Vibrating Springs For Powder Sieves

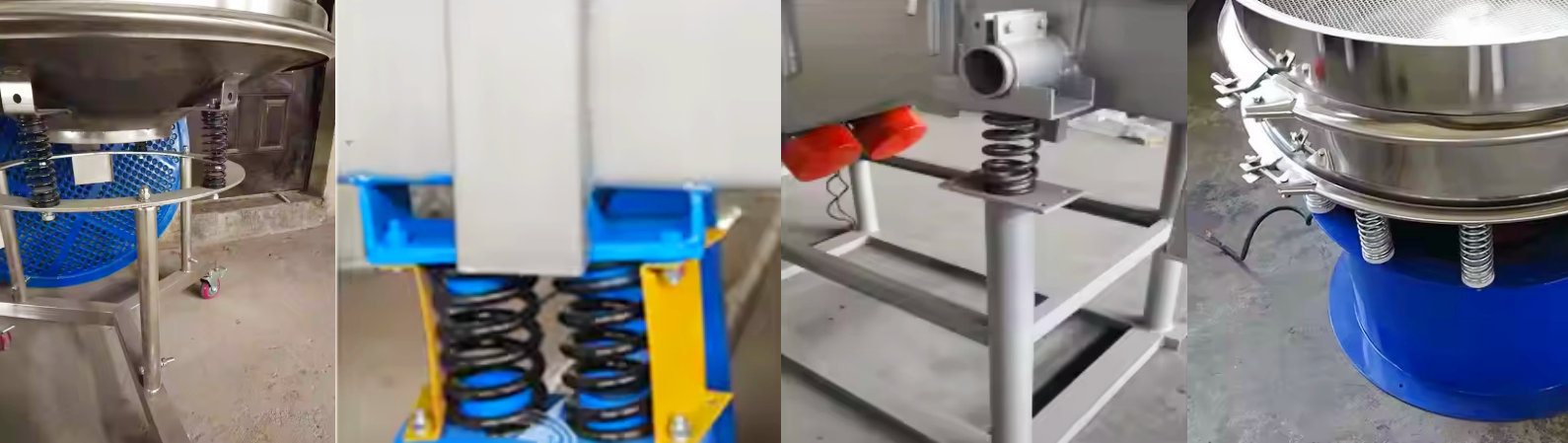

Vibrating springs for powder sieve is a key elastic element used in powder screening equipment. It is usually installed between the screen body and the base. Its main function is to provide elasticity and vibration reduction for the vibrating screen, so that it can stably and efficiently complete the screening of materials, ensure smooth screening of materials and protect the equipment at the same time.

What is the main function of the vibrating springs for powder sieve?

The vibrating springs for powder sieve is an important component used in powder screening equipment for shock absorption, support and vibration adjustment. It is mainly used for shock absorption, buffering and supporting the screen body to ensure the stable operation and efficient screening of the vibrating screen.

Shock absorption and buffering: The spring is located between the screen box and the support base, which plays a role of buffering and shock absorption. It can effectively absorb the impact force generated during the vibration process, prevent excessive excitation force from causing damage to the screen box itself (such as cracking and deformation), and also reduce the transmission of vibration to the equipment foundation and the surrounding environment.

Supporting function: Supporting the screen box and other components of the powder screen to ensure that the screen box maintains a stable position and posture during the vibration process, so that the screening work can proceed normally.

Adjusting vibration: The spring transmits the excitation force generated by the vibration motor to the screen box, so that the screen box vibrates regularly. By selecting springs with different stiffness and damping characteristics, the vibration frequency, amplitude and other parameters of the powder screen can be adjusted to meet the screening needs of different materials and improve the screening efficiency and accuracy.

Types of vibration springs

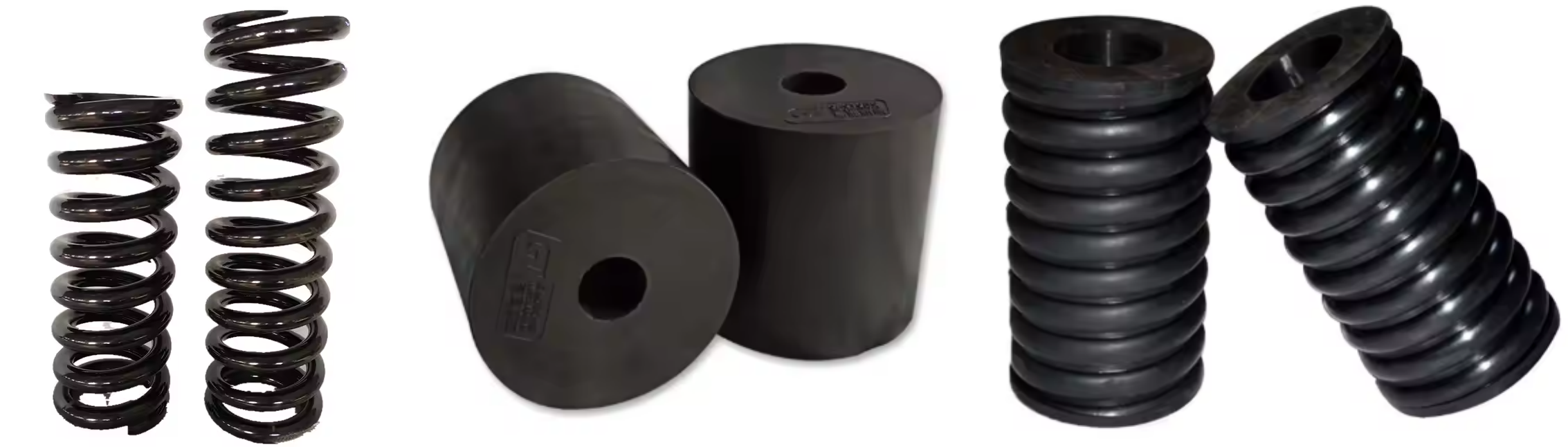

Wire compression spring: This spring is wound by spring steel wire and is mainly used to withstand axial pressure. It has a simple structure, low manufacturing cost and is easy to install, and is widely used in various mechanical equipment. The characteristics of the wire compression spring are that it can provide greater elasticity and longer service life.

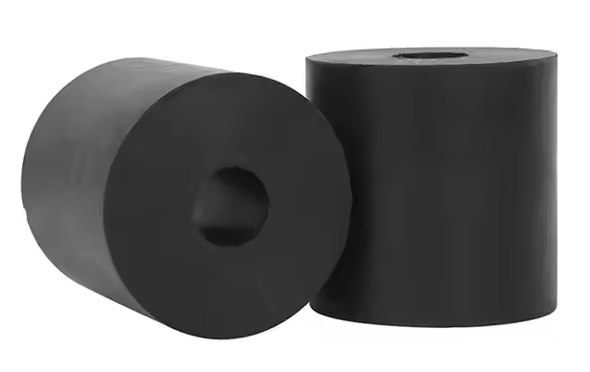

Rubber spring: Made of natural rubber or synthetic rubber, it has good elasticity and vibration reduction performance. Compared with metal springs, rubber springs are better at absorbing shocks and reducing noise. In addition, it has a certain degree of corrosion resistance and is suitable for some chemical environments.

Composite springs: Composite springs combine the advantages of metal and rubber, usually wrapping a layer of rubber around the metal spring or combining the two in other ways. This design allows the composite spring to have both the good elasticity and load-bearing capacity of metal springs and the excellent vibration reduction and sound insulation effects of rubber springs. Therefore, composite springs are particularly suitable for use in industrial fields with higher requirements, such as medium and high frequency precision screens, fine vibrating screens, etc.

Classification comparison table of vibrating springs for powder sieves

|

Spring type |

Image |

Construction material |

Features |

Scope of application |

|

Wire compression spring |

|

Spring steel wire (such as 65Mn) |

Simple structure, low price, strong bearing capacity, moderate service life |

Commonly used in ordinary vibration screens and heavy equipment |

|

Rubber spring |

|

Natural rubber or synthetic rubber |

Good vibration reduction effect, low noise, corrosion resistance, large deformation |

Suitable for powder screens, food screens, experimental screens, etc. |

|

Composite spring |

|

Rubber + metal frame |

Integrates rigidity and flexibility, taking into account both bearing capacity and shock absorption performance |

Mostly used in medium and high frequency precision screens and fine vibration screens etc. |

Application scenarios of common spring types in powder vibrating screens

Wire compression springs are commonly used in ordinary three-dimensional rotary vibrating screens and linear vibrating screens. They have strong bearing capacity and low cost, and are suitable for heavy loads or medium-frequency vibrations. They are commonly used when screening heavy materials such as metal powders and mineral powders. Rubber springs are often used in powder screening conditions that require high noise control and soft vibration, such as ultrasonic vibrating screens used in the chemical, food, and pharmaceutical industries. Composite springs are used in fine screening equipment that requires high shock absorption and support force, and are suitable for high-frequency screens or high-precision powder screens, such as carbon powder, graphite powder, and other precision screening.

How to choose a suitable vibrating springs for powder sieve

Choosing a suitable vibrating springs for powder sieve is the key to ensuring efficient and stable operation of the equipment. The following factors need to be considered comprehensively:

First, the load requirements. The spring must be able to withstand the static and dynamic total weight of the screen box and the material. The second is the material properties, such as density, corrosiveness, and temperature, which will affect the material selection and performance of the spring. The next is the screening purpose and accuracy requirements. If there are high requirements for noise control and vibration isolation, then rubber springs or composite springs with better shock absorption will be a better choice. Finally, don't forget to consider the equipment operating parameters, including vibration frequency, amplitude and installation space, to ensure that the natural frequency of the spring matches the screen machine and meets the installation dimensions.

When making the actual selection, it is recommended that you:

Understand the parameters of your powder screening equipment and the characteristics of the material to be screened in detail.

Consult a professional vibrating screen manufacturer or spring supplier. They can provide professional advice and customized solutions based on your specific needs.

Consider the long-term operating cost. Although some spring types may have a higher initial cost, their longer service life and lower maintenance frequency may bring better overall economic benefits.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Vibrating screen for gypsum processing

The vibrating screen for gypsum processing is a screening equipment used for particle size grading, impurity removal or dehydration of gypsum...

-

Centrifugal Sifter For Green Tea Sieving

Centrifugal sifter for green tea sieving Company has launched a new centrifugal sifter for green tea sieving , which aims to provide efficient...

-

Machine For Sieving Flour With

Machine for sieving flour with a device is specially used for grading and sieving flour. Its core advantage is that it can accurately control the...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.