, to ensure appropriate gradation and throughput. The final product particle size range typically covers 0–40 mm or larger, meeting the needs of closed-loop crusher operation or finished aggregate production.

Limestone Double Deck with Incline Vibrating Screen Screening Process

The Limestone double deck with incline vibrating screen has two identical vibrating motors symmetrically mounted on both sides of the screen box. They rotate synchronously in opposite directions. Their centrifugal forces cancel each other out in the direction parallel to the motor axis, and combine into a powerful excitation force in the direction perpendicular to the axis, forcing the entire screen body to vibrate in an approximately circular motion. This motion trajectory effectively throws the material up and conveys it forward, while creating optimal conditions for fine particles to pass through the screen.

Feeding and Primary Screening: Limestone raw material is fed into the feed box at the top of the vibrating screen by a feeder and dispersed across the entire width of the upper screen. Under the intense vibration of the upper screen, material smaller than the upper screen aperture size quickly passes through the screen and falls into the lower screen; while coarse material larger than the screen aperture is bounced up and moves along the inclined angle of the screen surface towards the coarse material discharge port at the front of the equipment.

Secondary Screening and Product Separation: The material falling into the lower screen continues to undergo secondary screening. Ultrafine materials smaller than the lower screen apertures pass through the screen and fall, exiting from the bottom fine material outlet. Medium-sized materials, falling between the apertures of the upper and lower screens, move along the lower screen surface and exit from the middle outlet.

The entire process: Throughout the process, material flow relies entirely on vibration and gravity, requiring no additional power. The path is clear, and there is no cross-contamination, ensuring high precision and efficiency in screening.

What are the advantages of the Limestone double deck with incline vibrating screen?

The Limestone double deck with incline vibrating screen can handle mixtures containing a large amount of stone powder produced after limestone crushing. Strong vibration effectively prevents wet fine powder from clogging the screen, ensuring that even fine powder can be separated. The following are the advantages of this equipment in screening limestone.

The advantage of the double-layer design of the Limestone double deck with incline vibrating screen is that it allows for multi-stage grading within a single unit. A single processing step can precisely separate raw materials into coarse, medium, and fine grades, simplifying the process and saving on equipment investment and floor space.

The inclined installation of the screen box provides the material with automatic forward propulsion. The combination of the inclination angle and vibration direction ensures sufficient residence time for screening while ensuring continuous movement towards the discharge end, preventing material accumulation. This is suitable for processing loose materials with relatively good flowability, such as limestone.

The screen mesh is made of high-manganese steel or wear-resistant alloy steel, possessing extremely high wear resistance and effectively resisting the abrasion of limestone. The screen box side plates are typically welded from high-strength steel plates, resulting in a robust and durable structure.

The motor uses a high-efficiency, durable vibratory motor as the excitation source. These motors typically have a high IP66 protection rating, are dustproof and waterproof, and are suitable for harsh mining environments. Furthermore, the eccentric design of the motor blocks allows for stepless adjustment of the excitation force by adjusting the angle of the eccentric blocks, thus flexibly controlling the throwing intensity and screening speed of the material to adapt to limestone raw materials with different moisture content and particle sizes.

Application Example of Limestone Double Deck with Incline Vibrating Screen

An aggregate production line utilizes a Limestone double deck with incline vibrating screen. After two stages of crushing by a jaw crusher and an impact crusher, the mixture is conveyed to this double-layer inclined vibrating screen. By configuring a 40mm upper screen and a 12mm lower screen, the material is successfully separated into: >40mm aggregate is returned to the crusher for further crushing; 12-40mm high-quality aggregate is directly used in commercial concrete mixing plants; and 0-12mm fine material is partially sold as stone chips and partially sent to a sand making machine for further shaping. This demonstrates that the equipment can ensure products meet construction requirements and improve resource utilization.

The Limestone double deck with incline vibrating screen, through its double-layer screen surface, reasonable inclination angle design, and stable vibration force, can achieve dispersion, stratification, and screening of limestone materials, meeting the requirements of large throughput, multi-specification grading, and high precision. Its robust structure is suitable for continuous screening operations of hard limestone. It plays an important role in large-scale limestone quarries, aggregate production lines, and limestone powdering systems.

-

Liquid vibratory sifter is a device used to separate solid particles from liquid.

-

Raw sesame is often mixed with soil, sand, metal chips, glass fragments, etc. These impurities not only affect the taste.

-

Carbon steel vibrating screen is a device that uses the principle of vibration to screen granular or powdered materials.

-

Double deck vibrating screen has two layers of screens installed inside.

-

Charcoal powder grading vibrating screen

Charcoal powder grading vibrating screen is a high-performance device used to classify charcoal powder by particle size...

-

Tumbler Screening Machines

Tumbler Screening Machines are available in carbon steel, stainless steel, and special steel to meet...

-

Electric Automatic Sieve Shaker Vibrating Sieve Machine

Electric Automatic Sieve Shaker Vibrating Sieve Machine are commonly used in laboratories and industrial production...

-

Charcoal Sieving Carbon Steel Round Vibrating Screen

Charcoal Sieving Carbon Steel Round Vibrating Screen enables rapid grading and impurity removal from flake, strip, and powdered charcoal...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.