Stainless steel straight screen

What is Stainless Steel Straight Screen?

Stainless steel straight screens are made from high-strength stainless steel wire using a precision plain or twill weave process, resulting in a stable structure and uniform pore size. Key parameters include precisely controlled pore size (adjustable from 0.02mm to 10mm), a high porosity (30%-60%), and a balanced wire diameter ratio (wire diameter ≤ 1/3 of the pore size) to ensure efficient filtration and deformation resistance. During the manufacturing process, fully automated CNC weaving equipment ensures dimensional accuracy of ±0.1mm. Argon arc welding is used to reinforce the frame and mesh seams. Polishing and pickling passivation treatments result in a smooth, corrosion-resistant surface.

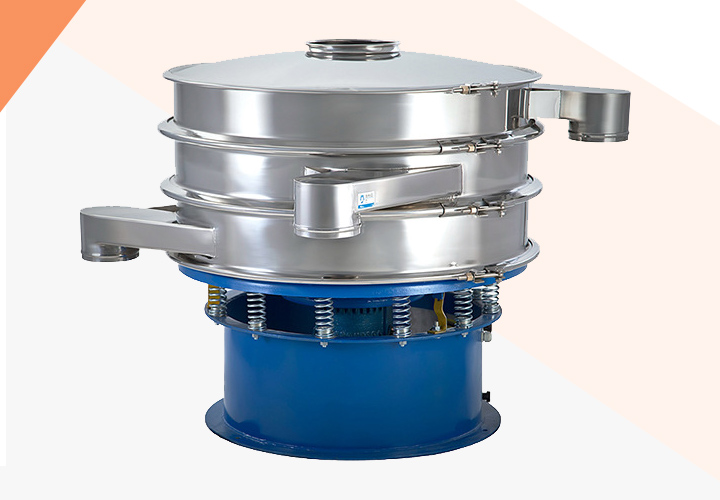

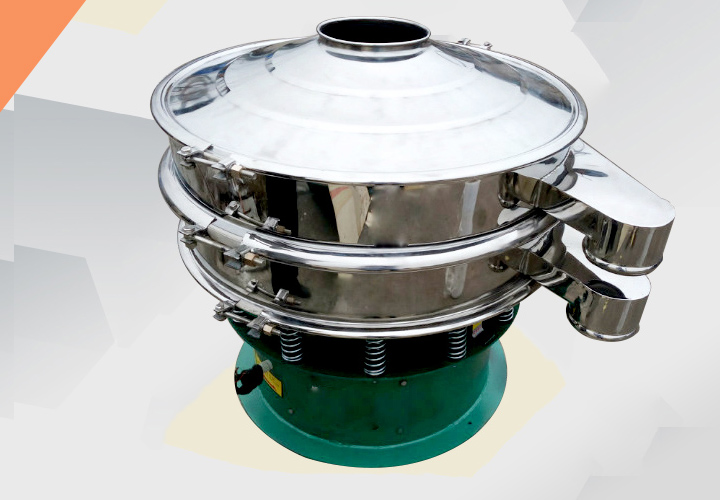

Stainless steel straight screen is an efficient and durable screening equipment, mainly used for rapid screening of powder or granular materials, and is widely used in chemical, food, pharmaceutical, metallurgical and other industries. It adopts a straight-discharge design and stainless steel material. The feed and discharge ports are located in a vertical direction, and the material can be quickly discharged through the screen, which improves the screening efficiency and processing capacity. The main components are made of stainless steel, which has the characteristics of corrosion resistance, sanitation and safety, and strong durability. It can significantly improve the screening efficiency and reduce the labor intensity.

Video of stainless steel straight screen

What is Working principle of stainless steel straight screen?

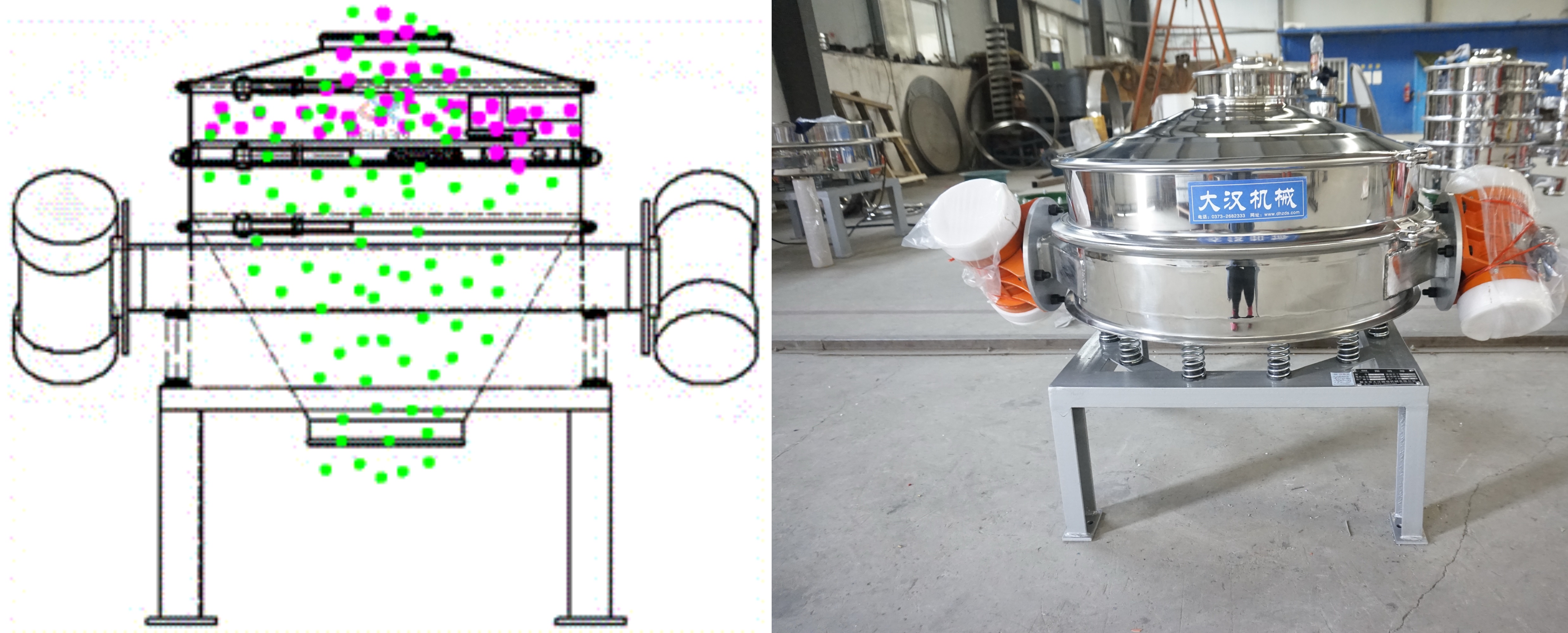

Stainless steel straight screen usually uses vibration motor as excitation source, which is installed on one or both sides of the screen body. The vibration generated by the vibration motor makes the screen produce high-frequency vibration. After the material enters the screen machine, it passes through the screen quickly under the action of vibration force. Qualified materials pass through the screen and are discharged from the bottom outlet, while unqualified materials remain on the screen and are discharged from the outlet on the screen.

What are the advantages of stainless steel straight-discharge screens?

Stainless steel straight screen can reduce material residue, avoid material blockage, adapt to different material characteristics, solve the problem of poor material fluidity, and improve screening efficiency and accuracy.

Reduce material residue: The screen body of stainless steel straight screen adopts an inclined design, and the discharge port is located at the lower end of the screen body. The material can be quickly discharged from the screen body under the action of gravity, reducing the residue of the material in the screen body. The inclination angle of the screen body is generally between 5°-15°, which can be adjusted according to the fluidity of the material.

Avoid material blockage: A scraper is set inside the screen body, which can scrape the material on the screen surface in time and push it to the discharge port to ensure that the material can be quickly and thoroughly discharged from the screen body. For some materials with high viscosity and easy accumulation, a spiral discharger can be installed at the discharge port to avoid material blockage and residue at the discharge port.

Handle differences in material characteristics: The particle size, humidity, viscosity and other characteristics of different materials vary greatly, and the requirements for screening equipment are also different. stainless steel straight screen has strong adaptability and can adapt to different materials by adjusting parameters and replacing the screen. It can be customized according to customer needs to meet specific screening requirements.

Solve the problem of poor material fluidity: The in-line design of stainless steel straight screen allows the material to pass through the screen quickly, increasing the processing capacity. By adjusting the parameters of the vibration motor, optimizing the vibration frequency and amplitude, the screening efficiency can be improved. Select the appropriate screen according to the material characteristics to ensure screening accuracy and efficiency.

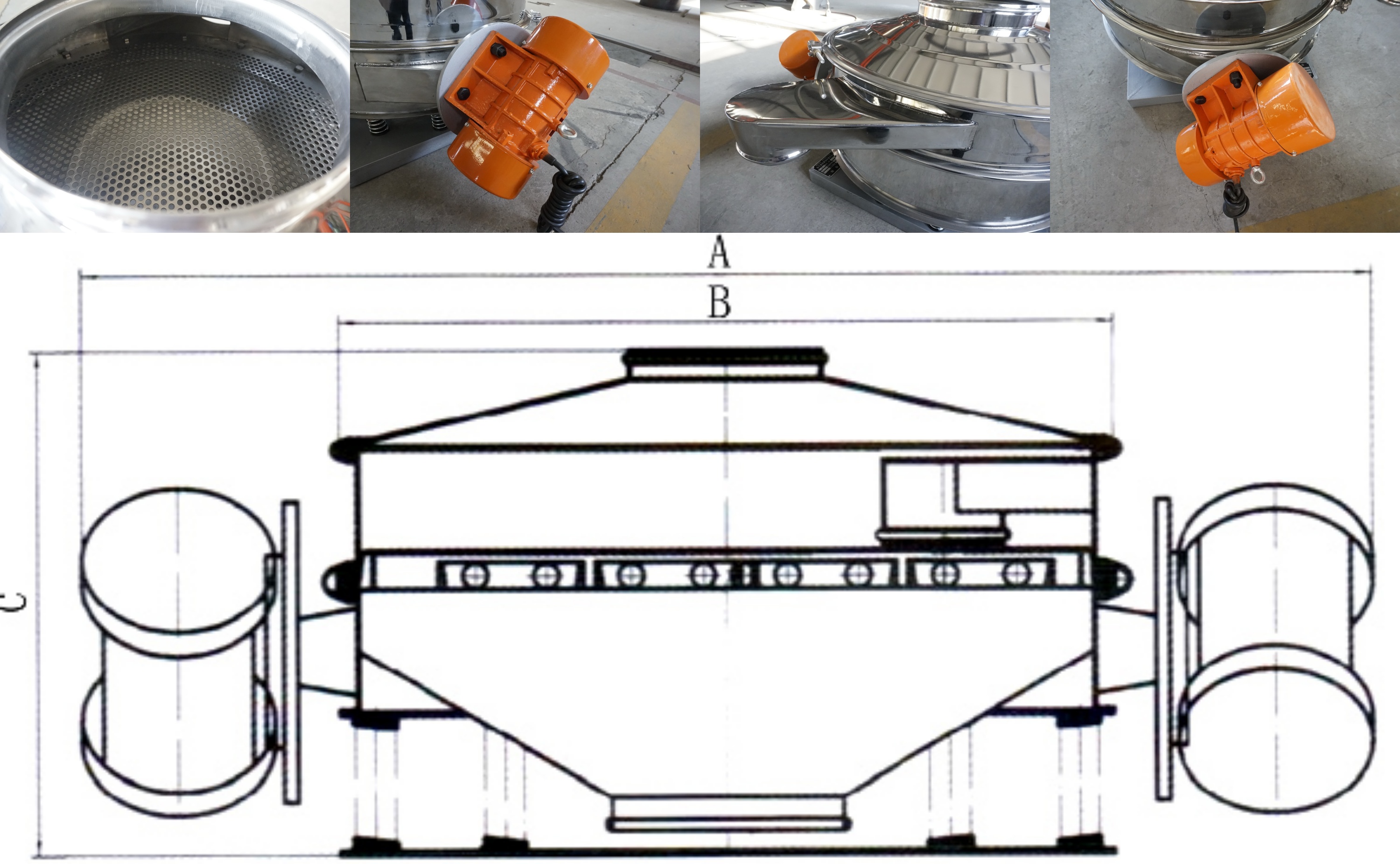

Technical parameters of stainless steel straight screen

| Model | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| ZPS-600 | 600 | 150 | 380 | 560 | 325 | 120 | 80 |

| ZPS-800 | 800 | 200 | 540 | 600 | 350 | 125 | 90 |

| ZPS-1000 | 970 | 250 | 640 | 640 | 350 | 150 | 100 |

| ZPS-1200 | 1170 | 250 | 700 | 700 | 400 | 180 | 120 |

| ZPS-1500 | 1470 | 250 | 760 | 760 | 440 | 200 | 120 |

What types of stainless steel straight screens are available?

Stainless steel straight screen can be divided into single motor and double motor according to the vibration source, standard type and all stainless steel type according to the material, and removal type and classification type according to the screening purpose. There are also linear vibrating screens and three-dimensional vibrating screens.

Classification by Vibration Source

Single-Motor Linear Screen: Powered by a single vibrating motor, this screen offers low operating costs. The screen body performs linear reciprocating motion and is suitable for screening general granular and powdered materials, such as grain and plastic pellets. It is suitable for small- to medium-scale production and low-throughput applications. It offers moderate screening efficiency and low energy consumption.

Dual-Motor Linear Screen: Equipped with two synchronous, counter-rotating vibrating motors, this screen generates a powerful, directional vibration force. It offers adjustable screening intensity and a high throughput, making it suitable for handling heavy, viscous, or difficult-to-screen materials, such as ore and quartz sand. The dual-motor design ensures more uniform force distribution on the screen, effectively extending its service life and making it suitable for high-intensity, continuous operation.

Classification by Material

Standard Stainless Steel Linear Screen: The screen frame, screen mesh, and other material-contacting areas are constructed of 304 stainless steel for excellent corrosion resistance. The base and bracket are constructed of carbon steel to reduce costs. This screen is suitable for industries with moderate hygiene requirements, such as the chemical and building materials industries.

All-Stainless Steel Straight Screen: The entire unit is constructed of 304 or 316L stainless steel, with all welds polished to eliminate sanitary blind spots. It complies with GMP and FDA standards and is suitable for use in industries with stringent hygiene requirements, such as food, pharmaceuticals, and dairy products, meeting aseptic production requirements.

Classification by Screening Purpose

Removal Straight Screen: Its primary function is to remove impurities, lumps, and foreign matter from the material. The screen mesh is typically low (10-60 mesh). It is widely used in raw material pretreatment processes, such as flour impurity removal and plastic pellet deslagging.

Grading Straight Screen: This screen uses multiple layers (usually 2-5 layers) of screen mesh to precisely grade the material, with mesh configurations ranging from coarse to fine (e.g., 20-200 mesh). It is suitable for industries requiring multi-level particle size control, such as fertilizer grading and powder coating screening, and can simultaneously produce a variety of product specifications.

Other Vibrating Screen Types

Stainless Steel Linear Vibrating Screen: It utilizes a rectangular screen surface, with the material bouncing across the screen in a linear motion, and can handle over 10 tons/hour. It is particularly suitable for large-scale continuous screening in automated production lines, such as in grain processing and metallurgical raw material handling.

Stainless Steel 3D Vibrating Screen: A vertical vibrating motor generates multi-dimensional, compound motion, causing the material to spread in a spiral pattern across the circular screen surface. With a screening accuracy exceeding 500 mesh, it is suitable for fine screening of high-value-added materials, such as traditional Chinese medicine powder and silica powder, among other specialized applications.

The structure of stainless steel straight screen

The structure of stainless steel straight screen is mainly composed of several core parts such as the screen frame, screen mesh, vibration motor, screen box, base, screen cleaning device, sealing device, etc. Each part plays a vital role and jointly ensures the efficiency and accuracy of screening.

What industries use stainless steel straight screens?

Chemical industry: used to screen chemical raw materials (such as resins, pigments, coatings, etc.), remove impurities and oversized particles. Ensure the purity and uniformity of chemical raw materials, improve production efficiency and product quality.

Food industry: used to screen food raw materials (such as flour, powdered sugar, starch, etc.), ensure the uniformity and quality of food. Remove impurities and oversized particles in food raw materials to ensure the safety and taste of food.

Pharmaceutical industry: used to screen pharmaceutical raw materials (such as powder, granules, etc.), ensure the uniformity and quality of pharmaceuticals. Remove impurities and oversized particles in pharmaceutical raw materials to ensure the safety and effectiveness of pharmaceuticals.

Metallurgy and mining: used to screen metal powders, ores, etc., remove impurities and oversized particles. Ensure the uniformity and quality of metal powders and ores, improve production efficiency and product quality.

Building materials industry: used to screen building materials raw materials (such as cement, lime, gypsum, etc.), ensure the uniformity and quality of building materials. Remove impurities and oversized particles in building materials raw materials to ensure the quality and performance of building materials.

Stainless Steel Straight Screen Customer Case Study

A food processing company selected a stainless steel straight screen for flour screening to improve production efficiency. The screen, made of 304 stainless steel, is corrosion-resistant, easy to clean, and fully meets food-grade hygiene standards. Its high-precision screening capability significantly improves flour fineness, while its wear-resistant design extends its service life and reduces maintenance costs. Customer feedback indicates stable operation, a 30% increase in screening efficiency, and significant reduction in raw material waste.

Stainless steel straight screen supplier

There are many suppliers of stainless steel straight screens. Dahan Machinery can provide material certificates and is proficient in screen weaving technology (plain weave, twill weave, mat weave, etc.) and edge treatment processes (such as welding and edge binding). Furthermore, it can provide precise selection advice and non-standard customization services based on specific working conditions such as the material being screened, flow rate, pressure, temperature, and corrosiveness. You can contact our staff online to bring your materials to our factory for testing and inspection.

Stainless steel straight screen can effectively solve various problems encountered in the material screening process through its unique design and material advantages, and improve screening efficiency and product quality.

-

The model of vibration sieve is divided into eight equipments with different dimensions from 400-2000mm.

-

Sieve machine is a general-purpose vibrating screening and filtering equipment. The main material is divided into SUS304 stainless steel or Q235A carbon steel.

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

63 filter screen

63 filter screen usually refers to a filter screen with a pore size of 63 microns (µm). 63 microns refers to the size...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Small vibrating screener

Small vibrating screener is a kind of equipment used for screening and grading granular materials. It uses the..

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

-

Chemical catalyst vibrating screen

Chemical catalyst vibratinACg screen is a device specially used for screening and grading chemical catalyst...

-

63 filter screen

63 filter screen usually refers to a filter screen with a pore size of 63 microns (µm). 63 microns refers to the size...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Nylon sieve

Nylon sieve is a common screening tool, widely used in laboratories and industrial production, mainly used for screening...

-

Small vibrating screener

Small vibrating screener is a kind of equipment used for screening and grading granular materials. It uses the..

-

Stone powder vibrating screen

Drying sand vibrating screen is a screening device that uses the exciting force generated by the vibrating motor to...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.