Tea sieving machine

![[field:title/]](/uploads/250902/1-250Z2152ZVH.jpg)

Callback

Tea sieving machine is a kind of equipment specially used for grading, removing impurities and sieving tea leaves which is commonly used in tea processing, packaging and other links. The equipment can separate tea leaves of different specifications through multiple layers of screens according to the size, shape and impurity content of the tea leaves.

| Number of layers: 1-5 layers | Motor power: 0.18-2.2kw |

| Mesh number: 500 mesh or 0.028mm | Output: 100-3300 kg/hour |

What is a tea sieving machine?

Tea sieving machine is a mechanical equipment specially used for tea processing. It can grade the size of tea leaves through screens with different apertures. The common sieving mesh number is 10-60 mesh, and the screen aperture ranges from 0.25mm to 2mm to meet the different needs of tea leaves. The equipment can grade tea leaves according to size and coarseness, and at the same time grade the broken powder, tea stems, yellow flakes, etc. to improve the quality of tea leaves and meet the specifications. It is widely used in the primary and refined processing of green tea, black tea, camellia tea and other tea leaves.

Types of tea sieving machines

Tea sieving machine selects different equipment according to the shape of tea leaves. For block tea leaves and granular tea leaves, choose rotary vibrating screen, and for leaf tea leaves, choose linear vibrating screen to ensure that the tea leaves will not be damaged during the screening process. The mesh size range of the equipment for screening tea is 8-200 mesh.

|

Types |

Picture |

Structural features |

Scope of application |

Advantages |

|

Circular vibrating screen (rotary vibrating screen) |

|

Multi-layer circular structure, vibrating motor drive |

fine sieving, small output, multi-specification grading |

small footprint, high sieving accuracy, easy to change the screen |

|

Linear vibrating screen |

|

Rectangular screen frame, dual motor drive, material moves forward in a straight line |

Medium to large output tea sieving |

High sieving efficiency, large processing volume, easy to connect to the production line |

|

Drum screen |

|

Cylindrical structure, motor driven rotation |

Coarse sieving, large impurity removal, pretreatment |

Not easy to block the net, suitable for wet materials or tea with more impurities |

|

Plane rotary screen |

|

Screen box reciprocating plane motion |

Medium High-end tea grading, whole leaves remain intact |

low tea breakage rate, uniform grading |

|

Airflow screen |

|

The screen is in a closed cylinder, graded with the help of airflow and vibration |

tea powder, ultra-fine powder sieving |

dust-free operation, suitable for ultra-fine sieving |

Main functions of tea sieving machine

The tea sieving machine is a kind of equipment used for refined tea processing. It is mainly used to separate the broken pieces, powder, crushed and tea leaves of different sizes and coarseness in tea to improve the quality of tea and meet the specifications.

Grading and sieving: The tea sieving machine can grade tea leaves according to different specifications such as size, coarseness, length, etc. Through screens with different apertures or other sieving mechanisms, the tea leaves are divided into multiple grades, so that the tea leaves of each grade are more uniform in appearance and quality.

Remove impurities: During the picking and preliminary processing of tea leaves, some impurities such as tea stems, yellow leaves, stones, dust, etc. are inevitably mixed in. The tea sieving machine can effectively separate these impurities from the tea leaves, improve the purity of the tea leaves, and improve the appearance and taste of the tea leaves.

Optimize quality: By sieving, tea leaves of different qualities are separated, which helps to adopt different processing techniques and storage methods for different grades of tea leaves, further improve the quality and flavor of tea leaves, and ensure the stability of the quality of tea leaves.

Video of tea sieving machine

What is the working principle of tea sieving machine

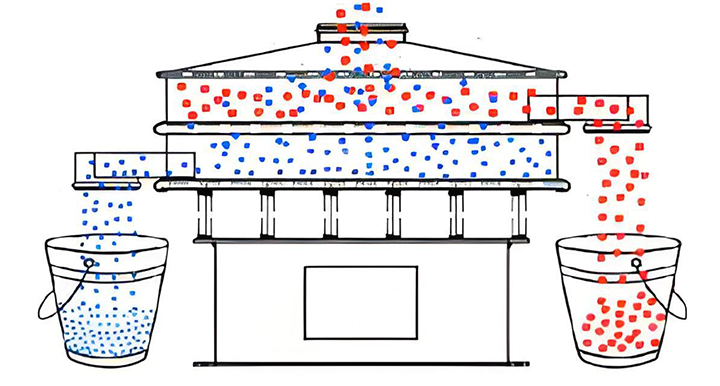

The tea sieving machine uses the three-dimensional composite vibration (horizontal, vertical, inclined) generated by the vibration motor to make the tea rotate and jump on the screen and spread outward. As the machine vibrates, smaller particles will pass through the sieve holes and fall to the lower screen, while larger tea leaves will be retained. This process will continue through multiple layers of screens, and the aperture of each layer of screens will gradually decrease, effectively dividing the tea into different grades.

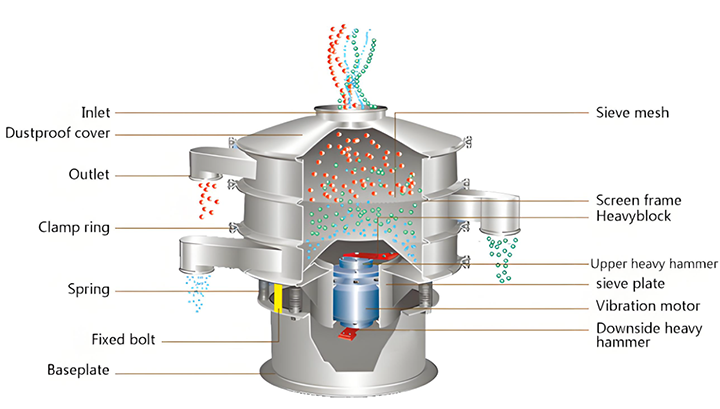

Structural composition of tea sieving machine

Despite different types, most tea sieving machines are composed of the following main components:

Screen/screen frame: used to separate tea leaves of different particle sizes, usually stainless steel mesh, with replaceable mesh.

Screen box/screen body: the main structure that carries the screen and transmits vibration or movement, generally closed or semi-closed.

Vibration motor/drive device: provides the vibration force or rotational power required for sieving, such as vibration motor, eccentric wheel, electric roller, etc.

Shock absorber: includes spring or rubber pad to reduce the impact of vibration on the ground or frame and keep the equipment running stably.

Feed inlet: the entrance of tea material, designed with anti-overflow structure to ensure uniform feeding.

Discharge port: Different screen layers are set with independent discharge ports to output different grades of tea.

Sealing cover (some models): prevent dust leakage or foreign matter from entering, and improve the hygiene and safety of the sieving process.

Frame and support structure: support the weight of the whole machine to ensure stable operation, and some are equipped with mobile casters for easy movement.

Features of tea sieving machine

Tea sieving machine Advantages: 2-5 layers of screens, adjustable vibration system frequency, often closed/semi-closed to reduce dust and tea loss, graded tea leaves are discharged from the discharge port, some of which are adjustable.

Multi-layer screen structure: Most tea sieving machines adopt a multi-layer screen design, usually ranging from 2 to 5 layers. The mesh size of each layer of the screen is different, gradually decreasing from top to bottom, so as to achieve the step-by-step separation of tea leaves of different sizes.

Replaceable screens: In order to adapt to the sieving needs of different types and grades of tea, the screens of the sieving machine can usually be easily replaced. The operator can choose the screen with the appropriate mesh size and material as needed.

Vibration drive system: The sieving machine is usually equipped with an efficient vibration motor or exciter to produce stable vibration, which makes the tea jump and move on the screen surface, so that it can pass through the screen holes smoothly. The vibration frequency and amplitude can usually be adjusted to optimize the sieving effect.

Closed or semi-closed structure: In order to reduce dust flying and keep the working environment clean, many tea sieving machines adopt closed or semi-closed structures. This also helps to reduce the loss of tea.

Adjustable discharge port: Different grades of tea after sieving will be discharged from different discharge ports. The discharge port position and flow rate of some sieving machines can be adjusted to adapt to subsequent collection and processing.

Technical parameters of tea sieving machine

|

Model |

Screen diameter (mm) |

Power (kw) |

Number of layers |

Screen mesh range |

Processing capacity (kg/h) |

|

DH-600 |

560 |

0.25 |

1–3 |

2–500 mesh |

100–800 |

|

DH-800 |

760 |

0.55 |

1–3 |

2–500 mesh |

200–1200 |

|

DH-1000 |

930 |

0.75 |

1–4 |

2–500 mesh |

300–2000 |

Note: The processing capacity is affected by factors such as tea type, moisture content, and screen mesh number.

Recommended mesh number for tea sieving machine

The following is a table of recommended mesh number for tea sieving machine according to different tea types and sieving purposes, which can be used as a reference for equipment selection and production process settings:

|

Tea type |

sieving purpose |

Recommended mesh number (mesh) |

Description |

|

Green tea |

Grading |

10–40 mesh |

Separation of whole leaves and broken leaves |

|

Dust removal |

60–120 mesh |

Removal of tea dust and impurities |

|

|

Black tea |

Grading |

8–30 mesh |

Suitable for larger black tea strip particles |

|

Dust removal |

40–100 mesh |

Removal of stems, broken residues, etc. |

|

|

Oolong tea |

Preliminary sieving |

6– 16 mesh |

remove large foreign matter and coarse tea stems |

|

fine sieving |

30-60 mesh |

fine grading to improve uniformity |

|

|

Black tea (such as Fu brick) |

impurity removal pretreatment |

5-12 mesh |

remove brick debris and coarse impurities |

|

Scented tea |

grading and impurity removal |

10-60 mesh |

suitable for sieving of mixtures, such as jasmine and green tea |

|

Tea powder |

particle control |

60-200 mesh |

control fineness, suitable for tea bag packaging |

|

final sieving |

80-200 mesh |

improve the consistency of tea powder fineness |

Description:

The "mesh" in the value indicates the number of holes per inch of the screen. The larger the value, the smaller the screen hole.

Stainless steel wire woven screens or punched screens are often used in tea sieving. The specific mesh number needs to be adjusted according to the dryness of the tea and the actual particle size.

Multi-layer screens can be selected and used in combination according to needs to achieve simultaneous coarse and fine sieving.

What can a tea sieving machine be used for?

Tea sieving machines are widely used in tea processing and related industries, mainly including:

Tea grade sorting: This is its core function. According to the size and shape of tea leaves, tea leaves are divided into different grades, such as special grade, first grade, second grade, broken tea, flake tea, tea dust, etc. This is crucial to determine the quality and market price of tea leaves.

Remove impurities: Effectively remove non-tea materials mixed in tea leaves, such as tea stems, old leaves, fibers, dust, sediment, metal debris, etc., to improve the purity and safety of tea leaves.

Improve the uniformity of tea leaves: Through sieving, tea leaves of relatively consistent size can be obtained, which not only improves the appearance of tea leaves, but also affects the leaching rate of tea leaves during brewing, thereby affecting the uniformity of taste.

Prepare for subsequent processing links: Graded tea leaves are easier to carry out subsequent processing, such as blending and packaging. For example, tea leaves of different grades can be blended according to market demand, while tea leaves of uniform size are more suitable for automated packaging.

Control product quality: Through precise sieving, the quality standards of the final product can be effectively controlled to ensure that the product meets specific grade requirements.

Selection suggestions for tea sieving machines

It is very important to choose a suitable tea sieving machine, which directly affects the processing efficiency and product quality of tea. Here are some selection suggestions:

Processing volume requirements: First, it is necessary to clarify the amount of tea that needs to be processed every day or every hour. Choose the appropriate machine model and size according to the processing volume to ensure that the processing capacity of the machine can meet the production needs.

Tea types and characteristics: Different types of tea (such as strip tea, curled tea, flat tea, etc.) and different processing stages (primary processing, refining) have different requirements for sieving. It is necessary to consider the shape, humidity, fluffiness and other characteristics of the tea leaves to select the appropriate screen type and vibration method.

Grading requirements: Determine the grade and size range of tea leaves that need to be sorted. Choose the appropriate number of screen layers and mesh size according to the grading requirements. If very fine grading is required, you may need to consider more advanced sieving equipment.

Impurity content: If the impurity content in the raw tea is high, you need to choose a tea sieving machine with good impurity removal effect, and you may need to consider equipment with dust removal or air separation function.

-

Millet vibrating sieve is widely used in millet processing industry, including millet processing plants, rice flour plants, rice......

-

Vibro Sifterfor Powdered Sugar

Powdered sugar vibro sifter is a device for screening sugar powder. It uses vibration to divide sugar

-

Powder Coating Ultrasonic Sieving Machine

The screening accuracy can be increased by 1-70%, and the output can be increased......

-

How to Apply Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine is a fine powder sieving machine with relatively perfect te ...

-

Sunflower seeds screening machine

Sunflower seed screening machine, also known as sunflower seed vibrating screen or separator, is a special equipment ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration ...

-

Sweet potato powder screening machine

The Sweet potato powder screening machine effectively screens, filters and removes sweet potato starch to ensure the quality ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.