Machine For Sieving Flour With

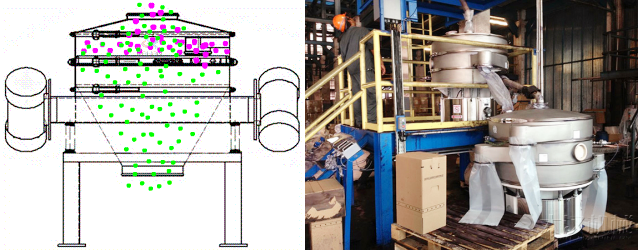

Machine for sieving flour with a device is specially used for grading and sieving flour. Its core advantage is that it can accurately control the particle size distribution of flour particles. Flour, as a fine powder material, has complex characteristics, contains impurities such as bran and germ, and the particles are of different sizes and are easy to agglomerate or adhere. Traditional sieving equipment may cause sieve hole blockage or flour overheating. In contrast, the flour sieving machine uses multi-layer sieves (the mesh range is usually 40-120 mesh, about 0.1-0.4 mm), and uses controllable high-frequency vibration to quickly disperse flour, fine particles pass through the sieve, and coarse impurities are separated, significantly improving sieving efficiency and flour purity.

What is the main function of a flour sieving machine?

There are many types of flour sieving machines. After the initial grinding of coarse flour or semi-finished flour, a linear vibrating screen or a rotary screen is used to separate large particles of unground bran from finer flour to prevent impurities from entering the next process.

After the flour is basically ground and formed, the flour is graded according to the mesh size (such as 60 mesh, 80 mesh, 100 mesh, etc.) through a rotary vibrating screen or an ultrasonic vibrating screen. Ordinary wheat flour is usually sieved to about 80 mesh; high-precision cake flour and pastry flour require more than 100 mesh; special flour (such as refined flour) requires further use of ultrasonic vibrating screens to achieve high-precision screening.

The magnetic device and ultrasonic device in the screening equipment can effectively remove metal impurities and black spots, and improve the purity and sensory quality of flour. Some of the coarse particles that are screened out can be sent back to the milling system for re-grinding, and the utilization rate of wheat can be improved through closed-loop screening.

How does the special straight-discharge flour sieving machine improve the accuracy of flour?

Multi-dimensional vibration: The upper and lower eccentric blocks on the motor shaft convert the rotational motion into multi-dimensional forces of horizontal, vertical, inclined and centrifugal action. This multi-dimensional force causes the flour to make complex movements on the screen surface, and the particles collide and disperse with each other, which helps small particles pass through the screen and large particles are screened out, thereby improving the screening accuracy.

Automatic discharge: The dual-vibration source direct discharge screen causes the material to produce vortex motion on the screen surface and has an automatic discharge function. This automatic discharge method avoids the accumulation and blockage of materials on the screen surface, ensures the continuity and stability of the screening process, and further improves the screening efficiency and accuracy.

Recommended mesh size of machine for sieving flour with

The selection of mesh size of machine for sieving flour with mainly depends on the purpose of flour and the required fineness grade. The general recommendation is as follows:

Ordinary flour is usually sieved between 60 mesh and 80 mesh, which is suitable for daily baking and pasta processing. The particles are relatively uniform and not too fine; high-end cake flour and pastry flour are recommended to use 80 mesh to 100 mesh sieves to ensure that the flour is fine and soft, suitable for fine baking requirements

Special refined flour (such as infant formula powder, medical powder) usually uses 100 mesh or more or even 120 mesh to ensure extremely fine powder, no impurities and agglomeration; ultrafine flour may use ultrasonic vibration screens above 150 mesh to assist screening, improve the pass rate and prevent clogging.

Application of machine for sieving flour with

Machine for sieving flour with is widely used in flour production, mainly used to remove impurities, grade particles and improve flour precision to meet different food processing needs. In large flour mills, flat rotary screens or straight-row screens are used for the initial screening of ground materials. They are equipped with a 0.3 mm screen and can process 5 tons of materials per hour, removing 98% of impurities such as bran and stones to ensure that the flour purity meets the standard (such as ash content below 0.55%).

In the scenario of producing low-gluten cake flour, the straight-row flour screener uses a 0.1 mm screen for fine screening, and 90% of the particles are less than 0.15 mm, which improves the fineness and baking performance of the flour. Small flour mills often use single-layer vibrating screens to screen general-purpose flour, processing 1-2 tons per hour to remove coarse particles to meet the flour needs of noodles or steamed buns. In addition, the screener uses an automatic screen cleaning device (such as ultrasound) to prevent blockage, maintain screening efficiency, and protect downstream equipment. Whether it is a large production line or a small processing, the flour screener ensures stable product quality and optimizes the production process through precise grading and efficient impurity removal. It is widely used in the production of special flour such as bread, pastries, and noodles.

Related examples of flour screening machines: Screening process of medium-sized flour processing plants

A medium-sized flour mill adopts a three-pass grinding and two-pass screening process configuration, and the main sections are as follows:

After the first grinding, the material is screened by a linear screen to remove large particles; after the second grinding, the material is screened by a rotary vibrating screen for secondary fineness control;

Finally, the flour is finely screened by an ultrasonic vibrating screen before leaving the warehouse to ensure that the fineness meets the standard and there are no black spots or impurities;

The whole process is closed screening to avoid secondary pollution.

Machine for sieving flour with run through raw material cleaning, particle grading, impurity removal and other links in flour production. Its functions include ensuring product quality, improving production efficiency, meeting diversified market needs, protecting equipment and optimizing process flow. Through the combination of different types of screening machines and multi-layer screens, the flour screening process can efficiently and accurately produce high-quality flour that meets the requirements.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Vibrating screen for gypsum processing

The vibrating screen for gypsum processing is a screening equipment used for particle size grading, impurity removal or dehydration of gypsum...

-

Application of Apatite Vibrating Screen

Apatite vibrating screen is used for screening apatite, mainly because apatite materials have the characteristics of uneven particle size...

-

Centrifugal Sifter For Green Tea Sieving

Centrifugal sifter for green tea sieving Company has launched a new centrifugal sifter for green tea sieving , which aims to provide efficient...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.