Chinese medicine particle swing screen

What is Chinese medicine particle swing screen?

Chinese medicine particle swing screen is the main equipment in the production of Chinese medicine preparations, designed for particle classification, impurity removal and particle size control. The commonly used screen mesh range is 20-200 mesh. The coarse screen (20-60 mesh) is used for the preliminary screening of raw materials and the separation of impurities; the medium screen (60-120 mesh) completes the particle classification; the fine screen (120-200 mesh) is used to prepare ultrafine powders or high-precision preparations. The output of this equipment reaches 50-2000 kg/hour, which is 5-10 times that of ordinary vibrating screens, and the screening accuracy is as high as 90%-95%, which is especially suitable for the processing of Chinese medicine particles that are easy to block the net and have irregular shapes.

Common models of Chinese medicine particle swing screen include YBS-600, YBS-800, YBS-1000, YBS-1200, YBS-1500, YBS-1600, etc. The number of layers is usually 1-5, which can be customized according to the particle classification requirements. For example, a 3-layer sieve can separate coarse, medium and fine particle sizes at the same time, and a 5-layer sieve can complete multiple levels of classification at one time. Increasing the number of layers can improve the classification accuracy and meet the screening needs of multi-specification Chinese medicine particles.

Chinese medicine particle swing screen

What is the working principle of the Chinese medicine particle swing screen?

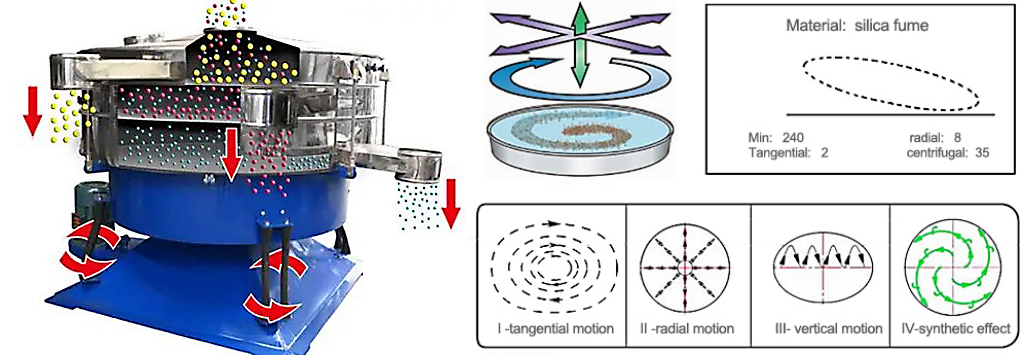

Chinese medicine particle swing screen adopts the screening principle of artificial swinging. The eccentric mechanism is driven by a motor to make the screen body produce a three-dimensional elliptical motion trajectory. The material spreads in a spiral shape on the screen surface, and is quickly layered and screened under the gentle swinging action. Fine particles are separated through the screen, and coarse particles are discharged along the inclined screen surface. Its low speed and large swing amplitude design can effectively reduce material breakage and screen blockage, and is especially suitable for fine grading of fragile materials such as Chinese medicine particles. The screening efficiency can reach more than 95%.

The structure of Chinese medicine particle swing screen

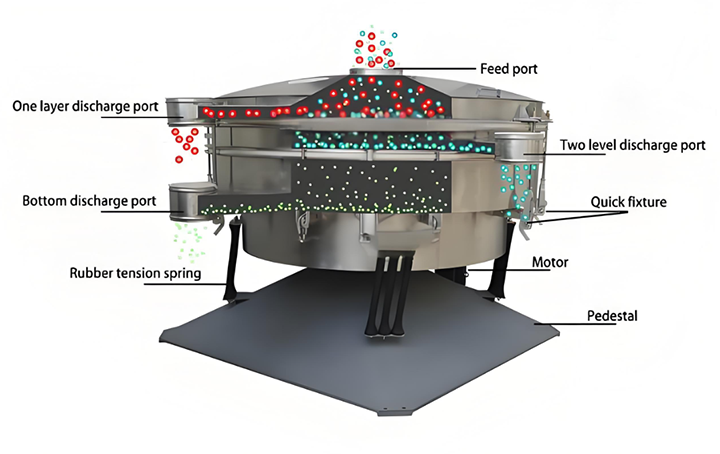

Chinese medicine particle swing screen consists of a screen box, screen mesh, drive device, support device, inlet and outlet, and other components. The screen box is equipped with multiple layers of screen mesh with different apertures to accurately separate Chinese medicine particles of different particle sizes; the drive device uses an explosion-proof motor with an eccentric mechanism to safely drive the screen box to produce a swinging motion to ensure a stable screening effect; the support device provides a stable support for the overall structure and transmits power. The feed port is reasonably designed to ensure uniform distribution of materials, and a variety of outlet configurations (such as side discharge, bottom discharge or segmented discharge) can flexibly adapt to different process requirements to achieve rapid classification and collection of multi-level particles.

Chinese medicine particle swing screen selection

When screening Chinese medicine particles, the Chinese medicine particle swing screen should be made of stainless steel. It is resistant to acid, alkali, and salt corrosion, which will not damage the important drug particles. The equipment is wear-resistant and has a long service life. Carbon steel is prone to rust and may cause changes in drug composition.

What are the advantages of the Chinese medicine particle swing screen?

Chinese medicine particle swing screen has outstanding advantages: it can solve the problem of high fine powder content and difficult separation; it can accurately classify particles of different particle sizes; it can avoid clogging due to irregular particle shapes; it can also deal with the stickiness or hygroscopicity of Chinese medicine particles. The detailed advantages are as follows:

Solve the problem of high fine powder content and difficulty in complete separation: the swing screen simulates manual screening, and the material makes a low-speed circular, elliptical or linear reciprocating motion on the screen surface. This mode of movement allows the fine powder to have more time to pass through the screen and fully separate from the larger particles, avoiding the situation where the fine powder is quickly taken away from the screen surface and cannot be effectively separated. The separation effect of fine powder can also be optimized by adjusting the swing amplitude, frequency and inclination angle of the screen.

Accurately classify particles of different sizes: Chinese medicine particle swing screen can usually be equipped with multiple layers of screens with different apertures to achieve one-time classification of materials into multiple particle size ranges. Its characteristics of simulating manual screening ensure that the material has enough residence time on each layer of the screen for classification, thereby obtaining a more accurate particle size distribution. By selecting the appropriate screen specifications and combinations, different particle size classification requirements can be met.

Dealing with irregular particle shapes, leading to blockage problems: The motion trajectory of the swing screen has a gentle rolling and throwing action, which helps irregularly shaped particles adjust their posture on the screen surface, reducing the chance of their sharp or irregular parts being directly perpendicular to the mesh, thereby reducing the risk of blockage.

Dealing with the problem of stickiness or hygroscopicity of Chinese medicine particles: Although the low-speed motion of theChinese medicine particle swing screen is relatively gentle, its unique motion trajectory can still provide a certain shear force and dispersion effect, which helps slightly agglomerated particles to disperse on the screen surface and increase their chances of passing through the screen. The adhesion of the material can be reduced by selecting a screen material and surface treatment process with self-cleaning function.

The difference between vibrating screen and Chinese medicine particle swing screen

|

Features |

swing screen |

vibrating screen |

|

Working principle |

low-frequency swing motion, simulating artificial shaking, the material moves in an elliptical or straight trajectory |

high-frequency vibration, the material quickly jumps and moves on the screen through vibration |

|

Movement mode |

plane swing, gentle, the action is similar to manual screening |

up and down or multi-directional vibration, the action is violent |

|

Suitable materials |

frac160,000, sticky or wet materials, such as Chinese medicine particles, concentrated particles |

ordinary powder, particles, suitable for hard or non-breakable materials |

|

Screening accuracy |

high, suitable for multi-level classification, uniform particle size distribution |

general, suitable for rough screening or mass production |

|

Material damage |

low, protect the integrity of Chinese medicine particles |

high, may cause particle breakage or pulverization |

|

Output |

low (0.5-10 tons/hour, depending on the model) |

high (up to 20 tons/hour or more, depending on the model) |

|

Applicable scenarios |

classification of Chinese medicine particles , impurity removal, shaping after granulation, fine screening of food and chemical industry |

large-scale industrial screening, such as chemical industry, mining industry, and food rough processing |

Common technical parameters of Chinese medicine particle swing screen

| Particle feed size: | 1 micron up to 20 mm | ||||||

| Feed rates: | 1kg/h – 50 ton/h | ||||||

| Bulk densities: | 20 – 10000 grams/liter | ||||||

| Mesh openings: | 20 microns to 20 mm | ||||||

| Screens usable: | 304, 316L, or 430 stainless steels or plastic wire mesh fabric, perforated plates | ||||||

| No. of screen decks: | 1 – 6 per machine | ||||||

| Anti-blinding systems: | – Rubber balls | ||||||

| – Rotating roller brush arms | |||||||

| – Rotating air-jet nozzle arms | |||||||

| – Ultrasonic | |||||||

| – Combinations | |||||||

| Speed range: | 180-280 min-1 | ||||||

| Screen movement: | Three-dimensional, set to product | ||||||

| Amplitude: | 40-80 mm horizontally and 5-40 mm vertically | ||||||

| Acceleration: | 1,3-1,8 g | ||||||

| Model sizes/ca. Ø: | 600 | 1000 | 1200 | 1600 | 2000 | 2400 | 2600 |

| Screening surface (m²): | 0.292 | 0.785 | 1.13 | 1.83 | 2.63 | 4.52 | 5.31 |

| Motor power (kW): | 0.25 | 1.5 | 2.2 | 2.2 | 4 | 5.5 | 5.5/7.5 |

| Materials: | Carbon steel, Stainless and Special steels | ||||||

| Surfaces: | Painted, brushed or ground, mirror or electro polished, and ViwateQ options for Food and Pharmaceutical products with a surface roughness of < 0.4 microns (GMP, FDA compliant). | ||||||

Application of Chinese medicine particle swing screen

Chinese medicine particle swing screen is used in the production of traditional Chinese medicine for particle classification, powder screening, pill sorting and impurity removal. It can effectively screen out impurities, ensure the purity of medicinal materials, improve product quality and production efficiency, and ensure that the medicine meets the quality standards.

Chinese medicine particle production: In the production process of Chinese medicine particles, it is used to grade and screen the prepared Chinese medicine particles, remove oversized or undersized particles, ensure the uniformity of the particle size of the product, and improve the product quality.

Chinese medicine powder screening: It can be used for screening Chinese medicine powder, grading Chinese medicine powder according to different fineness requirements, and providing qualified raw materials for subsequent preparation processes.

Chinese medicine pill screening: For the production of Chinese medicine pills, the Chinese medicine particle swing screen can be used to screen out pills of uniform size, remove unqualified pills, and ensure the quality and specification consistency of the pills.

Chinese medicine particle swing screen is an efficient screening equipment widely used in the Chinese medicine industry. The equipment is equipped with multiple screen layers, which can perform multi-stage screening to ensure the accuracy of particle separation. The overall design is compact and suitable for use by small and medium-sized enterprises on production lines. The Chinese medicine particle swing screen not only improves production efficiency, but also provides strong support for the modernization of the Chinese medicine industry.

-

Granules, powders, and paddle materials can be used.

-

Meet the needs of large-scale and high-precision screening

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Pharmaceutical excipient powder vibrating screen

Pharmaceutical excipient powder vibrating screen is a screening device designed to meet the special physical and chemical properties of...

-

TPU Polymer Powder Sieving Machine

TPU polymer powder sieving machine is a mechanical equipment specially used for particle size classification, impurity removal or particle...

-

Tea seed grading linear vibrating screen

The tea seed grading linear vibrating screen is a key equipment used in the tea processing field for screening and grading tea seeds. Its core function is to achieve...

-

Circular swing screen

Circular swing screen, also known as swing screen or shaking screen, is a low-frequency rotary vibration screening equipment that imitates manual shaking screening...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.