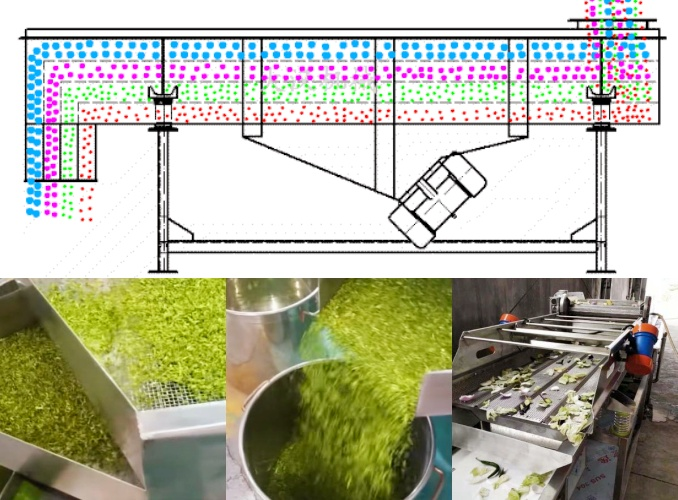

Drained vegetable vibrating screen

What is Drained vegetable vibrating screen?

Drained vegetable vibrating screen is a screening device used for the preliminary dehydration of washed vegetables, suitable for the assembly line processing of leafy vegetables, root vegetables, or sliced vegetables. Through high-frequency vibration, the separation of water and vegetables is quickly achieved, the screening effect is efficient, and the dehydration rate can reach more than 90%. When it is working, vegetables enter from the feed end, and under the high-frequency vibration generated by the vibration motor, water droplets on the surface quickly fall off. It is often used for draining leafy vegetables and root vegetables after blanching or washing, such as spinach, kelp shreds, lotus root slices, water chestnuts, etc.

The mesh size of the screen is usually between 32-200 mesh (0.075-0.5mm). For leafy vegetables (such as spinach and rapeseed), it is recommended to use a coarse mesh screen of 32-60 mesh (0.5-0.3mm), which can effectively separate impurities and avoid leaf damage; for root vegetables (such as carrots and potatoes), it is suitable to use a medium-fine screen of 80-120 mesh (0.2-0.125mm), which can remove mud and sand and protect the integrity of the epidermis; berries (such as tomatoes and strawberries) require a fine screen of 150-200 mesh (0.1-0.075mm) to achieve gentle sorting. The screen frame should be made of 304 stainless steel, with a mesh diameter of 0.1-0.15mm, and an inclined installation of 15°-20° can improve the screening efficiency.

What are the disadvantages of the drained vegetable vibrating screen?

Although the drained vegetable vibrating screen is efficient and practical in vegetable processing, it also has some disadvantages. For example, some fragile vegetables (such as tender leafy vegetables) may be slightly damaged, especially when the vibration frequency is too high or the mesh size is improper, resulting in damage to the surface of the vegetables or affected texture.

Unable to achieve complete drying: The vibrating screen is mainly used to remove most of the moisture on the surface of vegetables, but it cannot achieve deep dehydration or even complete drying like a centrifugal dehydrator or dryer. For products that need to reach very low moisture content (such as dehydrated dried vegetables), other drying equipment is still required.

Limited effect on specific vegetables: For vegetables with extremely high water content, very soft texture or irregular shape, and easy to stick together (for example, some leafy vegetables are easy to entangle with each other during the drainage process), the vibration drainage effect may not be as expected, and manual assistance or other dehydration methods may still be required.

Complex production line requirements: A single vibrating screen may not meet the diverse processing requirements and needs to be matched with other equipment, increasing the difficulty of system integration. For specific application scenarios, it is necessary to reasonably select models and parameters to reduce the impact of these shortcomings.

Common model parameter table of drained vegetable vibrating screen

|

Model |

Screen surface size (mm) |

Number of layers |

Power (kW) |

Mesh size (mm) |

Processing capacity (kg/h) |

|

DZSF-520 |

500×2000 |

1 |

0.4×2 |

2~10 |

300~800 |

|

DZSF-1020 |

1000×2000 |

1 |

0.75×2 |

2~10 |

800~2000 |

|

DZSF-1030 |

1000×3000 |

1 |

1.1×2 |

2~10 |

1500~3000 |

|

DZSF-1230 |

1200×3000 |

1 |

1.5×2 |

2~10 |

2000~4000 |

Recommended mesh size of drained vegetable vibrating screen

|

Vegetable type |

Common form |

Recommended mesh size |

Sieve hole diameter (mm approximate) |

Description |

|

Spinach, Chinese cabbage |

whole leaves, cut sections |

4~6 mesh |

4.0~5.0 mm |

Ensure that leafy vegetables do not block the net and facilitate drainage |

|

Lettuce, lettuce |

shredded, cut sections |

5~8 mesh |

2.5~4.0 mm |

A certain volume, moderate mesh size is required |

|

Carrots, potatoes |

shredded, sliced |

6~10 mesh |

2.0~3.5 mm |

More water, regular particle shape |

|

Shiitake mushrooms, fungus |

sliced or torn |

5~8 mesh |

3.0~4.0 mm |

Maintain integrity and avoid leakage |

|

Apple slices, pear slices |

sliced |

6~10 mesh |

2.0~3.5 mm |

Fruits have more water and need to be drained quickly |

|

Lettuce shreds, celery segments |

thin threads, strips |

8~10 mesh |

2.0~2.5 mm |

Prevent leakage and facilitate water discharge |

What is the main purpose of the drained vegetable vibrating screen?

The main purpose of the drained vegetable vibrating screen is to efficiently and quickly remove excess water from the surface of vegetables, thereby creating optimal conditions for subsequent food processing, storage, and transportation, while maximizing the quality and integrity of vegetables. Compared with natural draining or manual wiping, the vibrating screen can greatly shorten the draining time and speed up the operation of the entire production line. Removing excess water can prevent bacteria from growing and extend the shelf life of vegetables. For quick-frozen vegetables, reducing water can prevent excessive ice crystals from affecting the taste; for dehydrated vegetables, it can reduce drying energy consumption and improve dehydration efficiency.

What can the vegetable vibrating screen for draining be used for

The vegetable vibrating screen for draining is mainly used for the initial dehydration of washed vegetables. It is widely used in clean vegetable processing, central kitchens, quick-frozen vegetable production lines, dehydrated vegetable pretreatment, supermarket fresh food distribution centers and other scenarios. This equipment is often arranged between the washing machine and the air dryer to quickly drain the freshly washed vegetables such as lettuce, Chinese cabbage, spinach, carrot shreds, etc., to reduce the load of subsequent air drying or dehydration equipment.

In central kitchens or group catering companies, the vibrating screen for draining can also be used to drain the cut vegetables briefly to avoid water accumulation when the dishes are packaged, affecting the taste and preservation effect. Some food processing plants also use it to remove moisture from washed fruits, such as apple slices, potato slices, mushrooms, etc., in the assembly line processing links, with automatic feeding and packaging systems to improve the level of production automation.

How to choose a drained vegetable vibrating screen

When choosing a drained vegetable vibrating screen, common screening forms include linear vibrating screens and circular vibrating screens (also known as rotary vibrating screens), which have obvious differences in structure and applicable scenarios.

If the output is large, the vegetables are irregular in shape, and the assembly line needs to be operated automatically, it is recommended to use a linear vibrating screen.

If the output is small, the vegetables are chopped finely, the space is limited, or the materials are frequently changed, a circular vibrating screen can be considered.

Draining Vegetable Vibrating Screen Customer Case

For the drainage of dehydrated vegetables, a specially designed vibrating drain screen is used. The vegetable raw materials are placed in a detachable drain tray, and then the drain tray is placed in the vibration seat. After starting the equipment, the drive motor drives the rotating shaft to rotate, and the cam on the rotating shaft will lift the vibration seat. Then, the vibration seat moves downward quickly under the action of the support spring and hits the support seat, thereby achieving vibration drainage. In addition, the equipment is also equipped with a movable covering structure to prevent vegetables from flying out during the vibration drainage process, effectively solving the problem that the traditional static drainage method is time-consuming and easy to cause vegetable corruption.

Drained vegetable vibrating screen industrial process

In food processing, the Drained vegetable vibrating screen removes surface moisture and residual liquid from vegetables through rapid vibration. The specific process is as follows:

Feeding: The drained vegetables are fed into the feed port of the vibrating screen at a uniform speed through the conveyor belt. By adjusting the conveyor belt speed and the vibrating screen feed baffle, the vegetables are evenly distributed to avoid accumulation.

Vibration dehydration: The high-frequency vibration motor drives the stainless steel screen to produce a throwing motion. The vegetables jump forward on the screen surface inclined at 10°-15°. The surface moisture and fine residues pass through the 0.5-2mm aperture screen and fall into the lower water collection tank to achieve solid-liquid separation. The vibration frequency is adjustable (800-1500 times/minute) and is suitable for different types of vegetables (such as leafy vegetables and root vegetables).

Grading (optional): When configuring a multi-layer screen, the upper screen holes are larger, which are used to intercept large-sized vegetables (such as broccoli), and the lower screen holes are smaller, which separates broken pieces or small varieties (such as peas), achieving multi-level sorting.

Discharging: The dehydrated vegetables slide from the end of the screen into the receiving hopper, and enter the packaging or quick-freezing process through the diversion trough. The remaining water is collected and processed in the water collection tank.

The drained vegetable vibrating screen is an indispensable equipment on the vegetable processing line. It uses efficient vibration mechanical action to quickly remove the attached moisture on the surface of the vegetables while gently treating the materials, providing dry or low-water content raw materials for subsequent processing steps, significantly improving production efficiency and product quality. When choosing, it is necessary to determine the specifications and configuration of the equipment according to the specific vegetable type, production capacity requirements, and the connection between the previous and next processes.

-

Granules, powders, and paddle materials can be used.

-

Designed for precise grading, peeling or grading of wet and dry applications

-

Quick Release Clamp for Vibratory Screener

Small size, does not occupy space, easy to move.

-

Quickly separate the impurities in the tea, grading tea of different size & shapes.

-

Why use gas protection ultrasonic sieving machine metal powder?

Metal powder refers to a group of metal particles with a size of less than 1mm, including single...

-

What is the price of emulsion filtration shaker?

Emulsion filtration shaker is a screening equipment used in the emulsion industry, mainly used for...

-

Vegetable vibrating screen for draining water

Vegetable vibrating screen for draining water for draining water is a kind of equipment used in the...

-

Small Vibrating Sieve Machine For Very Fine Herbal Dry Powder

Small vibrating sieve for very fine herbal dry powder is a screening equipment designed for the char...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.