What is Banana Sieve

Banana sieve is a vibrating screen with a box vibrator and multiple screen plates with different inclinations. Its core feature is that the screen surface is in a multi-section broken line shape. This unique design makes the screen surface inclination gradually decrease from the maximum (such as 25-34 degrees) at the feed end to the minimum (such as 5-10 degrees) at the discharge end. Its main function is to classify, desludging, dehydrating, and de-mediuming various minerals, coal and other materials. It is particularly good at handling difficult-to-screen materials with high fine particle content, high moisture content or easy to block holes.

Banana sieve has high grading accuracy, especially for medium and fine particle materials. Compared with traditional linear vibrating screens, the processing capacity (output) of banana sieves can usually be increased by 1.5 to 2 times, ensuring that the thickness of the material layer on the screen surface is basically uniform, increasing the chance of fine particles contacting the screen surface.

The difference between banana sieve and traditional linear vibrating screen

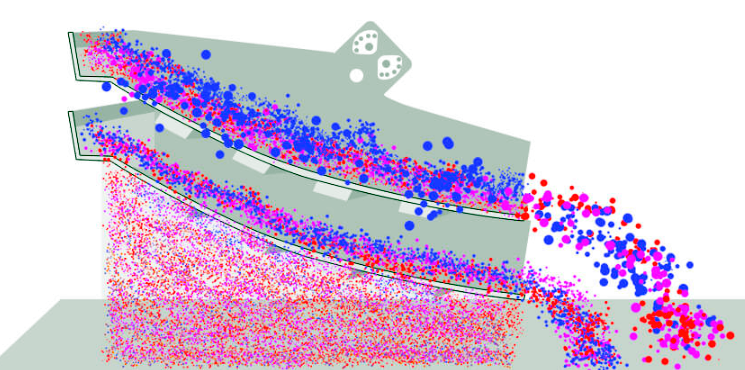

Banana screen: It is usually composed of 2-6 sections of screen surfaces with different inclinations, gradually transitioning from the steep angle at the feed end (such as 30°-45°) to the gentle angle at the discharge end (such as 0°-10°). In the steep section, the material flow rate is fast, the layer thickness is thin, and the fine material is quickly layered and screened out; in the gentle section, the material flow rate slows down, increasing the chance of particle penetration.

Applicable particle size range: mostly medium and coarse particles (0.1~150mm) material screening

Screening efficiency: high, 1.5-2 times higher efficiency than traditional screens, and large processing capacity per unit area (up to 2500 tons/hour).

Processing capacity: Very high: Under the same screening area, the processing capacity is usually 1.5-2 times higher than that of traditional screens, or even more.

Traditional linear vibrating screen: The screen surface is usually straight, the whole is horizontal or has a fixed inclination angle (such as 5°-25°). The screen surface is usually straight, the whole is horizontal or has a fixed inclination angle (such as 5°-25°).

Applicable particle size range: It can be used for coarse, medium and fine particle screening, but the efficiency is low

Screening efficiency: Low, limited processing capacity, suitable for small and medium-sized production.

Processing capacity: Relatively low, when processing large processing capacity, a larger screening area is required.

What is the working principle of the banana sieve

The motor and the exciter are used as vibration sources. The two sets of eccentric masses in the exciter are equal and run synchronously in the opposite direction. At each instantaneous position, the centrifugal force generated by the two sets of eccentric masses always superimposes on each other along the vibration direction to form a single-direction excitation force, so that the screen box reciprocates linearly. The screen surface relies on linear movement in both horizontal and vertical directions to achieve forward and backward movement and screening of materials, so that the materials are continuously layered and screened during the vibration process.

What are the advantages of banana sieve?

The banana sieve adopts a large vibration intensity and a unique screen surface design, which makes the material move fast on the screen surface and pass a large amount of material. It can meet the screening needs of large amounts of materials and increase the processing capacity by 1-2 times compared with the vibrating screen with the same effective area. The ratio of material quantity to flow rate on each section of the screen is stable, the material layer height is uniform, fine-grained materials can be screened faster, and the screening efficiency is significantly improved, usually the screening efficiency can be greater than 95%.

Recommended mesh number of banana sieve

|

Mesh number (mesh) |

Sieve hole size (mm) |

Applicable particle size range (mm) |

Typical application materials |

|

2–4 |

5.6–4.75 |

>6 |

Preliminary screening of raw coal and stone |

|

5–8 |

4.0–2.36 |

4~8 |

Pre-screening of iron ore and sintered ore |

|

10–20 |

2.0–0.85 |

1~4 |

Gravel aggregate classification |

|

30–40 |

0.6–0.425 |

0.5~1.5 |

Classification before concentrate dehydration |

|

50–70 |

0.3–0.21 |

0.2~ 0.6 |

Fine coal desludging, heavy medium screening |

|

80–100 |

0.18–0.15 |

0.15~0.3 |

Fine classification, industrial salt classification |

|

120–200 |

0.125–0.075 |

0.075~0.15 |

Concentrate recovery, fine particle dehydration |

The actual mesh selection should be determined based on the material particle size distribution, processing capacity, screening purpose (classification/dehydration/desludging) and equipment model; banana sieves are mostly used for coarse screening or medium-coarse screening processes, and banana sieves are rarely used for fine screening (above 100 mesh).

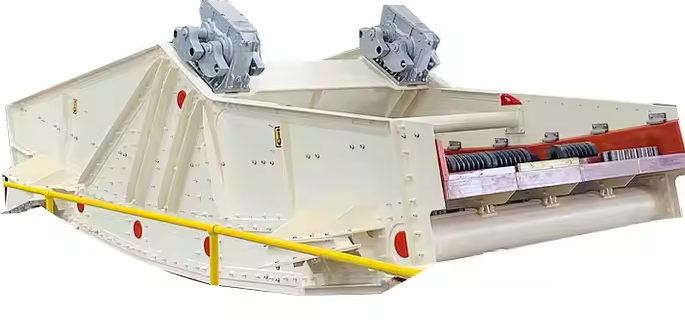

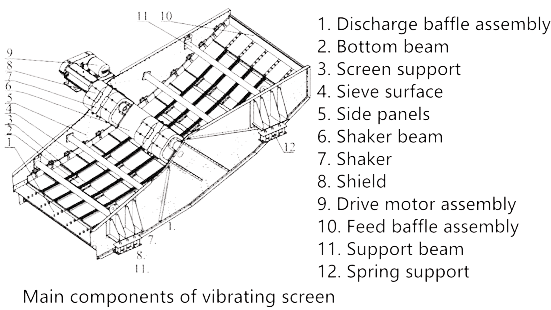

What is the structure of the banana sieve?

Banana sieve, also often called multi-angle vibrating screen, has a unique structural design. Its core components include screen box, screen surface/screen plate, vibrator, vibration reduction device/support system and drive device.

The screen box is usually made of high-strength steel to withstand the vibration and material load generated during the screening process. The screen surface/screen plate consists of multiple (usually 5-6 sections) screen plates with different inclinations. The inclination is the largest at the feed end (up to 30-34 degrees), and then gradually decreases to the discharge end (up to 5-10 degrees).

The exciter is the core component that generates vibration, usually including an eccentric shaft, pulley, bearing and bearing seat. The drive unit provides power and is connected to the exciter through a belt or coupling to drive it to rotate and generate vibration.

Technical parameters of banana sieve

|

Model |

Screen width (mm) |

Screen length (mm) |

Number of layers |

Screen inclination (°) |

Screen hole size (mm) |

Processing capacity (t/h) |

Motor power (kW) |

|

BS1236 |

1200 |

3600 |

1~2 |

34°/25°/15° |

2~50 |

80~200 |

2×11 |

|

BS1848 |

1800 |

4800 |

1~2 |

30°/20°/12° |

2~60 |

150~350 |

2×15 |

|

BS2461 |

2400 |

6100 |

1~2 |

30°/20 °/10° |

3~80 |

300~800 |

2×22 |

|

BS3061 |

3000 |

6100 |

1~2 |

25°/15°/5° |

5~80 |

500~1200 |

2×30~2×37 |

|

BS3673 |

3600 |

7300 |

2~3 |

Multi-stage combination 0~35° |

5~80 |

800~1500 |

2×37~2×45 |

What can banana sieves be used for

Banana screens are widely used for screening and processing of heavy-loaded and high-yield materials because of their multi-section curved screen surface, large processing capacity and screening efficiency.

In coal mine washing systems, banana sieves are often used to pre-screen raw coal, separate large pieces of coal, impurities and coal slime, and reduce the burden on subsequent equipment. It is also commonly used in coal slime dehydration or de-mediuming processes. The curved screen surface allows the coal slime to be quickly layered to improve screening efficiency.

In the beneficiation processes of iron ore, manganese ore, lead and zinc ore, banana sieves are used for pre-screening before coarse or medium crushing, effectively separating qualified particle sizes, improving crusher processing efficiency, and reducing energy consumption. Banana screens are also suitable for fine grading and particle size control of aggregates such as machine-made sand and gravel.

Banana sieve operation rules

The operation of banana sieve must strictly follow the rules to ensure safety. Before starting, check the screen box, screen, vibrator, spring and transmission system to confirm that there are no cracks, looseness or wear, sufficient lubricating oil, and reliable grounding of electrical equipment. Check the parameters such as the screen surface inclination (25°-34° at the feeding end and 3°-10° at the discharging end), amplitude (3-15mm), and clean the residual material on the screen surface.

When starting, first run it without load for 2-5 minutes, observe that the vibration is stable and there is no abnormal sound, and then feed slowly and evenly to avoid concentrated impact and keep the material layer thickness 2-3 times the screen hole. During operation, inspect every 1-2 hours, monitor the blockage of the screen, the temperature of the vibrator (bearing ≤75℃), the motor current and the amplitude stability, and listen for any abnormal sounds. Wet and sticky materials need to increase the amplitude or adjust the inclination appropriately to prevent adhesion.

Stop feeding before stopping, and turn off the power after the screen surface material is emptied. Clean the sieve holes regularly, check the bolts and springs, and add lubricating oil to ensure long-term and stable operation of the equipment and extend its service life.Because of its large processing capacity and clear screening levels, it is often used in large aggregate production lines to control the particle size of finished materials and improve product consistency.

In the steel smelting process, sintered ore and pelletized ore need to be screened according to particle size after cooling. Banana screens can achieve large-throughput grading under high-speed vibration to ensure uniform and stable charge. Power plant boilers have strict requirements on coal powder particle size. Banana screens are used for screening before boiler coal combustion to screen out unqualified particles.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Vibrating screen for gypsum processing

The vibrating screen for gypsum processing is a screening equipment used for particle size grading, impurity removal or dehydration of gypsum...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.