Sieving Machine for Copper Electrolytic Powder

According to the application requirements of copper powder, high-precision grading screening of 100 mesh, 200 mesh, 300 mesh and even 500 mesh is often required to ensure the consistency and purity of product particle size. In order to achieve effective grading of copper powders of different particle sizes, the sieving machine is usually designed as a 1-3-layer screen structure, which can complete the multi-stage separation of coarse powder, finished powder and fine powder at one time. "About 80 words, including the mesh number, briefly summarized in one paragraph

What is the role of the sieving machine for copper electrolytic powder

Copper electrolytic powder is a copper powder produced by electrolysis. Its preparation process usually includes smelting, electrolysis, washing, surface treatment, drying and screening. Electrolytic copper powder has the characteristics of low lead content, low bulk density and developed dendritic structure, which makes it excellent in conductivity and is particularly suitable for the electric carbon industry. In the production process of electrolytic copper powder, screening is an important step for controlling the particle size distribution of copper powder.

The sieving machine ensures that the particle size of the electrolytic copper powder meets specific requirements, because different applications have different requirements for the particle size of copper powder. For example, fine copper powder may be more Suitable for some conductive slurries, while coarser copper powder may be used in some powder metallurgy processes. Through screening, particles that are too large or too small can be removed, thereby obtaining high-quality electrolytic copper powder with uniform particle size distribution.

What are the types of copper electrolytic powder sieving machines?

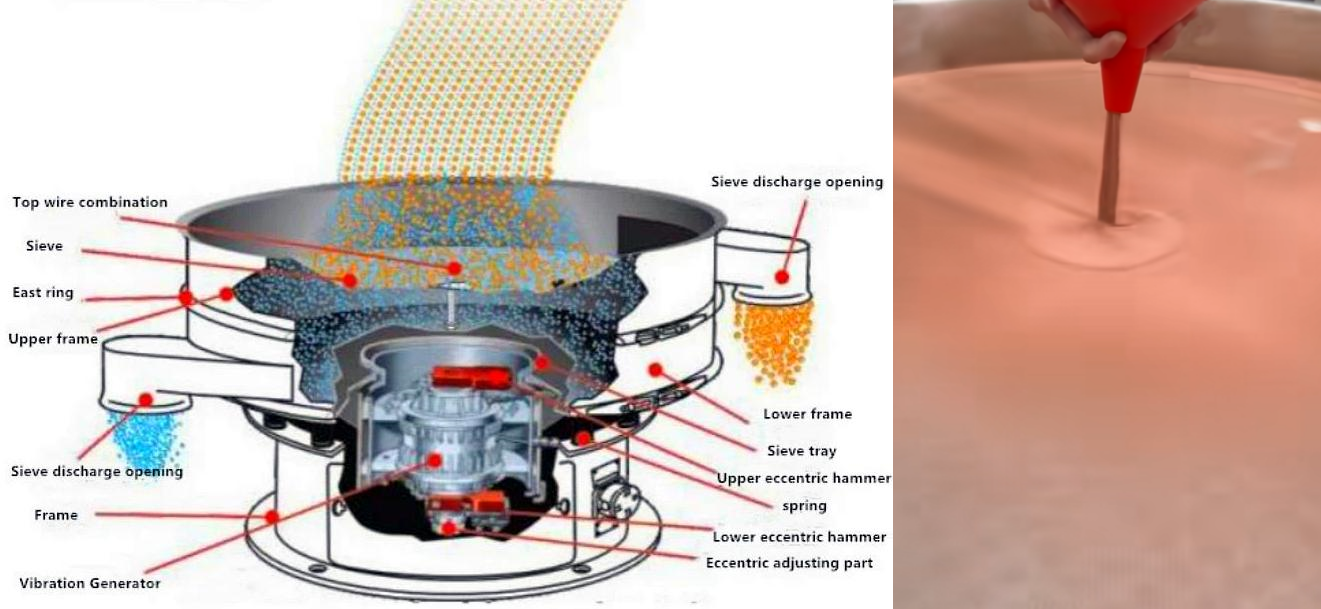

Sieving machines for copper electrolytic powder usually use vibration screening technology to separate materials of different particle sizes through different apertures of the screen. This sieving machine can efficiently divide copper powder into multiple levels according to particle size, which is convenient for subsequent processing or direct application.

|

Project |

Swing screen |

Ultrasonic vibrating screen |

|

Picture |

|

|

|

Working principle |

Simulate manual screening action, the material is elliptical swing motion |

Ultrasonic high-frequency vibration system is superimposed on the basis of ordinary vibrating screen |

|

Applicable particle size range |

20μm ~ 5 mm (suitable for medium and fine particles) |

Below 20 μm~ 300 μm, suitable for fine powder |

|

Screening accuracy |

High, up to more than 95% |

Extremely high, up to 95%~98%, especially effective for blocking powder |

|

Processing capacity |

Large, suitable for large-scale processing (such as 500~5000 kg/h) |

Medium, suitable for small and medium production (100~1000kg/h) |

|

Number of layers configuration |

5 layers or more can be configured to achieve multi-level sorting |

Usually 1~3 layers, too many layers will affect ultrasonic conduction |

|

Applicable copper powder types |

Granular, electrolytic agglomerated powder, large-scale classification |

Fine copper powder, high-purity copper powder, light or easy-to-block powder |

|

Applicable working conditions |

High production requirements, multi-level screening requirements |

High precision requirements, easy-to-block screen, extremely fine particle size or electrostatic materials |

Swing screen: more suitable for large-scale screening of medium and large-size electrolytic copper powder, especially when multi-level particle size control is required, such as copper powder screening to 20 mesh, 60 mesh, and 100 mesh.

Ultrasonic vibration screen: more suitable for high-precision and ultra-fine mesh screening, such as screening 300 mesh, 400 mesh or finer copper powder, to avoid clogging and improve the yield rate.

Mesh recommendation for sieving machine for copper electrolytic powder

|

Purpose |

Recommended mesh range |

Corresponding particle size |

Description |

|

Remove large particles |

40 mesh~ 80 mesh |

180~ 450 μm |

Preliminary screening of impurities and agglomerates to ensure product purity |

|

Conventional copper powder grading |

100 mesh~200 mesh |

75~150μm |

General-grade grading screen configuration, used for conventional purposes such as electrical engineering and electric carbon |

|

Fine copper powder screening |

200 mesh~325 mesh |

45~75 μm |

Prevent screen clogging and improve fine copper powder screening efficiency |

|

Ultra-fine copper powder screening |

400 mesh~500 mesh and above |

≤38μm |

High requirements for screening accuracy and equipment performance, suitable for electronic copper powder and other occasions |

|

Multi-level particle size control |

Multi-layer screen combination (such as 60/100/200 mesh) |

Multi-particle size segment |

Multi-level separation of coarse powder, finished powder and fine powder at one time |

What can the sieving machine for copper electrolytic powder be used for?

Sieving machines for copper electrolytic powder are widely used in many fields, especially in battery manufacturing, electronic components and electroplating industries. In battery manufacturing, sieving machines are used to grade copper electrolytic powder to ensure uniform particles, thereby improving the conductivity and performance of the battery. In the production of electronic components, sieving machines help separate copper powders of different particle sizes to meet the requirements of different components and ensure product quality and stability.

In addition, in the electroplating industry, the screening of copper electrolytic powder helps remove impurities and improve the purity of the electroplating solution, so that the electroplating layer is smoother and more uniform. Through these applications, the sieving machine for copper electrolytic powder not only improves production efficiency, but also optimizes product quality.

How to choose a sieving machine for copper electrolytic powder

For electrolytic copper powder, a metal powder with high requirements for purity and particle size, screening equipment with good airtightness, high screening efficiency and the ability to handle fine powder, such as ultrasonic vibrating screen or swing screen, is usually selected.

The sieving machine for copper electrolytic powder is a fine screening equipment with high requirements for screening accuracy and equipment cleanliness. The specific selection needs to be determined according to the particle size distribution, output requirements and process requirements of the copper powder. The most widely used model at present is the stainless steel ultrasonic vibrating screen, which is suitable for grading electrolytic copper powder with mesh size of 200~500. For powders with extremely high mesh size or serious viscosity problems, airflow screens can also be considered as a supplement.

In actual selection, it is recommended that you combine the specific particle size, characteristics, required processing volume, quality requirements of the final product and budget of the copper electrolytic powder, and consult a professional screening equipment supplier for small batch testing to select the sieving machine that best suits your production line.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Drained vegetable vibrating screen

Drained vegetable vibrating screen is a screening device used for the preliminary dehydration of...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.