Square Linear Vibrating Screen for Mica Powder

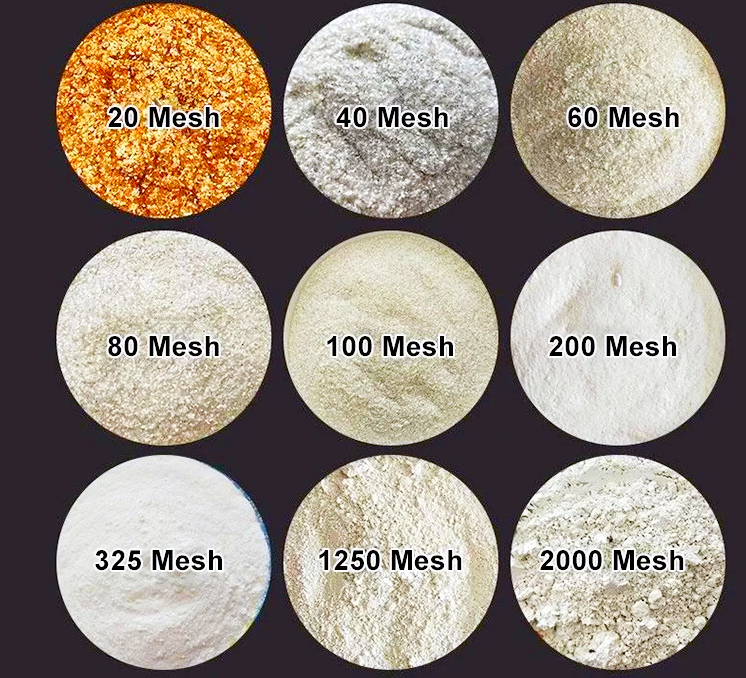

The square linear vibrating screen for mica powder is an efficient screening equipment designed for the characteristics of mica powder. It is driven efficiently by a vibrating motor to make the tray move in a straight line. It is suitable for uniform particle size, uniform adjustment and solid-liquid separation of mica. Mica powder is a fine-grained non-metallic mineral (particle size 325 mesh to 5000 mesh, about 44μm to 2.8μm), with a flaky structure, high diameter-thickness ratio, strong suspension, pearlescent effect, and strict requirements on particle size distribution. The equipment has high screening accuracy and strong processing capacity, is suitable for continuous operation, can effectively separate mica powder of different particle sizes, and ensure screen storage. The structure usually includes a single layer or its graded screen (commonly 1-5 layers), with a flexible structural design, which can be adjusted according to particle size requirements to meet fine screening requirements. The equipment runs stably and maintains a high degree of stability, making it an ideal choice for mica powder processing.

The difference between the square linear vibrating screen and the linear vibrating screen for mica powder

There are some differences in design and application between the rectangular linear vibrating screen for mica powder and the ordinary linear vibrating screen, especially when dealing with the storage of fine particles and flaky structures such as mica powder.

Linear vibrating screen

It is mainly used for grading or removing impurities of granular and powdery dry materials, and has a wide range of applications (such as ores, chemical raw materials, grains, etc.), but the targeted design for fine particles and special physical structure materials is insufficient. It is only suitable for coarse-grained mica powder (such as below 325 mesh, particle size > 44μm). Because the screen accuracy is low (usually ≤300 mesh) and it is not optimized for flaky structures, it is easy to cause low screening rate of fine-grained mica powder or blockage.

Square linear vibrating screen for mica powder

Designed for fine-grained, flaky mica powder (processing range covers 325 mesh to 5000 mesh, particle size 44μm to 2.8μm)

Adopt high-precision stainless steel woven mesh or punching plate (up to 5000 mesh, corresponding to 2.8μm aperture), adapted to the extremely fine particle size requirements of mica powder. Combined with the characteristics of mica powder flake and high diameter-thickness ratio, by tilting the screen surface angle, adding a bouncing ball cleaning device or an ultrasonic cleaning system, the screen blockage is reduced and the fine powder screening efficiency is improved.

|

Project |

Mica powder square linear vibrating screen |

Ordinary linear vibrating screen |

|

Number of screening layers |

Usually 2 to 5 layers, can be used for multi-level particle size sorting |

Usually 1 to 4 layers, the classification is relatively rough |

|

Screening accuracy |

High accuracy, suitable for mica powder screening with strict requirements on particle size distribution |

Medium accuracy, difficult to accurately control the fine particle size distribution |

|

Processing capacity |

The screen area can be customized according to needs, taking into account both accuracy and output |

High output, but the fine powder screening efficiency may be low |

Working principle of square linear vibrating screen for mica powder

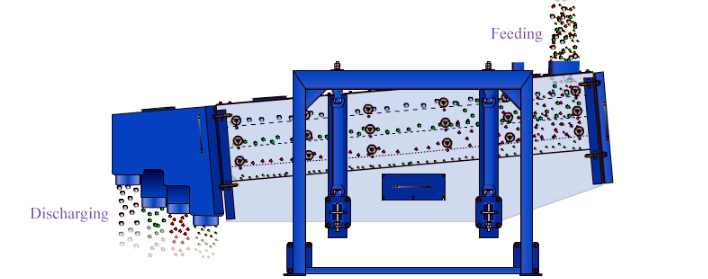

Square linear vibrating screen usually uses two identical vibration motors as vibration sources, and the vibration motors fixed on the screen box rotate synchronously in opposite directions.

The centrifugal force generated by the eccentric block of the vibration motor at each instant of rotation reciprocates in the throwing direction, causing the entire screen supported on the shock absorber to vibrate linearly, so that the material is thrown up on the screen surface and moves forward linearly.

After the material falls into the screen frame from the feed end, it moves forward quickly and loosely through the screen to complete the screening operation.

What are the advantages of square linear vibrating screen for mica powder screening

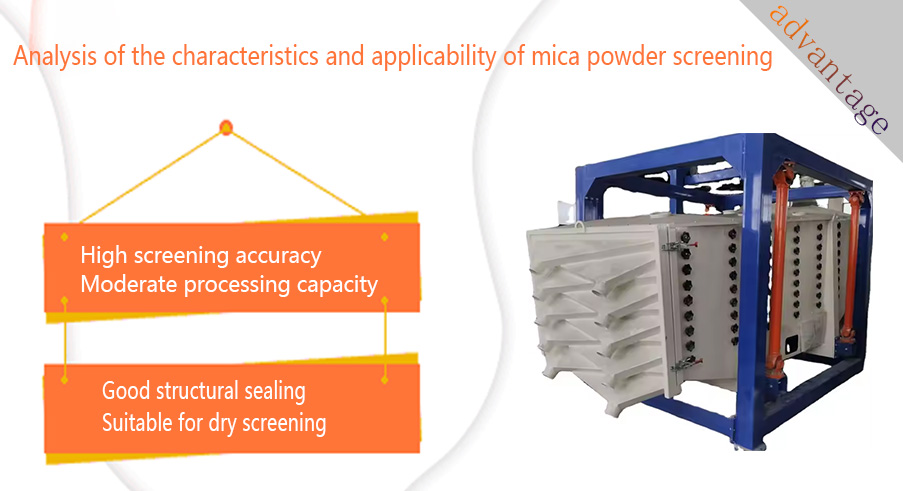

The square linear vibrating screen for mica powder has significant advantages in screening mica powder, meeting its flaky structure, lightweight characteristics and screening needs.

High screening accuracy: The screen area is large, supporting graded screen density (usually 1-5 layers), which can achieve multi-level particle size classification, accurately separating mica powder from 325 to 5000 mesh (44μm to 2.8μm), meeting the strict requirements of particle size distribution in industries such as coatings, plastics, and rubber.

Moderate processing capacity: Suitable for small and medium batch production, the fine mesh length and width can be efficiently customized, flexibly adapting to the processing needs of mica powder, ensuring the completion of high-precision size and adjustment.

Suitable for dry screening: Optimized for particle size classification and refinement of dry mica powder, avoiding screen siltation, especially suitable for high-standard screening needs in the fine chemical and cosmetic industries.

Recommended mesh number of square linear vibrating screen for mica powder

|

Industry/Application |

Recommended mesh number |

Particle size range (μm) |

Remarks |

|

Coating/Paint |

325 mesh - 800 mesh |

44 - 15 |

Ensure smooth coating and even dispersion, suitable for medium and high-end coatings |

|

Plastic/Rubber |

200 mesh - 600 mesh |

74 - 25 |

Used to enhance material strength and surface gloss, and avoid excessively fine particles affecting processing |

|

Cosmetics (such as pearlescent powder) |

800 mesh - 1250 mesh |

15 - 10 |

Ultrafine screening, ultrasonic cleaning device is required to prevent clogging and ensure fine powder |

|

Electronic materials/Insulating materials |

600 mesh - 2000 mesh |

25 - 7 |

High purity requirements, suitable for high-precision electronic products |

|

Ceramics/Glass |

100 mesh - 400 mesh |

150 - 38 |

Applicable to coarse mica powder, emphasizing high-throughput screening, suitable for large-scale production |

|

Ultrafine mica powder (such as 5000 mesh) |

1250 mesh-5000 mesh |

10-2.8 |

Suitable for high-end applications (such as nano-grade materials), with extremely high requirements for equipment precision |

Scope of application

The square linear vibrating screen for mica powder is not only suitable for the precise screening of mica powder (such as ultra-fine powder classification from 325 mesh to 5000 mesh), but also widely adapts to the screening needs of various dry particles and powder materials. Its scope of application covers the field of mineral processing, such as particle size classification and impurity removal of non-metallic mineral powders such as quartz sand, talcum powder, kaolin, and wollastonite; the food industry, including the screening and purification of food raw materials such as soybean powder, powdered sugar, and starch to ensure particle uniformity; the chemical industry, suitable for the precise screening and homogenization of materials such as plastic powder, coating powder, and resin particles, and can also separate solid-liquid mixed materials.

The equipment, with its multi-level screen design (usually 3-5 layers), high-precision anti-blocking technology and closed structure, can efficiently process materials with different particle size ranges (1μm to several millimeters), meet the stringent requirements of various industries for particle size distribution, impurity control and continuous production, and is a universal solution in dry screening scenarios.

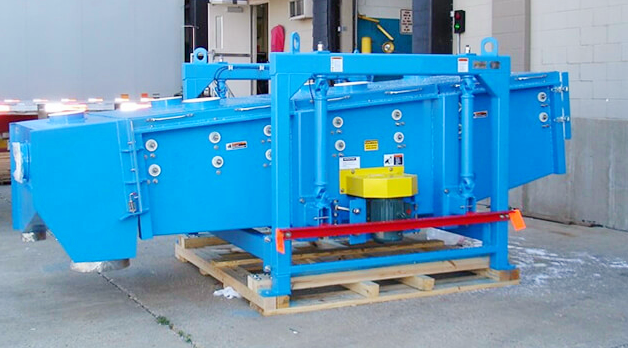

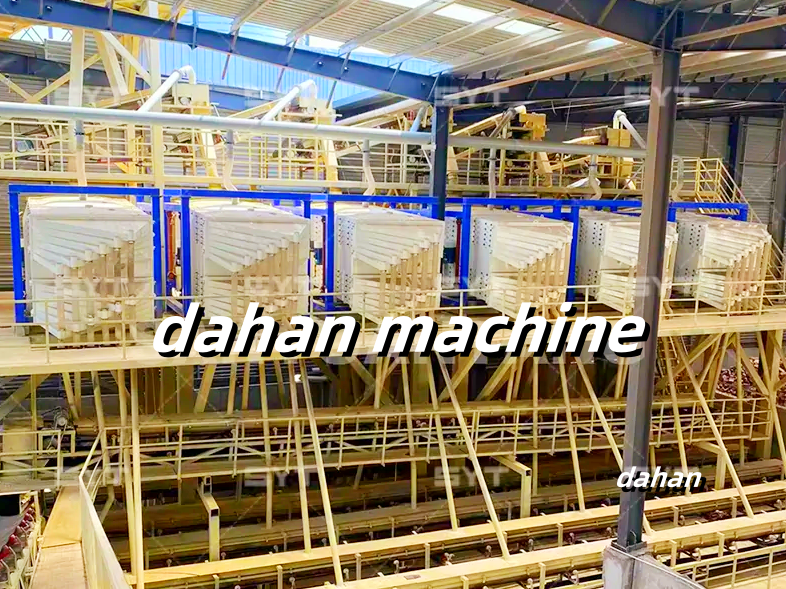

Manufacturer of square linear vibrating screen for mica powder

In the field of mica powder screening equipment, dahan Machinery has become a highly regarded presence in the industry with its deep technical accumulation and rich production experience. The company has been established for many years and has always focused on the research and development, production and sales of vibration screening equipment, and has established a good reputation in the industry. The products are widely used in the classification, impurity removal and solid-liquid separation of mica powder and other materials, with the characteristics of efficient screening, high precision, and suitable for continuous operation.The equipment supports multiple layers of screens (1-5 layers) and can be flexibly customized according to the particle size requirements of mica powder. The core function of square linear vibrating screen for mica powder is to achieve accurate particle size classification and impurity removal of mica powder to meet the requirements of mica powder product quality and specifications in different industries.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Granules, powders, and paddle materials can be used.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Meet the needs of large-scale and high-precision screening

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Chemical liquid vibrating screen

Chemical liquid vibrating screen is a device used for solid-liquid separation or liquid filtration...

-

Circular swing screen

Circular swing screen, also known as swing screen or shaking screen, is a low-frequency rotary vibration...

-

Plastic granules square swing screen

Plastic granules square swing screen is a low-speed, high-precision vibration screening device specially...

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.